Preparation method for tetra-alkyl ammonium hydroxide

A technology of ammonium hydroxide and tetraalkylammonium salt, which is applied in the direction of cells, electrolysis process, electrolysis components, etc., can solve the problems of corrosion current efficiency of electrolytic cell plates, high halogen content, and reduced reaction efficiency, and achieves easy large-scale Industrial production, excellent life and electrochemical performance, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

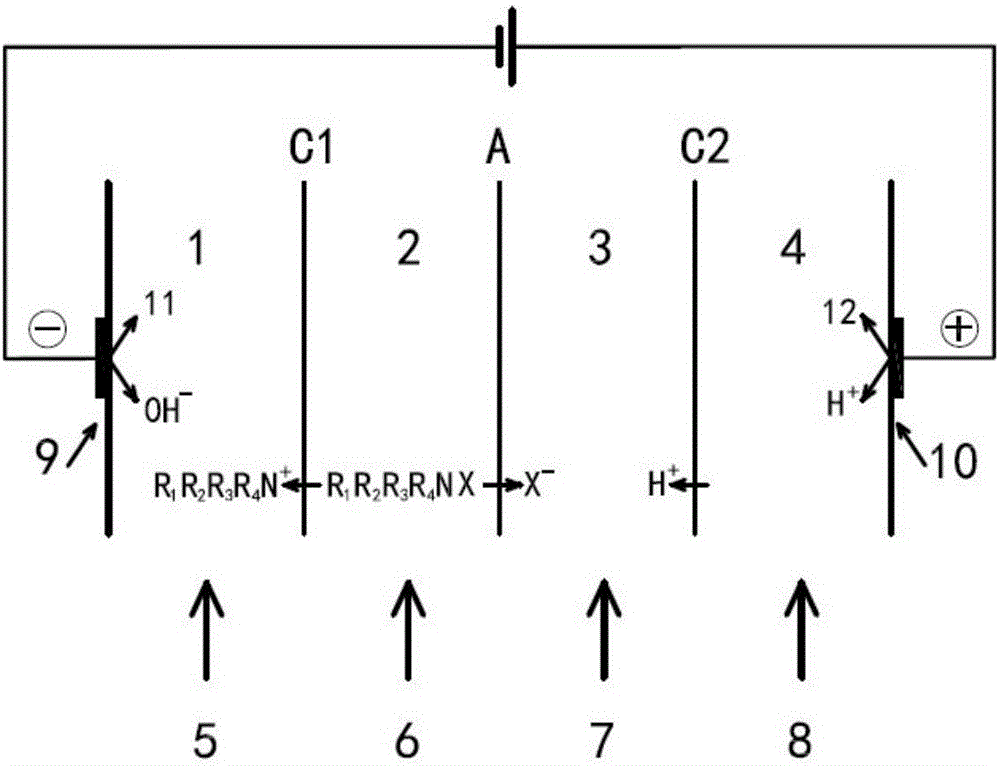

Method used

Image

Examples

Embodiment 1

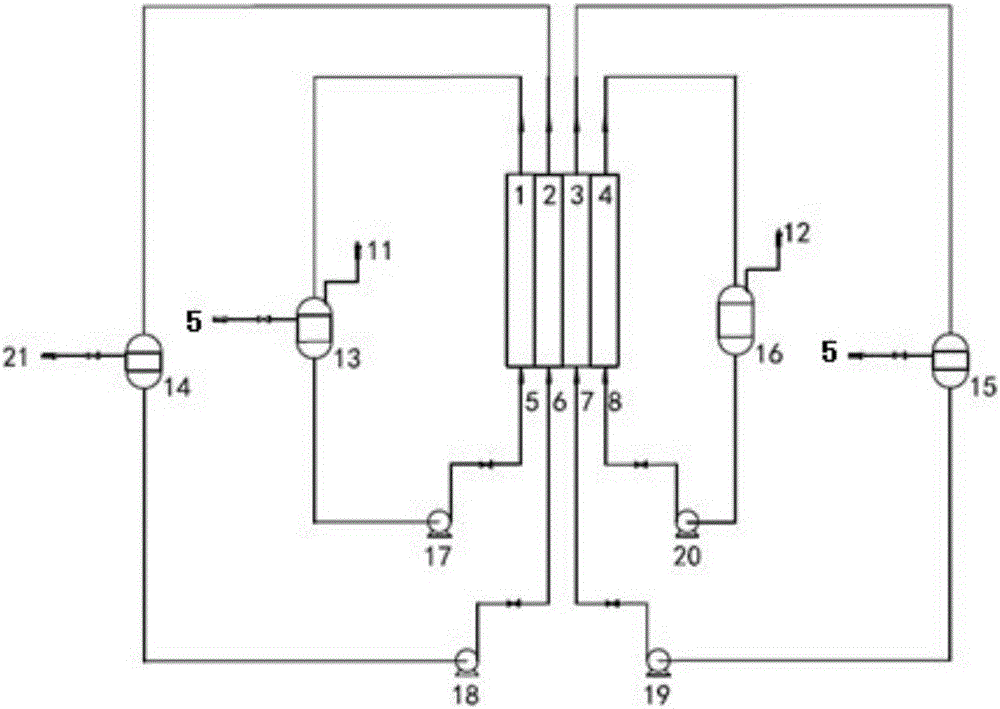

[0030] In this embodiment, 10L of tetrabutylammonium bromide solution of 0.2mol / L is added to the salt solution storage tank 14, 10L of pure water is added to the catholyte storage tank 13, and 0.8mol / L is added to the acid solution storage tank 15. 10L of HBr solution, add 0.3mol / L of H in the anolyte storage tank 16 2 SO 4 Solution 10L, turn on each circulating pump, adjust the flow rate to 0.2cm / s, then turn on the power, the current is gradually increased to 20A, and electrolysis starts. Tetrabutylammonium bromide solid maintains concentration, controls each chamber solution temperature 20 ℃, obtains the tetrabutylammonium hydroxide solution that product concentration is 0.8mol / L, and wherein bromide ion content is 8.9ppm, and metal ion content is 87ppb; Current efficiency is 44.7%.

Embodiment 2

