Equipment and method for manufacturing liquid crystal optical element

A technology of liquid crystal optics and manufacturing equipment, applied in optics, nonlinear optics, instruments, etc., can solve problems such as restricting industrial upgrading, unfavorable development of liquid crystal optical components, and difficulty in achieving alignment effect by rubbing method, and achieves elimination of dust and static electricity. The effect of improving yield and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

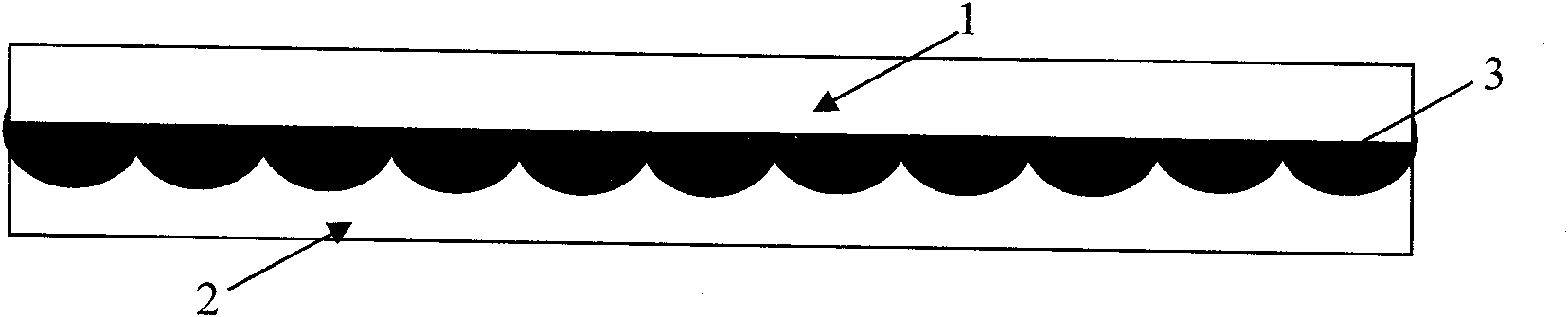

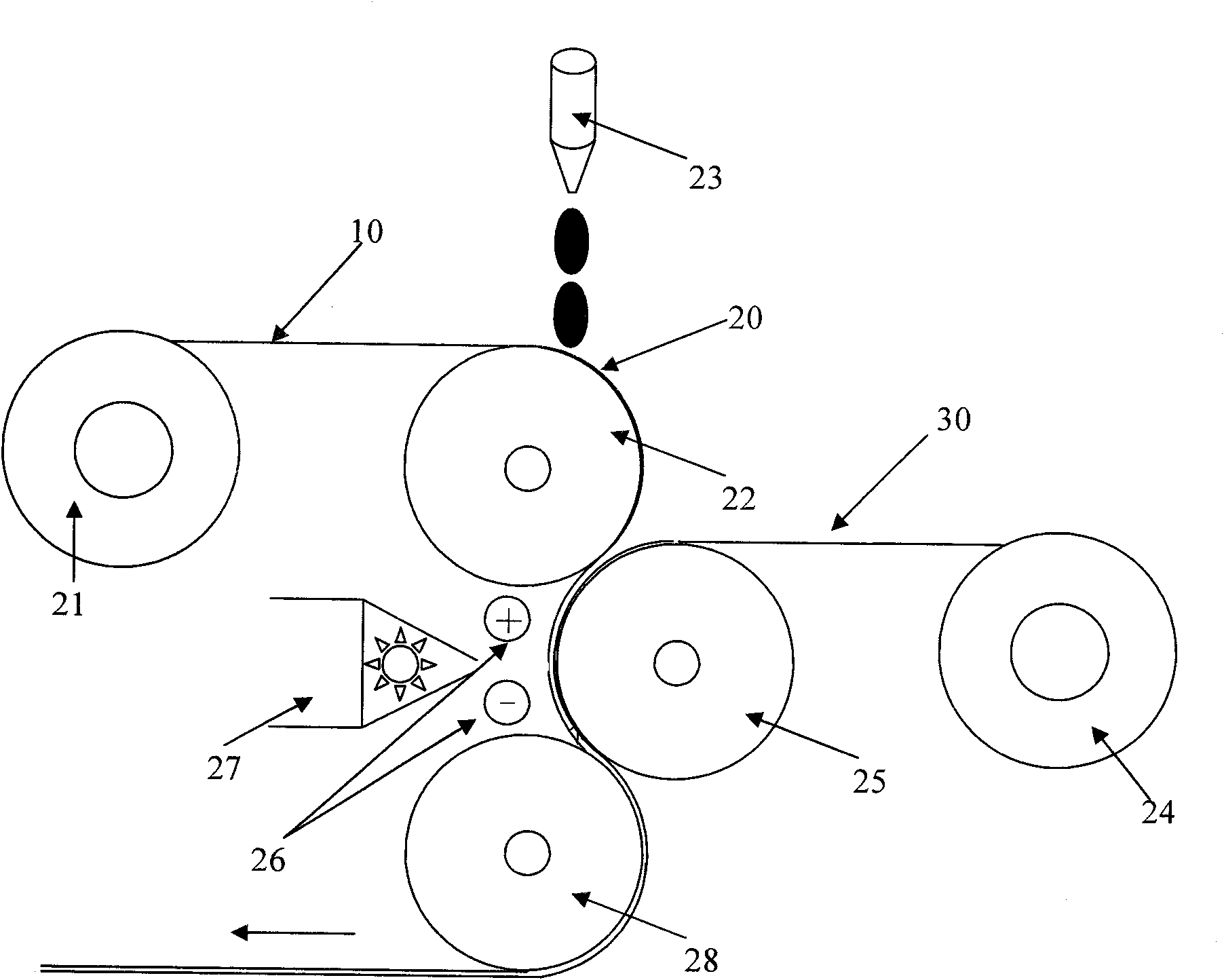

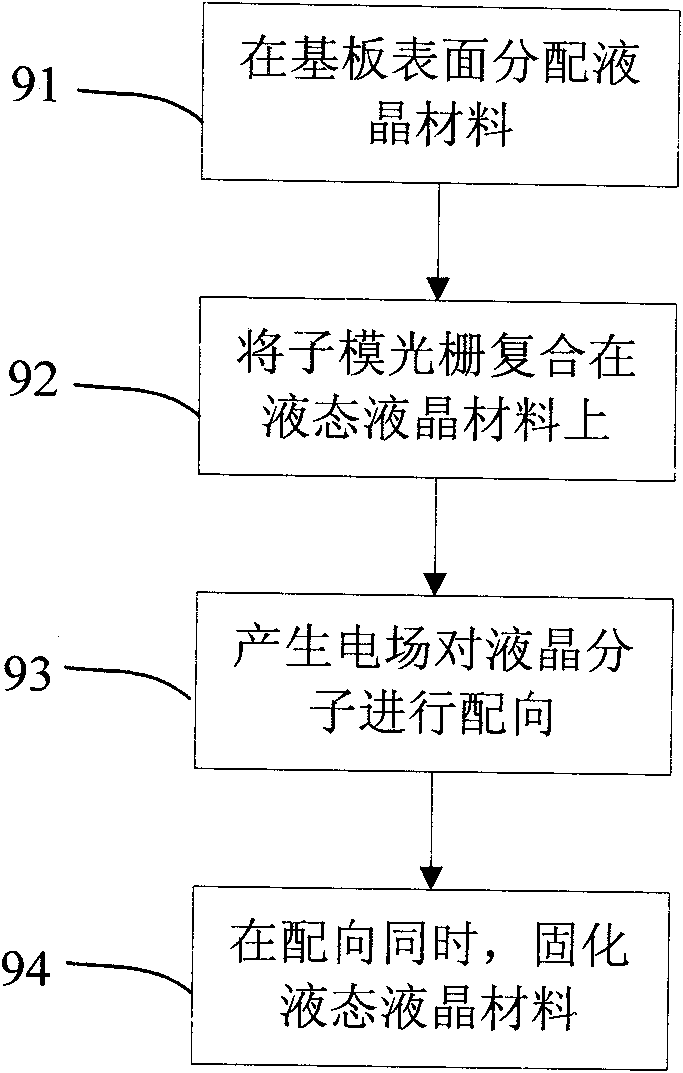

[0026] Such as figure 2 As shown, the present invention provides a manufacturing equipment of a liquid crystal optical element. This manufacturing facility can be used to manufacture figure 1 The liquid crystal birefringent grating is shown. The manufacturing equipment mainly includes a first delivery roller 21, a first transfer roller 22, a liquid crystal distribution device 23, a second delivery roller 24, a second delivery roller 25, an electric field generating device 26, a curing device 27 and a first Three transfer rollers 28 .

[0027] In operation, the substrate 10 placed in the first sending roller 21 is conveyed by the first conveying roller 22 . In this embodiment, the substrate 10 is a PET substrate, and is placed in the first delivery roller 21 in rolls. The liquid crystal dispensing device 23 dispenses the liquid crystal material 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com