Spill-proof control method of soybean milk maker and soybean milk maker

A control method and technology of soymilk machine, applied in dairy products, beverage preparation devices, milk substitutes, etc., can solve the problems of complex structural design, overcooked and undercooked soymilk, etc., to prevent large differences in effects and reduce overflow prevention devices , cost-saving effect

Active Publication Date: 2013-03-27

MIDEA GRP CO LTD

View PDF6 Cites 35 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] However, the above-mentioned anti-overflow control method needs to install an anti-overflow device, and the anti-overflow device must be arranged on the upper part of the pulp cooking cup, so its structural design is more complicated, and it is very inconvenient to affect the appearance of the product and clean it.

Moreover, since the altitude of the soymilk maker is unknown, it is impossible to predict when the soymilk will overflow, but heating according to a fixed program may cause the soymilk to be overcooked or undercooked.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment approach

[0050] Step a, heating the pulp cooking cup that is equipped with water and material;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

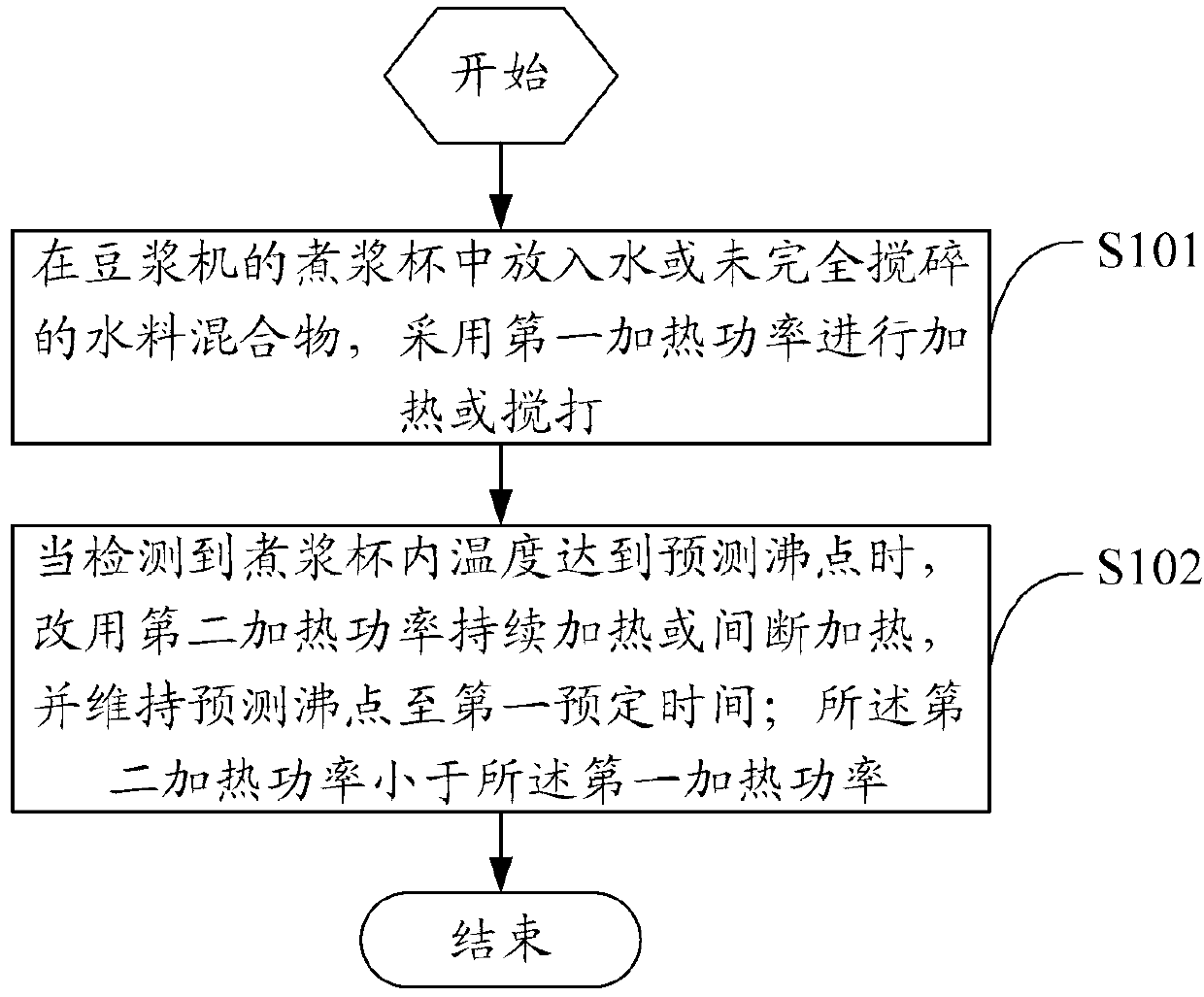

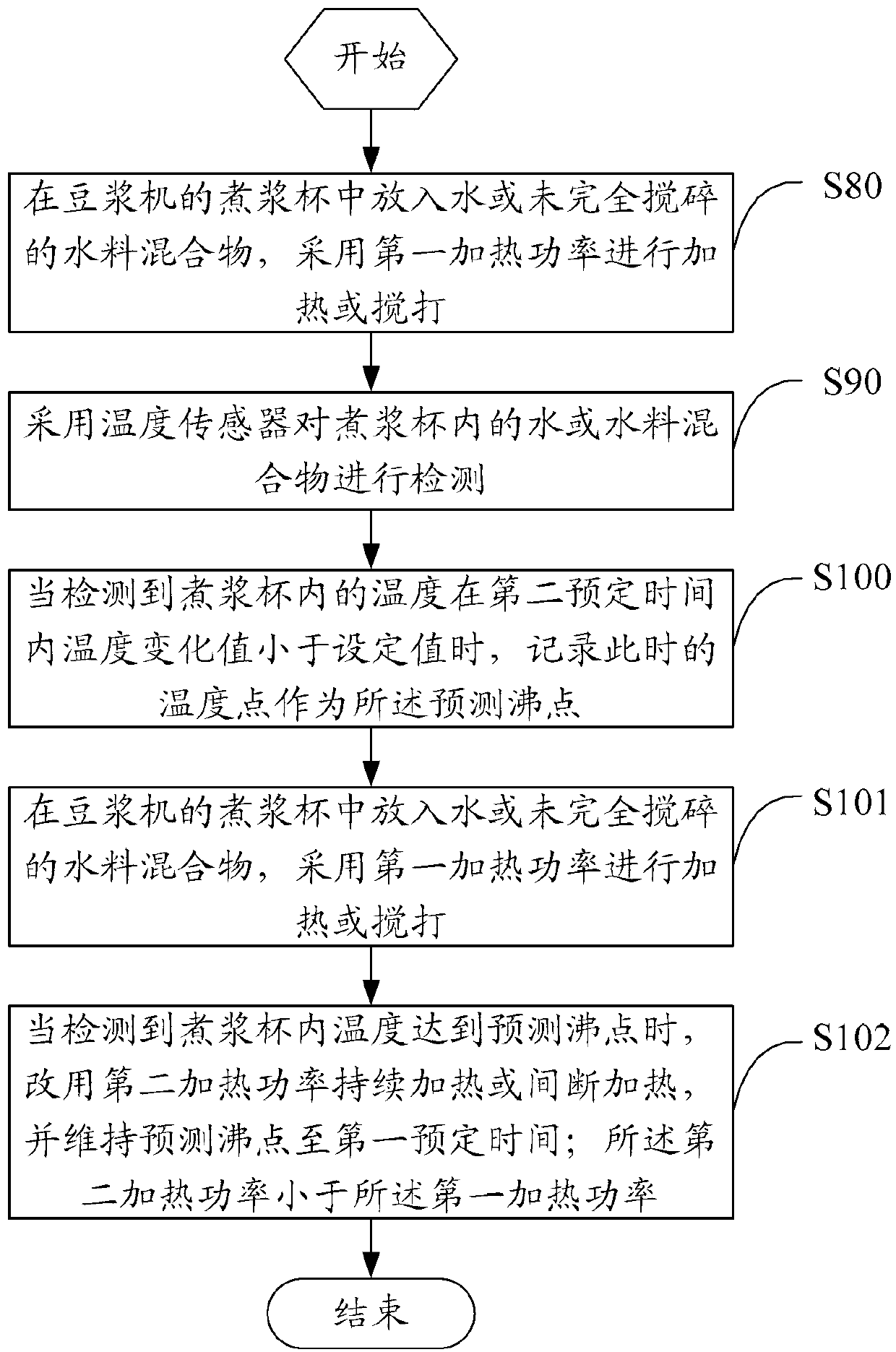

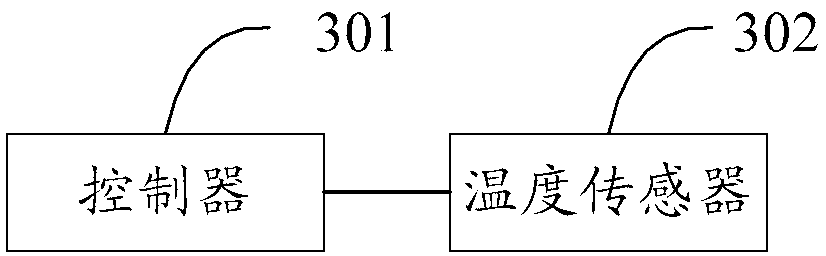

The invention discloses a spill-proof control method of a soybean milk maker and the soybean milk maker. The spill-proof control method comprises the following steps of: putting water or a water-material mixture in a soybean milk cooking cup of the soybean milk maker and heating or stirring by adopting a first heating power; and when detecting that the temperature in the soybean milk cooking cup reaches a predicted boiling point, continuously heating or intermittently heating by adopting a second heating power and maintaining the predicted boiling point for