Special high-glossiness modified master batch for transparent PVC (Polyvinyl Chloride) hard product

A hard product and modification technology, applied in the field of high-gloss modified masterbatch for transparent PVC rigid products, can solve the problem that mechanical properties and light stability are prone to decline, mechanical properties and light stability cannot be further improved, and the transparency of high-gloss masterbatch is not good. Advanced problems, to achieve the effect of improving interfacial compatibility, uniform particle size and morphology, and improving transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

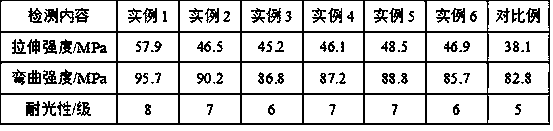

Examples

example 1

[0030] According to the mass ratio of 1:10, the titanate coupling agent and the ethanol solution with a mass fraction of 90% were stirred and mixed, and then nano-titanium dioxide 3.5 times the mass of the titanate coupling agent was added, and then the temperature was 70°C, and the rotation speed was Under the condition of 500r / min, stir and react at a constant temperature for 5h. After the reaction is completed, centrifuge to collect the lower sediment, and wash the lower sediment with deionized water for 6 times, and then transfer the washed lower sediment to an oven. Drying at a temperature of 110°C to a constant weight yields titanate coupling agent-modified nano-titanium dioxide, which is the filler; in parts by weight, 50 parts of graphene oxide, 20 parts of octadecylamine, 120 parts of Parts of trichloromethane were mixed and poured into a three-necked flask. Under the condition of temperature of 95°C and rotation speed of 600r / min, the reaction was stirred at a constan...

example 2

[0032]According to the mass ratio of 1:10, the titanate coupling agent and the ethanol solution with a mass fraction of 90% were stirred and mixed, and then nano-titanium dioxide 3.5 times the mass of the titanate coupling agent was added, and then the temperature was 70°C, and the rotation speed was Under the condition of 500r / min, stir and react at a constant temperature for 5h. After the reaction is completed, centrifuge to collect the lower sediment, and wash the lower sediment with deionized water for 6 times, and then transfer the washed lower sediment to an oven. Drying at a temperature of 110°C to a constant weight yields titanate coupling agent-modified nano-titanium dioxide, which is the filler; in parts by weight, 50 parts of graphene oxide, 20 parts of octadecylamine, 120 parts of Parts of trichloromethane were mixed and poured into a three-necked flask. Under the condition of temperature of 95°C and rotation speed of 600r / min, the reaction was stirred at a constant...

example 3

[0034] In parts by weight, take 50 parts of graphene oxide, 20 parts of octadecylamine, and 120 parts of chloroform in turn, mix them and pour them into a three-necked flask. Stir the reaction for 24 hours, filter to obtain a filter cake, and wash the obtained filter cake with deionized water for 5 times, then transfer the washed filter cake to an oven, and dry it to a constant weight at a temperature of 110°C to obtain modified graphite oxide Pour PVC resin and solvent into a beaker with a mass ratio of 1:6, stir and mix with a glass rod for 20 minutes, let it stand for swelling for 24 hours, and then heat-treat at a temperature of 110°C until the solvent is completely evaporated, and then The material in the beaker is kept at a temperature of 60°C and left to age for 18 hours to obtain the aged material, and then the obtained aged material is frozen with liquid nitrogen for 4 hours, and then pulverized to obtain the pretreated PVC matrix resin; calculated in parts by weight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com