Injection mold automatic thread twisting device

An injection mold, automatic technology, applied in the field of automatic twisting device of injection mold, can solve the problems of long molding cycle, high quality defect rate, easily damaged products, etc., achieve structural safety, high quality yield rate, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

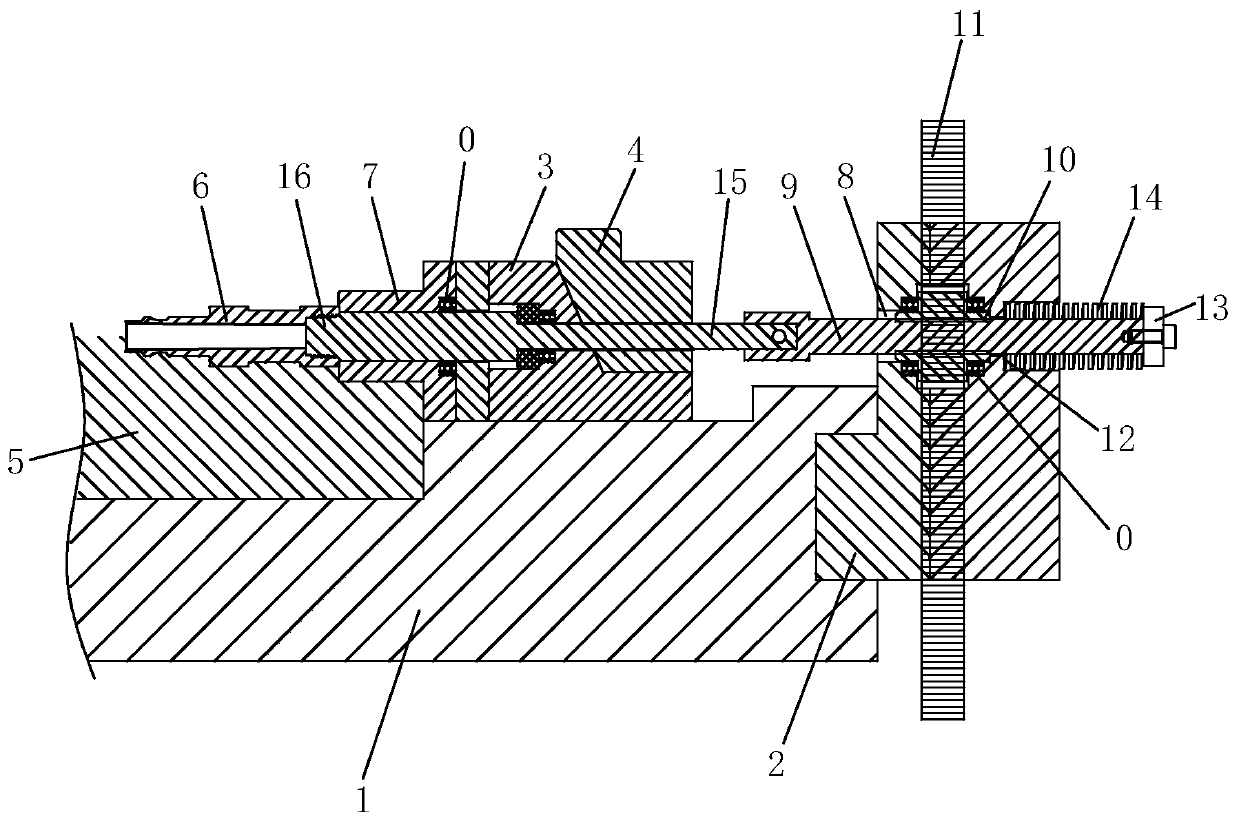

[0013] Such as figure 1 As shown, the automatic twisting device of the injection mold of the present invention comprises a template 1, one end of the template 1 presses the front template 2, the upper end of the template 1 is a slider seat 3, the rear end of the slider seat 3 bears on the slider 4, and the template 1 is matched With a moving model cavity 5, there is molding product 6 in the moving model cavity 5, and the slide block seat 3 cooperates with the moving model cavity 5 by a slide block insert 7.

[0014] Such as figure 1 As shown, a cavity 8 is provided in the front template 2, and a connecting rod 9 is embedded in the front template 2, and the connecting rod 9 passes through the cavity 8. The connecting rod 9 fixes a gear 10 in the front template 2, and the gear 10 is arranged on In the cavity 8, the gear 10 cooperates with the front template 2 through the bearing 0. Fit a rack 11 on the gear 10, the rack 11 is also embedded in the front template 2, and the rack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com