Method for separating methionine from mixed solution of methionine salt and carbonate by using bipolar membrane electrodialysis

A bipolar membrane electrodialysis and mixed solution technology, applied in sulfide preparation, organic chemistry, etc., can solve the problems of complex process, small output, complicated purification process, etc., and achieve the effect of easy operation, high recovery efficiency and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

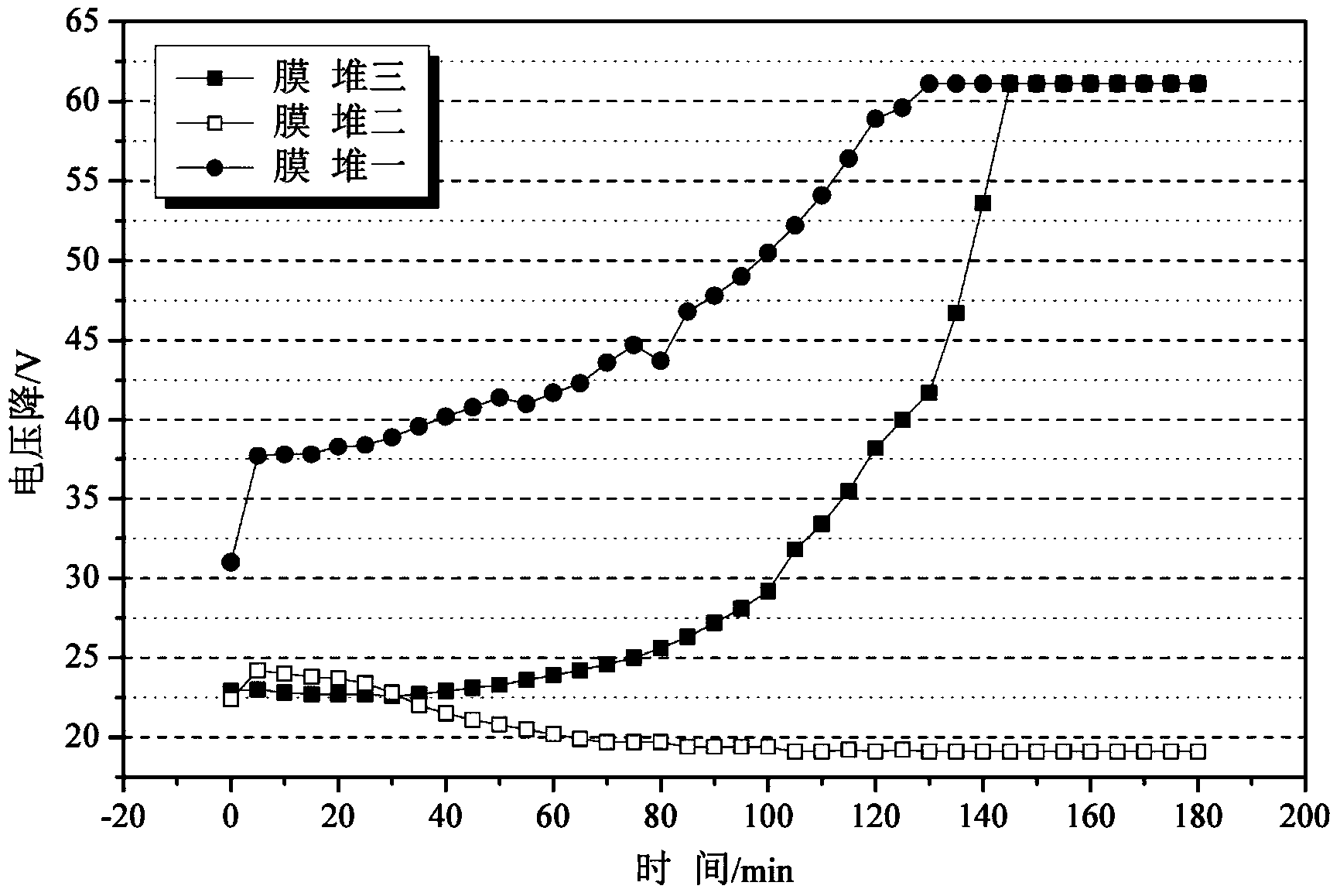

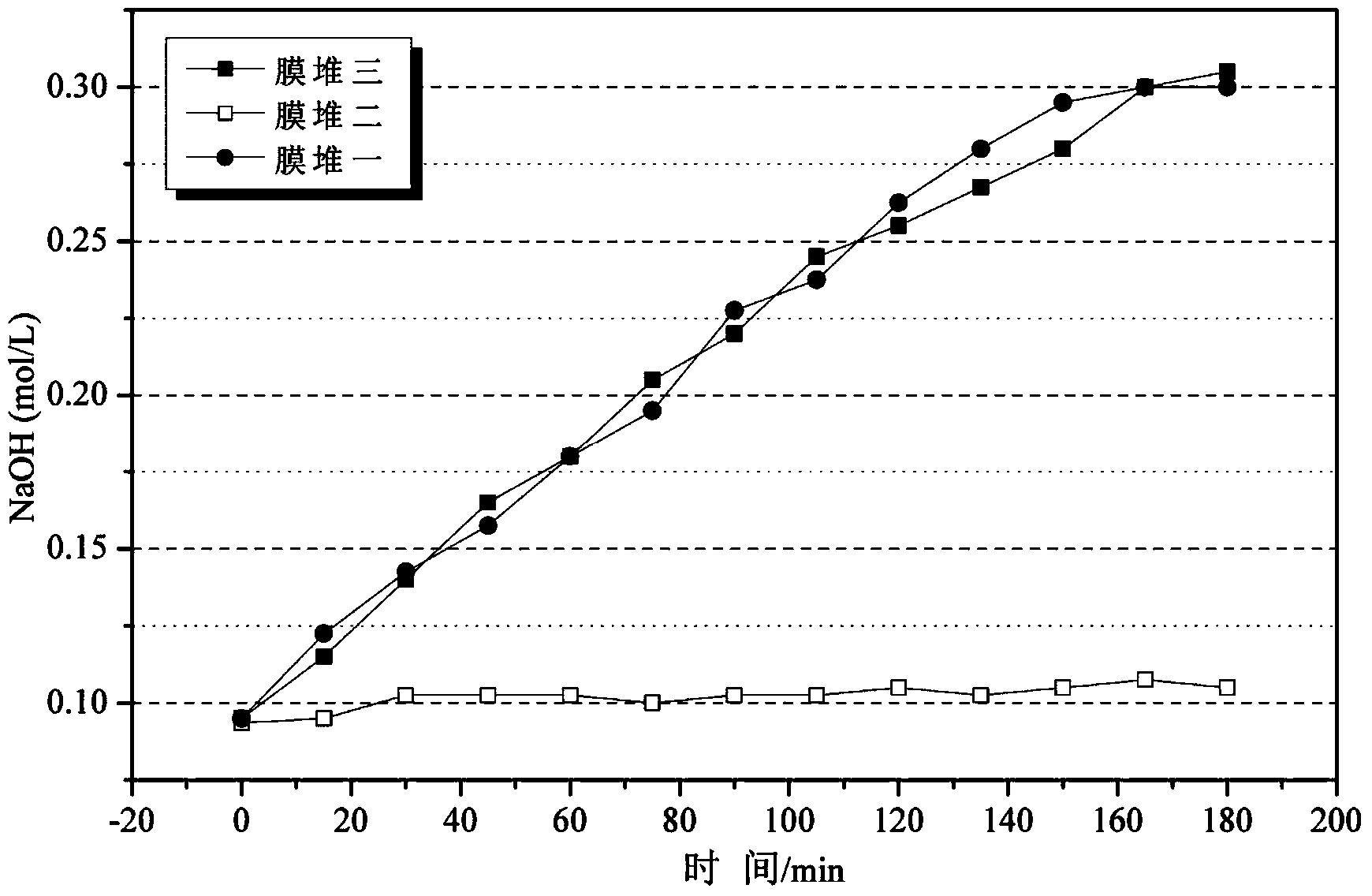

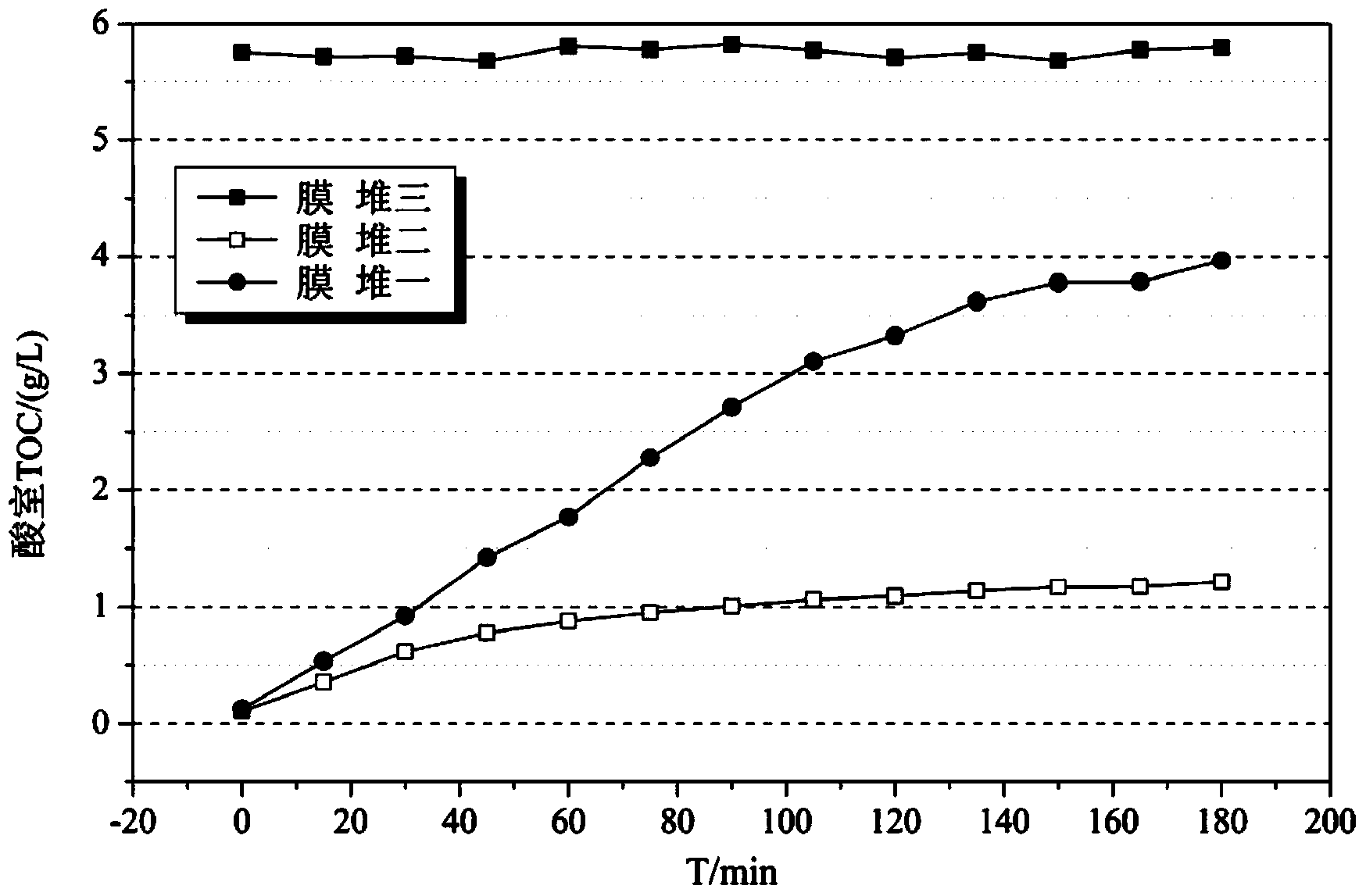

[0036] The raw material used in this example is a mixed solution of sodium methionine and sodium carbonate, wherein the concentration of sodium methionine is 0.101 mol / L, and the concentration of sodium carbonate is 0.203 mol / L.

[0037] This embodiment utilizes bipolar membrane electrodialysis to separate methionine from the mixed solution of sodium methioninate and sodium carbonate according to the following steps:

[0038] Such as Figure 4 As shown, a bipolar membrane electrodialysis system (named membrane stack one in this embodiment) is set. The bipolar membrane electrodialysis system is composed of electrode