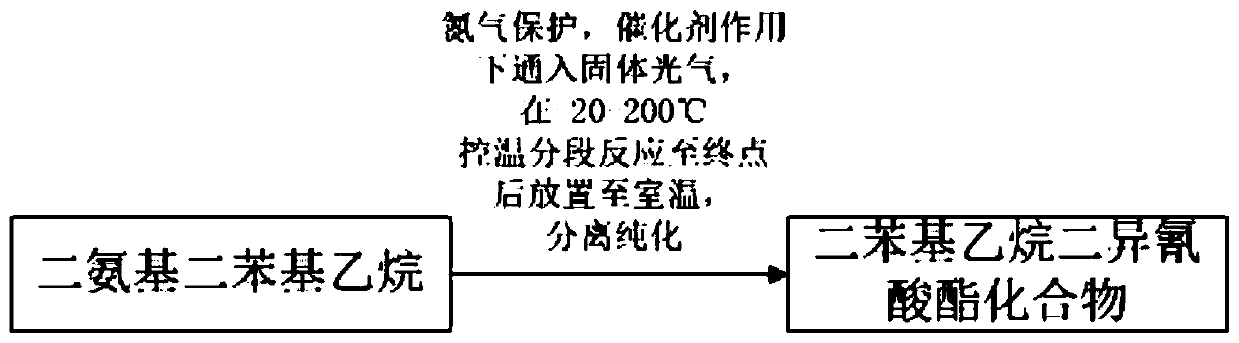

Diphenylethane diisocyanate prepared by a solid phosgene method and application thereof

A technology of diphenylethane diisocyanate and diaminodiphenylethane, which is applied in the field of polymer material monomer preparation, can solve the problems of strong corrosiveness of by-product hydrochloric acid, affecting product application performance, and difficulty in removing residual chlorine. , to achieve the effect of strong reaction stability, safe use, improved quality and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