[0032] In this embodiment, 10 L of tetrabutylammonium bromide solution of 1.0 mol / L is first added in the salt liquid storage tank 14, 10 L of pure water is added in the catholyte storage tank 13, and 0.2 mol / L is added in the acid liquid storage tank 15 10L of HBr solution, add 0.3mol / L of H in the anolyte storage tank 16 2 SO 4 Solution 10L, turn on each circulating pump, adjust the flow rate to 1.0cm / s, then turn on the power, the current is gradually increased to 10A, and electrolysis starts. Tetrabutylammonium bromide solid maintains the concentration, and the solution temperature in each chamber is controlled to 60°C. A tetrabutylammonium hydroxide solution with a finished product concentration of 0.2mol / L was obtained, wherein the content of bromide ions was 6.3ppm, the content of metal ions was 73ppb; the current efficiency was 63.2%.

Embodiment 3

[0034] In this embodiment, 10L of tetrapropylammonium bromide solution of 1.5mol / L is first added in the salt solution storage tank 14, 10L of pure water is added in the catholyte storage tank 13, and 0.2mol / L is added in the acid solution storage tank 15 10L of HBr solution, add 0.3mol / L of H in the anolyte storage tank 16 2 SO 4 Solution 10L, turn on each circulation pump, adjust the flow rate to 1.0cm / s, then turn on the power, the current is gradually increased to 15A, and electrolysis starts. Tetrapropylammonium bromide solid maintains concentration, adjusts 60 ℃ of solution temperature in each chamber, obtains the tetrapropylammonium hydroxide solution that product concentration is 0.2mol / L, and wherein bromide ion content is 5.3ppm, and metal ion content is 64ppb; The efficiency is 75.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com