a first preset time, wherein the second heating power is lower than the first heating power. According to the invention, a temperature sensor is used for acquiring data and judging the current boiling point through analysis and calculation according to the temperature data, so that soybean milk can be cooked thoroughly by taking the current boiling point as a parameter standard for subsequent program control, and no spillage phenomenon can be caused. According to the spill-proof control method disclosed by the invention, the capabilities of saving a spill-proof device of the traditional soybean milk maker, simplifying the structure, saving the cost and solving the problem of large effect difference of soybean milk caused by different elevations in different places can be realized.

Description

technical field [0001] The invention relates to the technical field of household electrical appliances, in particular to a soymilk maker overflow prevention control method and the soymilk maker. Background technique [0002] Usually when the soymilk machine is cooking milk, when it reaches a certain temperature, the soymilk will overflow. [0003] In order to solve the anti-overflow problem, the existing soymilk machine is generally equipped with an anti-overflow device in the cooking cup of the soymilk machine. When the anti-overflow device detects an overflow signal, reduce the heating power of the cooking cup or stop heating until the soymilk recovers. When it reaches the normal liquid level, continue heating or continue heating with low power. [0004] But above-mentioned this anti-overflow control mode, owing to need to install anti-overflow device, and anti-overflow device must be arranged on the top of pulp cooking cup, so its structural design is more complicated, a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A47J31/56A47J31/00A47J43/04A23C11/10

Inventor 杨伸其尹坤任

Owner MIDEA GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com