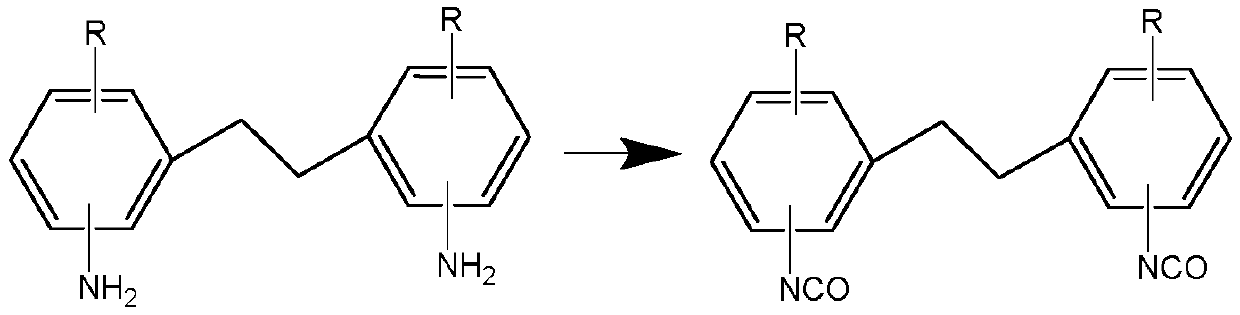

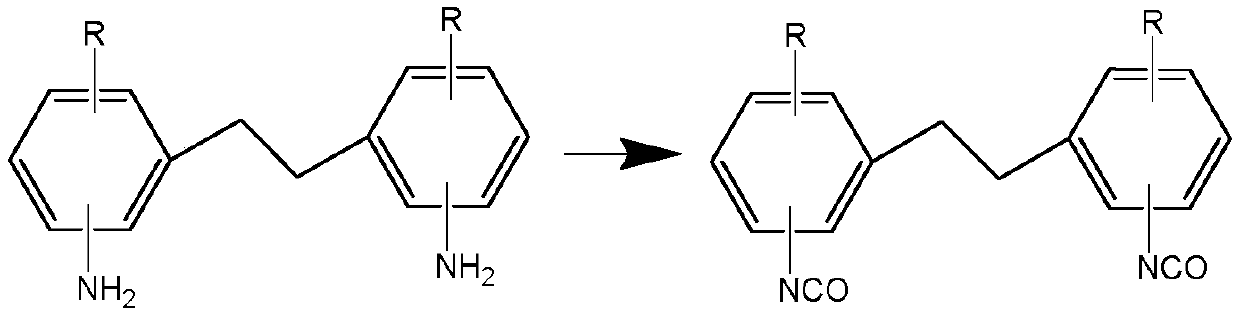

[0042] Add 20.0L of chloroform to the reaction kettle, add 2.12kg of 4,4'-diaminodiphenylethane and stir to dissolve, then add 1.0L of DMF, freeze to -20℃, add 2.17kg of solid phosgene while stirring, maintain- After reacting at 20°C to 0°C for 1 hour, heat to reflux for 2-12 hours,

[0043] Developing agent: petroleum ether-ethyl acetate (1:1), color developing agent: 5% phosphomolybdic acid ethanol solution, TLC detects all the reaction of 4,4'-diaminodiphenylethane, the white is obtained after removing the solvent The powdered product is 2.55kg. The purity of the product detected by HPLC normalization method was 97.5%, 13 C NMR(100MHz, CDCl 3 )δ139.32,139.32,130.80,130.80,130.28,130.28,130.28,130.28,127.71,127.71,125.10,125.10,125.10,125.10,37.41,34.42; FAB-HRMS: M / e(264.2762), molecular formula: C 16 H 12 O 2 N 2 , Which is diphenylethane-4,4'-diisocyanate (EDI-a1).

[0044] According to the method similar to Example 4, selecting suitable starting materials 5,5'-diaminodipheny...

Embodiment 2

[0046] Add 30.0L of dichloromethane into the reaction kettle, add 2.40kg of 2,2'-dimethyl-4,4'-diaminodiphenylethane and stir to dissolve, then add 1.0L of DMF, and freeze to -20℃. Add 2.20kg of solid phosgene while stirring, keep at -20℃ to 0℃ for 1 hour, then heat and reflux for 2-12 hours.

[0047] Developing reagent: petroleum ether-ethyl acetate (1:1), developer: 5% phosphomolybdic acid ethanol solution, TLC detection 2,2'-dimethyl-4,4'-diaminodiphenylethane For the entire reaction, nitrogen gas was bubbled, hydrogen chloride was removed in vacuum for 0.5 h, and the solvent was removed to obtain 2.80 kg of white powder. The purity of the product detected by HPLC normalization method was 97.0%, 13 C NMR(100MHz, CDCl 3 )δ136.74,136.74,134.41,134.41,130.70,130.70,130.13,130.13,127.71,127.71,126.50,126.50,122.02,122.02,35.39,35.39,19.10,19.10; FAB-HRMS: M / e(292.3300), Molecular formula: C 18 H 16 O 2 N 2 , Which is 2,2'-dimethyl-diphenylethane-4,4'-diisocyanate (EDI-b1).

Embodiment 3

[0049] Add 10.0L DMF to the reactor, add 2.40kg of 2,2'-dimethyl-5,5'-diaminodiphenylethane, stir to dissolve, freeze to -20℃, add 2.95kg of solid phosgene while stirring After reacting at -20°C to 0°C for 1 hour, heat to 150°C and continue to react for 2-12 hours.

[0050] Developing reagent: petroleum ether-ethyl acetate (1:1), developer: 5% phosphomolybdic acid ethanol solution, TLC detection 2,2'-dimethyl-5,5'-diaminodiphenylethane For the entire reaction, nitrogen gas was bubbled, hydrogen chloride was removed in vacuum for 0.5 h, and the solvent was removed to obtain 2.75 kg of white powder. The purity of the product detected by HPLC normalization method was 98.0%, 13 C NMR(100MHz, CDCl 3 )δ138.30,138.30,132.71,132.71,130.47,130.47,128.82,128.82,127.40,127.40,125.29,125.29,122.21,122.21,36.39,36.39,19.08,19.08; FAB-HRMS: M / e(292.3298), Molecular formula: C 18 H 16 O 2 N 2 , Which is 2,2'-dimethyl-diphenylethane-5,5'-diisocyanate (EDI-b2).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com