Hydrotreatment-catalytic cracking combination process method

A catalytic cracking and hydrotreating technology, applied in hydrotreating process, hydrocarbon oil treatment, petroleum industry, etc., can solve the problem of high sulfur content in catalytic gasoline, improve quality and yield, reduce SOx content and product quality excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

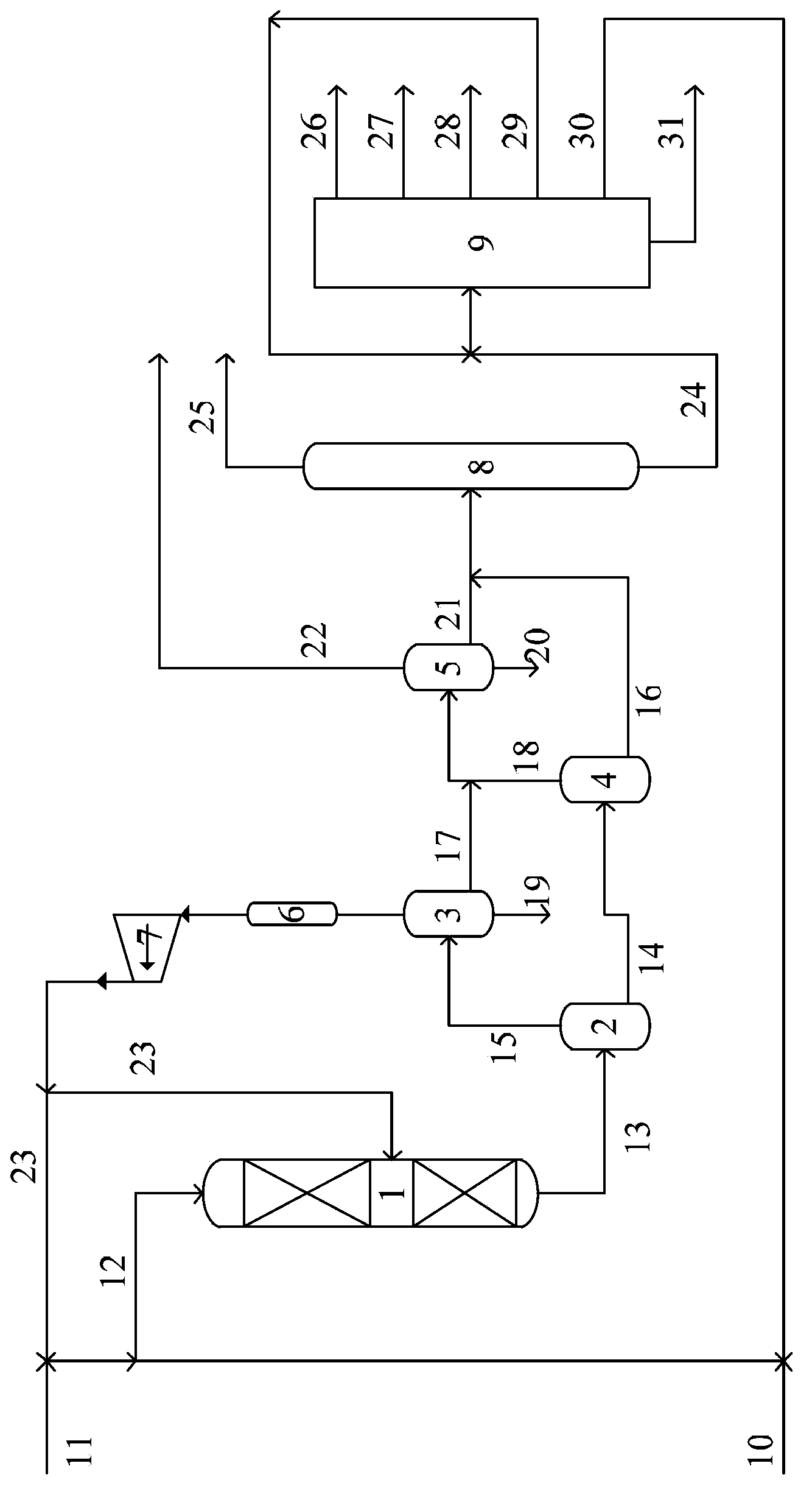

Method used

Image

Examples

Embodiment 1

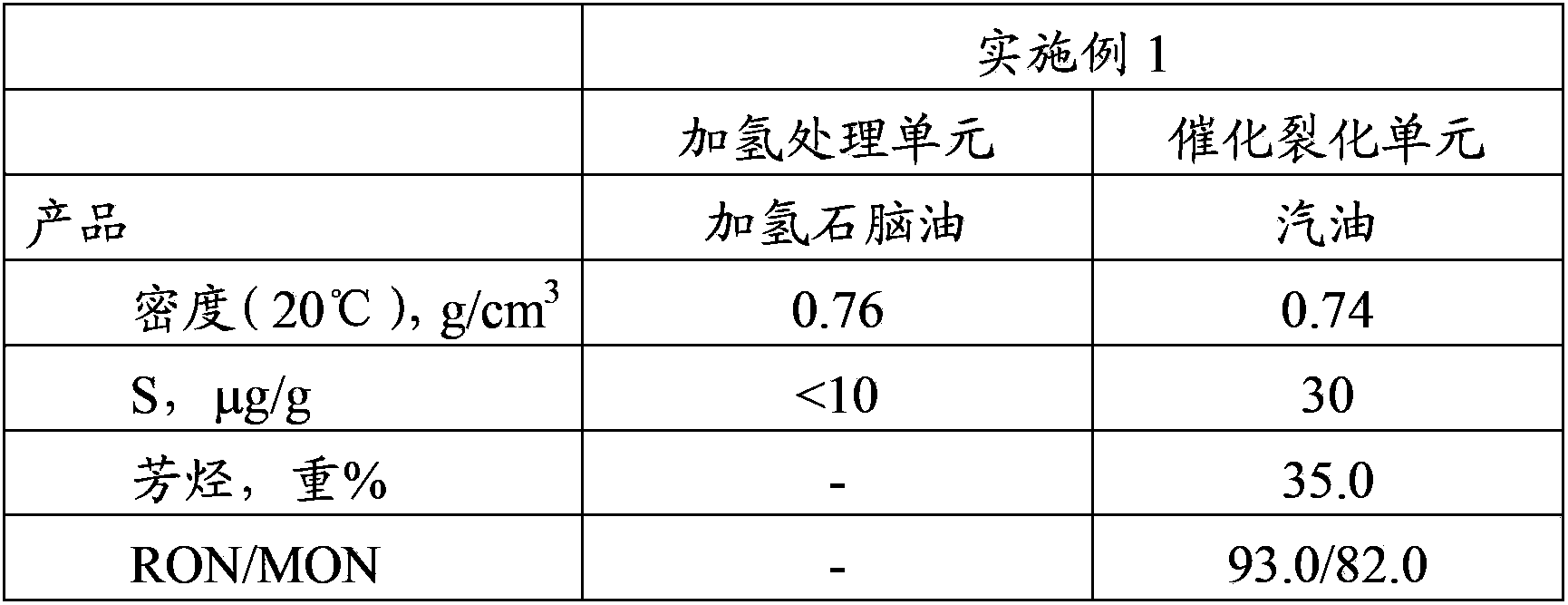

[0038] The wax oil raw material G and the catalytic cycle oil are mixed and then enter the hydrotreating reaction zone, and successively contact and react with the hydroprotecting agent A, hydrogen protecting agent B, hydrodesulfurizing agent C and hydrotreating catalyst E. The loading volume of the above catalysts The ratio is 4:4:20:72. By adopting the process flow shown in the accompanying drawing, the obtained hydrogenated tail oil is a fraction greater than 165°C. The distillation range of the obtained catalytic light oil is 190°C-270°C, the content of single-ring aromatics is 51% by mass, and it is self-circulated back to the catalytic cracking unit. The distillation range of the catalytic cycle oil is 270°C to 460°C fraction, the content of aromatic hydrocarbons above double rings is 69% by mass, and the catalytic cycle oil is returned to the hydrotreating reaction zone.

