Preparation method and application of compound PVC (polyvinyl chloride) antistatic agent

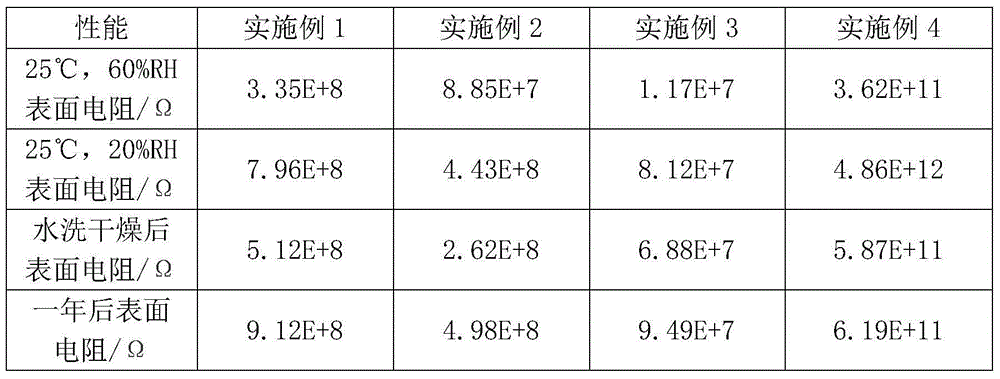

A technology of antistatic agent and catalyst, which is applied in the field of preparation of compound PVC antistatic agent, can solve the problems of product surface yellowing and failure to meet requirements, achieve antistatic effect improvement, price advantage, and solve the problem of poor heat resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

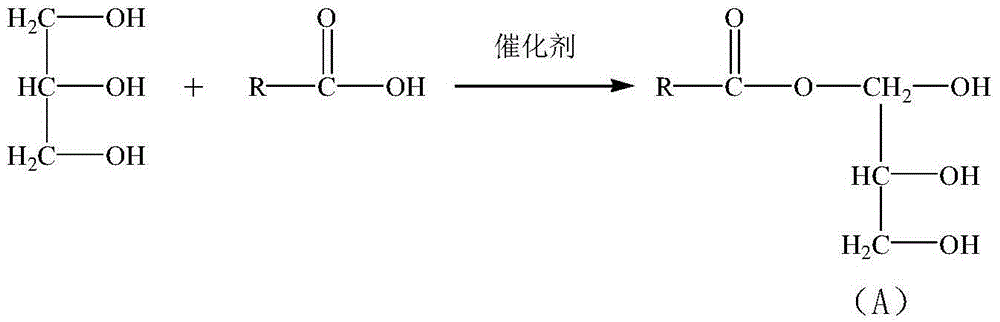

Method used

Image

Examples

Embodiment 1

[0031] (1) Reacting 1 mol of glycerin and 1 mol of fatty acid under the catalysis of sulfuric acid at 110°C for 1 hour to generate fatty acid glyceride (A);

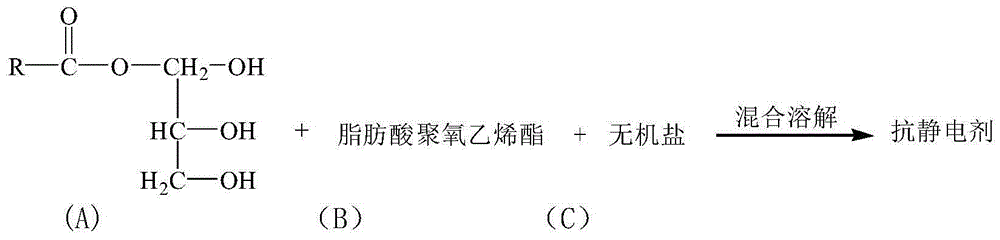

[0032] (2) Cool the prepared fatty acid monoglyceride to 80°C, add polyoxyethylene fatty acid ester, and continue to cool down, until the temperature drops to 50°C, add inorganic metal salt, and continue to stir for 1 hour to fully dissolve it, and obtain Composite PVC antistatic agent.

[0033] Wherein, by weight percentage, the content of each component is: fatty acid monoglyceride (A) 50%, fatty acid polyoxyethylene ester (B) 30%, inorganic metal salt (C) 20%.

Embodiment 2

[0035] (1) Reacting 1.5 mol of glycerol and 1 mol of fatty acid under the catalysis of phosphoric acid at 160°C for 6 hours to generate fatty acid glyceride (A);

[0036] (2) Cool the prepared fatty acid monoglyceride to 130°C, add polyoxyethylene fatty acid ester, and continue to cool down, until the temperature drops to 100°C, add inorganic metal salt, and continue stirring for 5 hours to fully dissolve it, and obtain Composite PVC antistatic agent.

[0037] Wherein, by weight percentage, the content of each component is: fatty acid monoglyceride (A) 80%, fatty acid polyoxyethylene ester (B) 10%, inorganic metal salt (C) 10%.

Embodiment 3

[0039] (1) Reacting 1.1 mol of glycerol and 1 mol of fatty acid under the catalysis of hypophosphorous acid at 120°C for 2 hours to generate fatty acid glyceride (A);

[0040] (2) Cool the prepared fatty acid monoglyceride to 90°C, add polyoxyethylene fatty acid ester, and continue to cool down, until the temperature drops to 60°C, add inorganic metal salt, and continue to stir for 2 hours to fully dissolve it, and obtain Composite PVC antistatic agent.

[0041] Wherein, by weight percentage, the content of each component is: fatty acid monoglyceride (A) 60%, fatty acid polyoxyethylene ester (B) 20%, inorganic metal salt (C) 20%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com