Tunneling type graphite boat for semi-conducting material liquid phase epitaxial growth

A graphite boat and graphite pad technology, which is applied in liquid phase epitaxial layer growth, crystal growth, chemical instruments and methods, etc., can solve the problems affecting the growth of high-quality epitaxial films, and the difficulty in guaranteeing the verticality and flatness of grooves, and achieves a reduction in the Residue, the effect of improving quality and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing and embodiment the specific embodiment of the present invention is described in further detail:

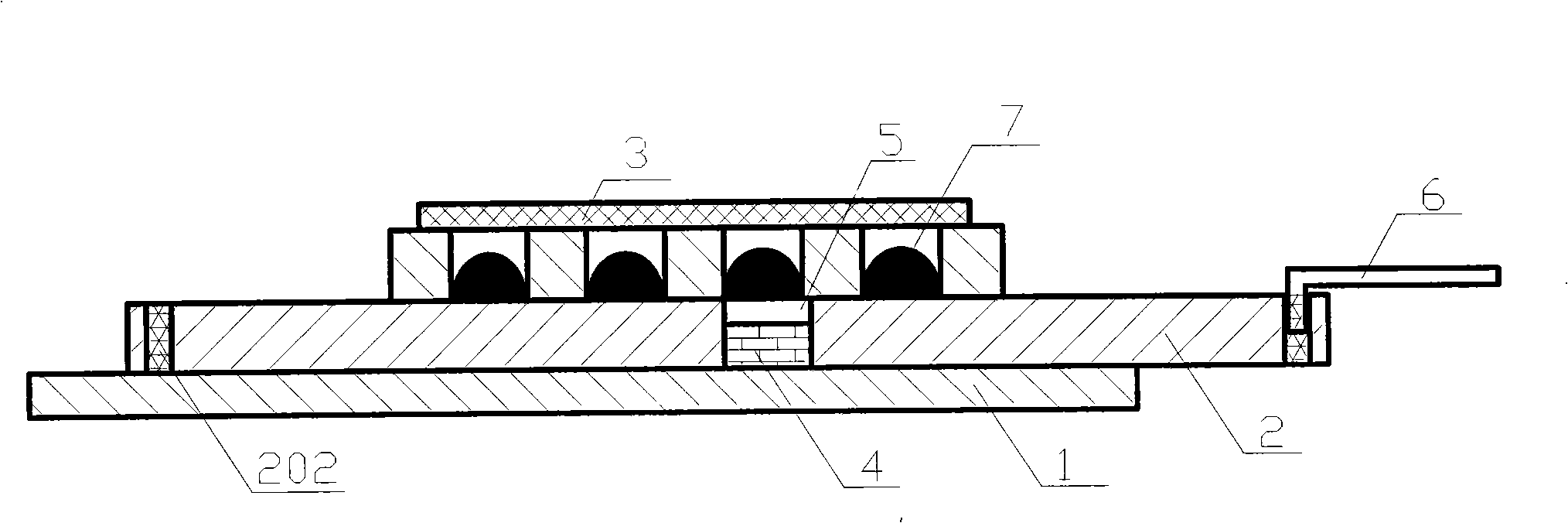

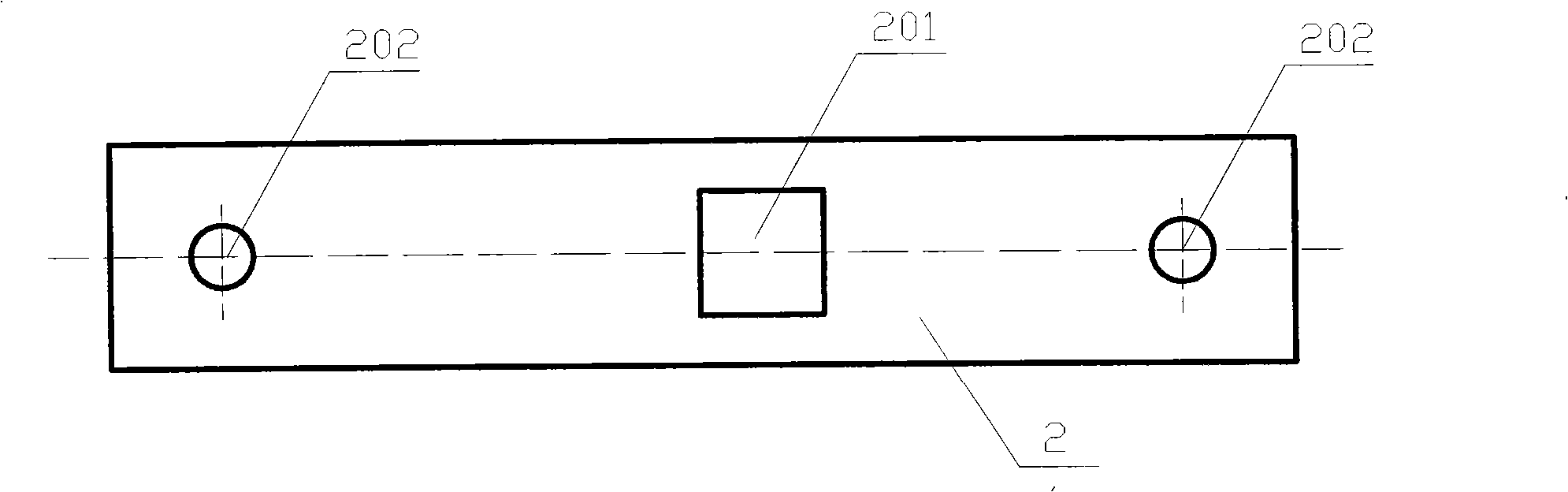

[0010] The graphite boat includes: a boat body 1 with a tunnel, a slider 2 matching the cross-sectional size of the tunnel, a cover plate 3 and a graphite gasket 4.

