PVC sheet and preparation method thereof

A technology of sheets and parts by weight, which is applied in the field of PVC sheets and its preparation, can solve problems such as low impact strength and optimization of PVC impact strength performance, achieve good compatibility, good impact strength and toughness, and improve thermal oxygen Effect of Aging Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A PVC sheet, its raw material components are as shown in Table 1 in parts by weight.

[0049] Among them, tributyl citrate is used as internal lubricant, SG-70s is used as external lubricant, and triethylene glycol bis[3-(3,5-di-tert-butyl-4-hydroxy)phenyl]propionate is used as antioxidant .

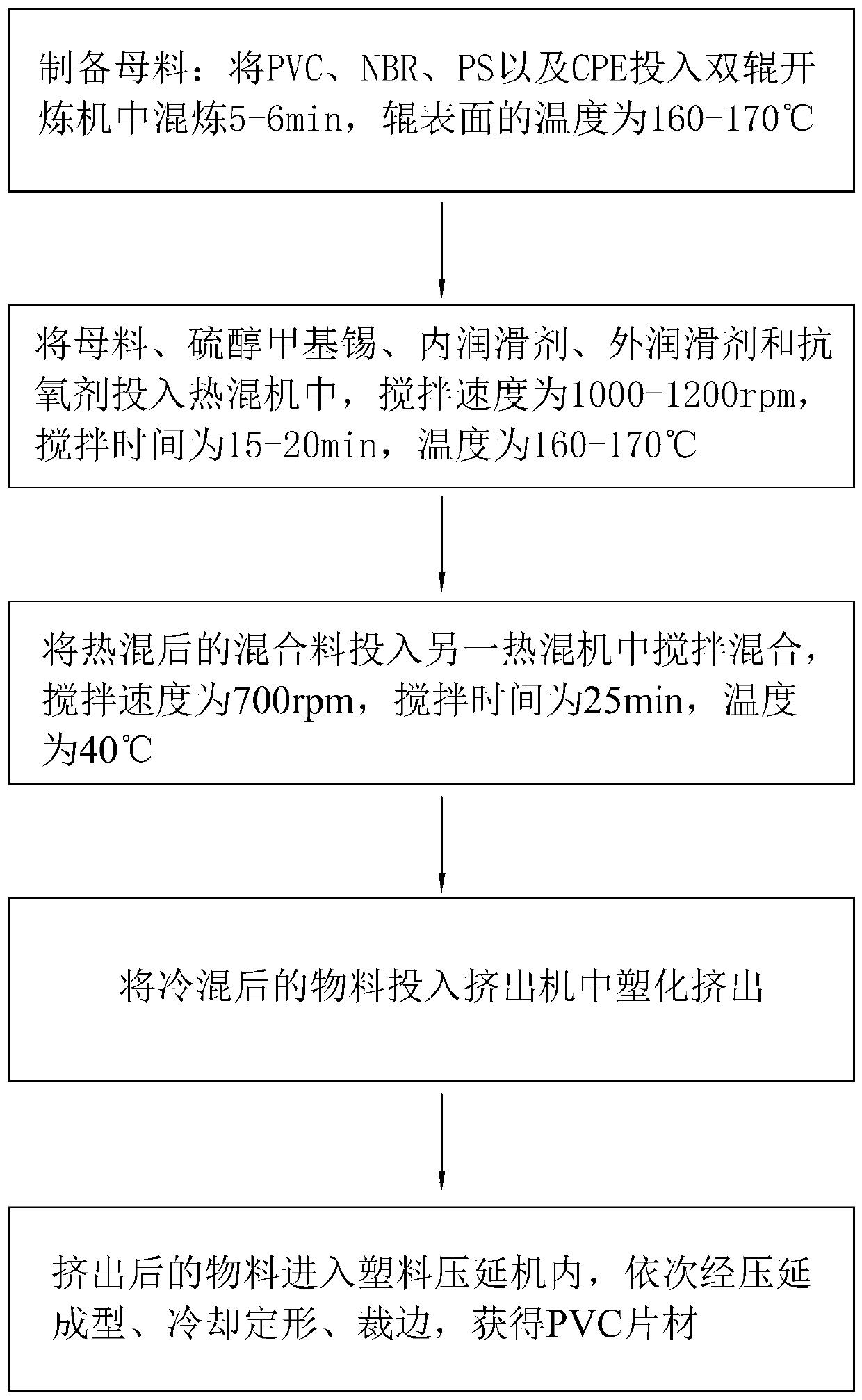

[0050] Such as figure 1 Shown, the preparation method of this PVC sheet comprises the following steps:

[0051] S1, preparation of masterbatch: put PVC, NBR, PS and CPE into a two-roll mill and knead for 5 minutes, and the temperature of the roller surface is 160°C;

[0052] S2, hot mixing: mix masterbatch, methyl tin mercaptide, tributyl citrate, SG-70s and bis[3-(3,5-di-tert-butyl-4-hydroxy)phenyl] triethylene glycol propionate Put the ester into a thermomixer and stir to mix, the stirring speed is 1000rpm, the stirring time is 20min, and the temperature is 160°C;

[0053] S3, cold mixing: Put the mixed material after hot mixing into another hot mixer and stir and mix, the s...

Embodiment 2

[0057] A PVC sheet, its raw material components are as shown in Table 1 in parts by weight.

[0058] Among them, tributyl citrate is used as internal lubricant, SG-70s is used as external lubricant, and triethylene glycol bis[3-(3,5-di-tert-butyl-4-hydroxy)phenyl]propionate is used as antioxidant .

[0059] The preparation method of this PVC sheet comprises the following steps:

[0060] S1, preparation of masterbatch: put PVC, NBR, PS and CPE into a double-roll mill and knead for 6 minutes, and the temperature of the roller surface is 160°C;

[0061] S2, hot mixing: mix masterbatch, methyl tin mercaptide, tributyl citrate, SG-70s and bis[3-(3,5-di-tert-butyl-4-hydroxy)phenyl] triethylene glycol propionate Put the ester into a thermomixer and stir to mix, the stirring speed is 1200rpm, the stirring time is 15min, and the temperature is 160°C;

[0062] S3, cold mixing: Put the mixed material after hot mixing into another hot mixer and stir and mix, the stirring speed is 700rp...

Embodiment 3

[0066] A PVC sheet, its raw material components are as shown in Table 1 in parts by weight.

[0067] Among them, tributyl citrate is used as internal lubricant, SG-70s is used as external lubricant, and triethylene glycol bis[3-(3,5-di-tert-butyl-4-hydroxy)phenyl]propionate is used as antioxidant .

[0068] The preparation method of this PVC sheet comprises the following steps:

[0069] S1, preparation of masterbatch: put PVC, NBR, PS and CPE into a double-roll mill and knead for 6 minutes, and the temperature of the roller surface is 170°C;

[0070] S2, hot mixing: mix masterbatch, methyl tin mercaptide, tributyl citrate, SG-70s and bis[3-(3,5-di-tert-butyl-4-hydroxy)phenyl] triethylene glycol propionate Put the ester into a thermomixer and stir to mix, the stirring speed is 1200rpm, the stirring time is 15min, and the temperature is 170°C;

[0071] S3, cold mixing: Put the mixed material after hot mixing into another hot mixer and stir and mix, the stirring speed is 800rp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com