Polychloroethylene / layered double hydroxide nano composite material and preparation thereof

A technology of nanocomposite materials and layered hydroxides, which is applied in the field of polyvinyl chloride/layered double hydroxide nanocomposites, can solve problems such as difficulty in industrial scale-up, influence on polymerization process and mechanism, and complex preparation process , to achieve significant modification effect, improve composite effect, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

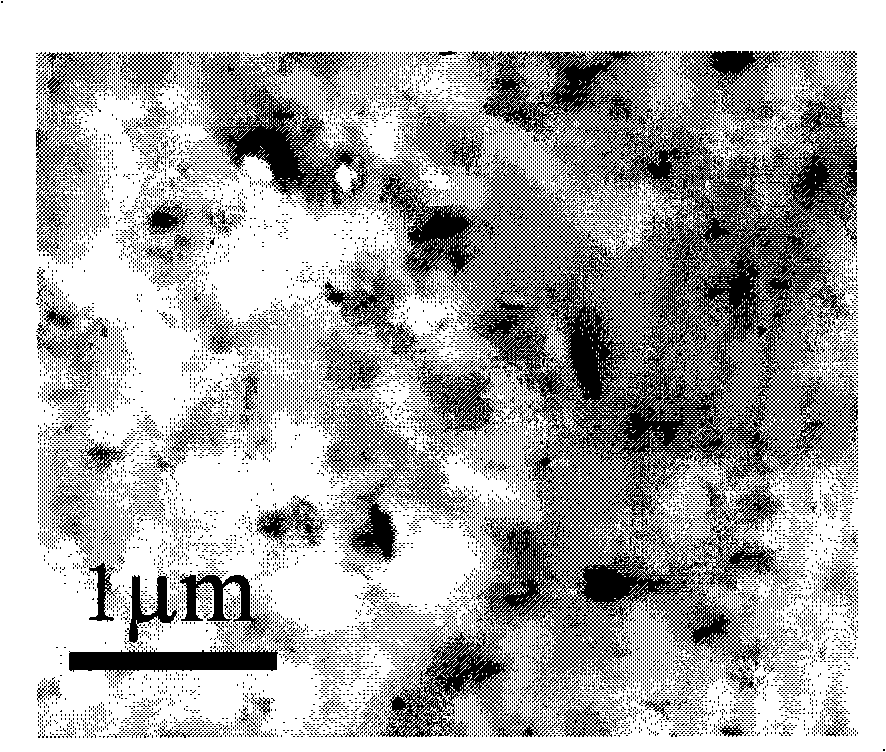

Image

Examples

Embodiment 1

[0029] Embodiment 1, preparation polyvinyl chloride / layered double hydroxide nanocomposite material

[0030]Under nitrogen condition, slowly drip the aqueous solution containing 0.02mol magnesium nitrate and 0.01mol aluminum nitrate (Mg / Al=2) into 200ml aqueous solution containing 0.015mol sodium lauryl sulfate and 0.02mol sodium hydroxide by 50ml, Stir vigorously until the dropwise addition is complete. During the whole dropping process, use 1mol / L sodium hydroxide solution to adjust the pH value of the system to always be about 10, then raise the temperature to 80°C, keep the temperature constant for 6h, wash, filter, and vacuum dry for 24 hours to obtain Surface-modified LDHs.

[0031] Add 1 part of surface organically modified LDHs to cyclohexanone, and ultrasonically disperse for 30 minutes to obtain a stable dispersion with a concentration of 5 g / L; then add the obtained dispersion to a tetrahydrofuran solution in which 100 parts of PVC are completely dissolved, The con...

Embodiment 2

[0033] Embodiment 2, preparation polyvinyl chloride / layered double hydroxide nanocomposite material

[0034] Under nitrogen, slowly drop 50ml of an aqueous solution containing 0.06mol magnesium nitrate and 0.02mol aluminum nitrate (Mg / Al=3) into 200ml of an aqueous solution containing 0.03mol sodium dodecylsulfonate and 0.06mol potassium hydroxide , vigorously stirred until the dropwise addition is complete, the pH value of the system is always adjusted to about 10 with 1mol / L sodium hydroxide solution during the whole dropwise addition process, and then the temperature is raised to 70°C, kept at a constant temperature for 12h, washed, filtered, and vacuum-dried for 36 hours to obtain Surface-modified LDHs.

[0035] Add 3 parts of surface organically modified LDHs to methyl phthalate, and disperse at high speed for 5 minutes to obtain a stable dispersion with a concentration of 10 g / L; then add the resulting dispersion to completely dissolve 100 parts of PVC In the tetrahydro...

Embodiment 3

[0037] Embodiment 3, preparation polyvinyl chloride / layered double hydroxide nanocomposite material

[0038] Under nitrogen, slowly drop 50ml of an aqueous solution containing 0.04mol magnesium nitrate and 0.01mol aluminum nitrate (Mg / Al=4) into 200ml of an aqueous solution containing 0.02mol sodium stearate and 0.04mol potassium hydroxide, and stir vigorously Until the dropwise addition is complete, use 1mol / L sodium hydroxide solution to adjust the pH value of the system to always be about 10 during the whole dropping process, then raise the temperature to 75°C, keep the temperature constant for 9h, wash, filter, and vacuum dry for 30 hours to obtain surface modification LDHs.

[0039] Add 5 parts of surface organically modified LDHs to chlorobenzene, and ultrasonically disperse for 60 minutes to obtain a stable dispersion with a concentration of 15 g / L; then add the obtained dispersion to a tetrahydrofuran solution in which 100 parts of PVC are completely dissolved, and tet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com