[0039] Table 2, Table 3 and Table 4 are the process parameters, product distribution and product ...

Embodiment 2

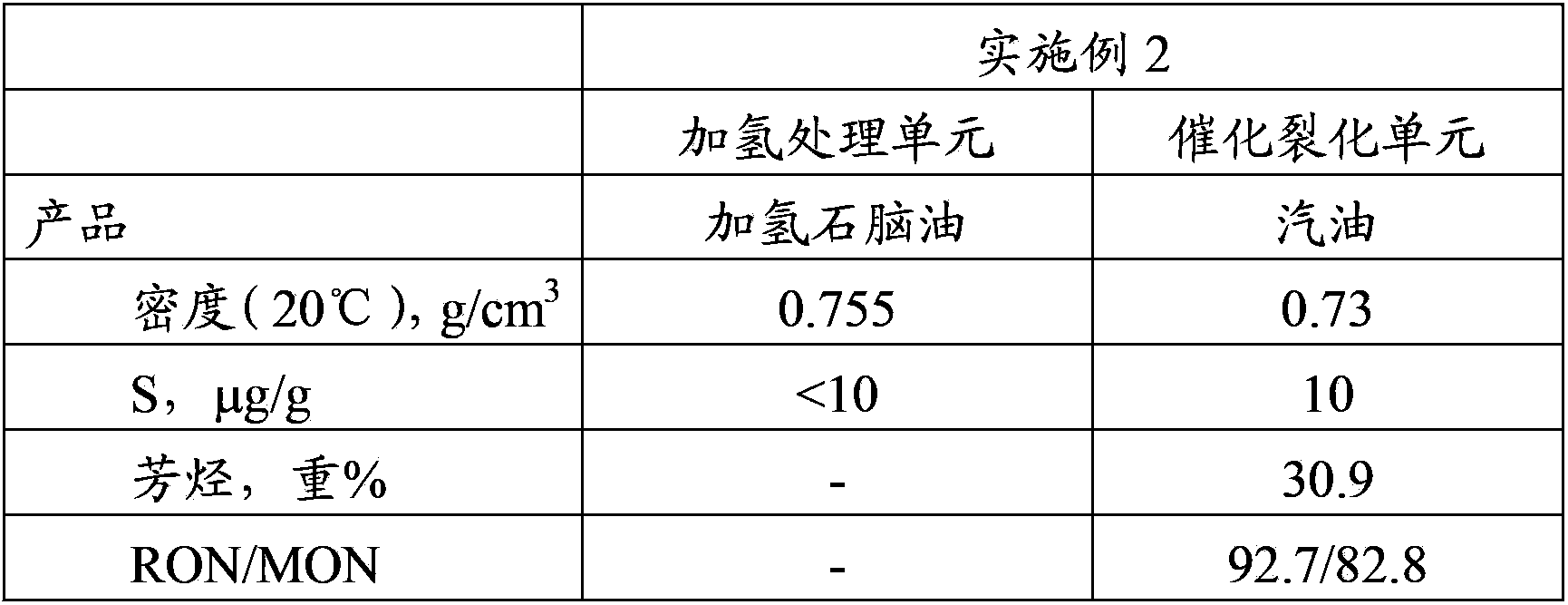

[0041] The wax oil raw material H and the catalytic cycle oil are mixed and then enter the hydrotreating reaction zone, and successively contact and react with the hydrogenation protecting agent A, the hydrogenation protecting agent B, the hydrodemetallization agent D and the hydrotreating catalyst E, and the loading of the above catalysts The volume ratio is 5:5:15:75. By adopting the process flow shown in the accompanying drawing, the obtained hydrogenated tail oil is a fraction greater than 165°C. The distillation range of the obtained catalytic light diesel oil is 190°C-255°C, the content of single-ring aromatics is 62% by mass, and it is self-circulated back to the catalytic cracking unit. The distillation range of the catalytic cycle oil is 255°C-460°C fraction, the content of aromatic hydrocarbons above double rings is 65% by mass, and the catalytic cycle oil is returned to the hydrotreating reaction zone.

[0042] Table 2, Table 3 and Table 5 are the process parameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com