Low-odor PVC powder for automotive upholstery and preparing method thereof

A low-odor, PVC resin technology, applied in the field of low-odor PVC powder for automotive interior parts and its preparation, can solve the problem that the mechanical properties of PVC films are greatly affected, the odor of plasticizers cannot be effectively controlled, and the aging resistance is relatively poor. Large and other problems, to achieve the effect of small appearance impact, uniform thickness, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

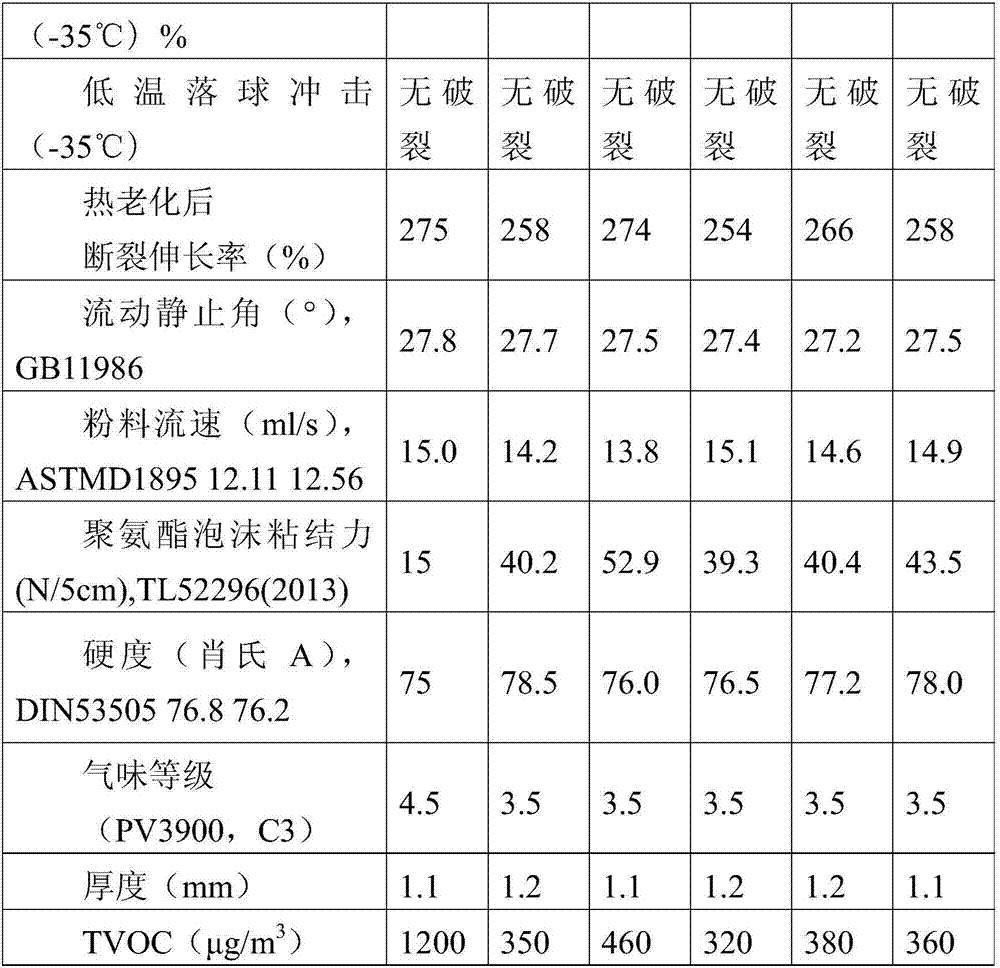

Examples

Embodiment 1

[0046] (1) Stir the fumed silica deodorant (with a particle size of 5 microns) and the aluminate coupling agent in a mixer for 15 minutes according to a mass ratio of 100:3, and then discharge;

[0047] (2) 100 kilograms of PVC resin (the degree of polymerization of PVC resin is 2000, and the average particle diameter is 200 μ m), 4 kilograms of phosphite, 2 kilograms of phosphate ester heat stabilizer compound, 0.2 kilogram of citric acid, 0.2 kilogram of zinc oxide Light stabilizer compound and 0.4 kg of hindered phenol antioxidant, 0.2 kg of phosphite antioxidant compound were added to the high mixer and heated and stirred for 2 minutes; when the temperature rose to 95 ° C, 10 kg of CPE (chlorine Polyethylene), stirred for 2 minutes; when the temperature increased to 120°C, 30 kg of plasticizers (70% trioctyl trimellitate, 30% epoxy soybean oil) were added, and continued to stir for 5 minutes; stop Heating and stirring, when the temperature dropped to 100°C, restarted stirr...

Embodiment 2

[0051] (1) Stir the nano-calcium carbonate (10 microns in particle size) deodorant and titanate coupling agent in a mixer for 15 minutes according to the mass ratio of 100:1, and then discharge;

[0052] (2) 100 kilograms of PVC resin (the degree of polymerization of PVC resin is 1000, and the average particle diameter is 100), 3 kilograms of zinc stearate, 3 kilograms of calcium stearate, 2 kilograms of hydrotalcite heat stabilizer compound, 0.3 Add 1 kg of zinc oxide and 0.2 kg of hindered amine light stabilizer compound, 0.2 kg of hindered phenol antioxidant, and 0.1 kg of phosphite antioxidant compound into a high-mixer and heat and stir for 2 minutes. When the temperature rises to 95 Add 10 kg of toughening agent (EVA, ethylene-vinyl acetate polymer) at ℃, stir for 2 minutes; add 30 kg of plasticizer (80% trioctyl trimellitate, Epoxy fatty acid methyl ester 20%), continue to stir for 5 minutes; Then stop heating and stirring, and start stirring for 3 minutes when the temp...

Embodiment 3

[0056] (1) Mix deodorant with nano-zinc oxide (particle size: 10 microns), precipitated silica (particle size: 20 microns), fumed silica (particle size: 5 microns) and aluminate coupling agent According to the ratio of mass ratio 30:30:40:3, stir in the mixer for 10 minutes, and discharge;

[0057] (2) 100 kilograms of PVC resin (the degree of polymerization of PVC resin is 500, and the average particle diameter is 50 μm), 8 kilograms of phosphoric acid ester, 2 kilograms of polyol heat stabilizer compound, 0.5 kilogram of citric acid, 0.5 kilogram of zinc oxide Stabilizer, 0.5 kg of aromatic amine antioxidant and 0.5 kg of phosphite antioxidant are added to the high mixer and heated and stirred for 2 minutes. When the temperature rises to 100 °C, add 20 kg of CPE (chlorinated polyethylene), and stir 2 minutes; Add 30 kilograms of plasticizers (trioctyl trimellitate 70%, epoxy castor oil 30%) when temperature is raised to 120 ℃, and continue to stir for 4 minutes; Stop heating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com