Waste polypropylene-modified foaming plate and manufacturing method thereof

A waste polypropylene and foamed sheet technology, applied in chemical instruments and methods, flat products, other household appliances, etc., can solve the problems of difficult recycling, increased product brittleness, and high product cost, and achieves a simple and easy addition method. , The effect of improving melt strength and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

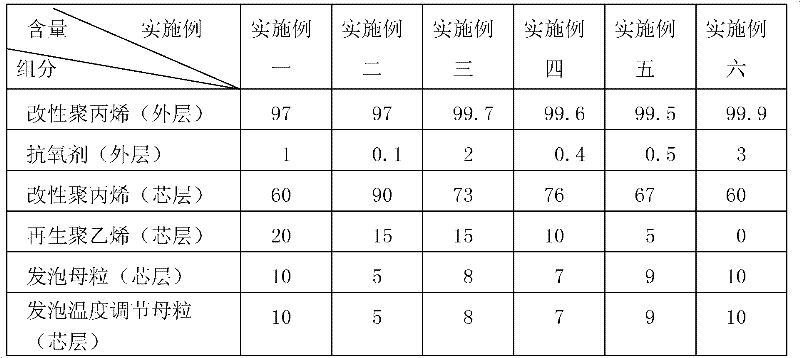

[0046] A waste polypropylene modified foam board, which consists of a core foam layer and an outer layer covering the upper and lower surfaces of the core foam layer, the outer layer is made by mixing and melting the following components, each group The content of points is calculated in parts by weight as:

[0047] 97 parts of modified polypropylene, 1 part of antioxidant;

[0048] The foaming layer of the core layer is made by mixing, melting and foaming the following components, and the content of each component is calculated in parts by weight:

[0049] 60 parts of modified polypropylene, 20 parts of recycled polyethylene, 10 parts of foaming masterbatch, and 10 parts of foaming temperature regulating masterbatch.

[0050] In this example:

[0051] ①. The foam masterbatch is a masterbatch made of activated inorganic powder as a carrier, mixed with a foaming agent, and coated with low-density polyethylene. The content of each component of the foam masterbatch is expressed...

Embodiment 2 Embodiment 6

[0064] A waste polypropylene modified foam board, which consists of a core foam layer and an outer layer covering the upper and lower surfaces of the core foam layer, the outer layer is made by mixing and melting the following components, each group The content of parts is calculated in parts by weight as

[0065] 97-99.9 parts of modified polypropylene, 0.1-3 parts of antioxidant;

[0066] The foaming layer of the core layer is made by mixing, melting and foaming the following components, and the content of each component is calculated in parts by weight:

[0067] 60-90 parts of modified polypropylene, 0-20 parts of recycled polyethylene, 5-10 parts of foaming masterbatch, 5-10 parts of foaming temperature-adjusting masterbatch. (See attached table 1 for the content of the above components)

[0068] For each embodiment of above-mentioned embodiment two to embodiment six:

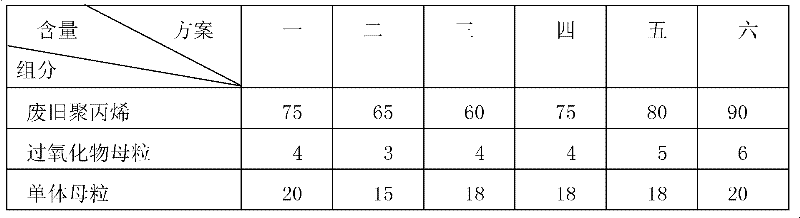

[0069] ①. The foam masterbatch is a masterbatch made of activated inorganic powder as a carrier, mixe...

Embodiment 7

[0092] Embodiment 7: A kind of manufacturing method of waste and old polypropylene modified foam board, comprises the following steps:

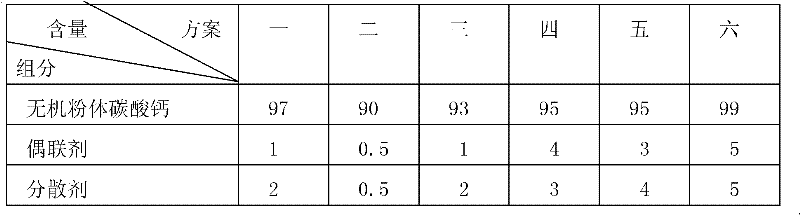

[0093] ①. Production of activated inorganic powder: take 90-99 parts of inorganic powder, 0.5-5 parts of coupling agent, and 0.5-5 parts of dispersant, and put the above-mentioned inorganic powder, coupling agent and dispersant in a mixer Stir to 90-100°C and take out of the pan to obtain activated inorganic powder.

[0094] ②. Making peroxide masterbatch of modification additive: Take 45-80 parts of activated inorganic powder, 1-5 parts of peroxide, and 20-30 parts of thermoplastic elastomer, and put the thermoplastic elastomer into the internal mixer , heated and stirred to a molten state, cooled to below 140°C; put the activated inorganic powder in a blender and stirred to 60-70°C, poured in the peroxide and stirred for 1-5 minutes, then mixed the peroxide with The mixture of activated inorganic powders is gradually poured into the intern...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com