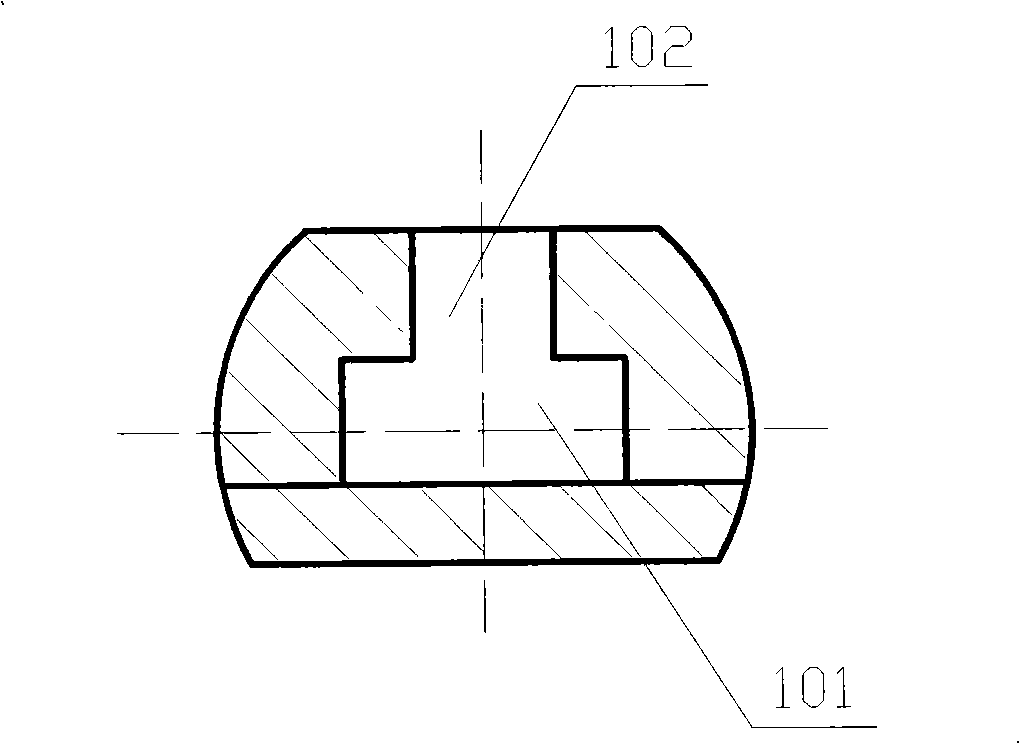

[0011] The boat body 1 adopts a section of cylindrical graphite to truncate the upper and lower arcs, which looks like a drum shape from the cross section. This design is mainly to increase the mechanical strength of the graphite boat. A rectangular tunnel 101 is opened in the boat body 1, and the top surface of the tunnel is provided with four equally spaced mother liquor square holes 102 for placing mother liquor 7 of different components. These four mother liquor square holes 102 are required to be at exactly the same distance during processing, and the error is - within 0.05mm.

[0012] A substrate square hole 201 of the same size as the epitaxial substrate 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com