Wet process phosphoric acid purification technology of nonphosphate precipitation

A wet-process phosphoric acid, non-phosphate technology, applied in the field of phosphorous chemical industry, can solve the problems of the degradation of phosphoric acid product quality, low impurity removal rate, troublesome deep purification, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

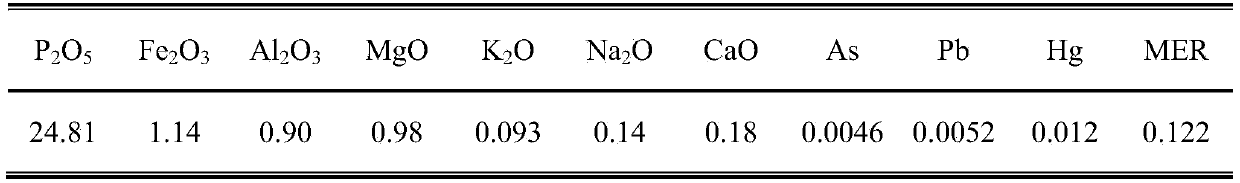

Embodiment 1

[0027] Take 10 tons of dilute acid in the aging tank, add non-phosphate precipitation wet-process phosphoric acid purification agent ZZH-1 (sodium fluoride, 102kg), ZZH-2 (potassium carbonate, 123kg), ZZH-3 (phosphorus pentasulfide, 8kg) , ZZH-4 (8-hydroxyquinoline, 25kg), ZZH-5 (potassium sulfate, 56kg), the phosphoric acid temperature is 26°C, the reaction time is 12min, and the stirring rate is 26r / min. After treatment, the removal rates of wet-process iron phosphate, magnesium, and aluminum are respectively above 97.19%, 72.68%, and 15.30%. 2 O meter) are respectively 0.021%, 0.078%, sulfate radical 0.15%, P 2 o 5 The recovery rate is 98.7%.

Embodiment 2

[0029] Take 10 tons of dilute acid in the aging tank, add non-phosphate precipitation wet-process phosphoric acid purification agent ZZH-1 (sodium fluoride, 30kg; magnesium fluoride, 45kg), ZZH-2 (ammonium carbonate, 68kg), ZZH- 3 (potassium sulfide, 3kg), ZZH-4 (8-hydroxyquinoline, 7kg; potassium oxalate, 15kg), ZZH-5 (sodium sulfate, 88kg), the temperature of phosphoric acid is 33°C, the reaction time is 45min, and the stirring rate is 89r / min. After treatment, the removal rates of wet-process iron phosphate, magnesium, and aluminum are respectively above 97.54%, 71.33%, and 15.36%. 2 O meter) are respectively 0.022%, 0.080%, sulfate radical 0.14%, P 2 o 5 The recovery rate is 98.9%.

Embodiment 3

[0031] Take 10 tons of dilute acid in the aging tank, add non-phosphate precipitation wet-process phosphoric acid purification agent ZZH-1 (hydrogen fluoride, 123kg; beryllium fluoride, 12kg), ZZH-2 (potassium carbonate, 66kg; sodium carbonate, 11kg) , ZZH-3 (sodium sulfide, 3kg), ZZH-4 (sodium cyanide, 12kg; potassium oxalate, 44kg), ZZH-5 (potassium sulfate, 11kg; ammonium sulfate, 28kg; magnesium sulfate, 15kg), the phosphoric acid temperature is 55°C, reaction time 36min, stirring speed 156r / min. After treatment, the removal rates of wet-process iron phosphate, magnesium, and aluminum are respectively above 98.14%, 71.33%, and 16.70%. 2 O meter) are respectively 0.018%, 0.074%, sulfate radical 0.14%, P 2 o 5 The recovery rate is 98.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com