chambers on both sides and a chamber sandwiched between the electrode chambers on both sides. It includes two chamber units, each chamber unit is composed of an alkali chamber, a feed liquid chamber and an acid chamber arranged in sequence, and a cation exchange membrane is used as the interval between the alkali chamber and the feed liquid chamber, and between the ...

Embodiment 2

[0049] The raw material used in this example is a mixed solution of sodium methionine and sodium carbonate, wherein the concentration of sodium methionine is 0.106 mol / L, and the concentration of sodium carbonate is 0.148 mol / L.

[0050] This embodiment utilizes bipolar membrane electrodialysis to separate methionine from the mixed solution of sodium methioninate and sodium carbonate according to the following steps:

[0051] Such as Figure 5 As shown, a bipolar membrane electrodialysis system (named membrane stack two in this embodiment) is set. The bipolar membrane electrodialysis system is composed of electrode chambers on both sides and a chamber sandwiched between the electrode chambers on both sides. It includes two chamber units, each chamber unit is composed of an alkali chamber and an acid chamber arranged in sequence. The alkali chamber of the chamber unit is separated by a bipolar membrane; the chamber unit adjacent to the electrode chambers on both sides is separ...

Embodiment 3

[0062] The raw material used in this example is a mixed solution of sodium methionine and sodium carbonate, wherein the concentration of sodium methionine is 0.096 mol / L, and the concentration of sodium carbonate is 0.158 mol / L.

[0063] This embodiment utilizes bipolar membrane electrodialysis to separate methionine from the mixed solution of sodium methioninate and sodium carbonate according to the following steps:

[0064] Such as Figure 6 As shown, a bipolar membrane electrodialysis system (named membrane stack three in this embodiment) is set. The bipolar membrane electrodialysis system is composed of electrode chambers on both sides and a chamber sandwiched between the electrode chambers on both sides. It includes two chamber units, each chamber unit is composed of an alkali chamber and an acid chamber arranged in sequence, the alkali chamber and the acid chamber are separated by a cation exchange membrane, the acid chamber of the first chamber unit and the next chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com