Method for reducing sulfur content of catalytically cracked gasoline

A technology for catalytically cracking gasoline and catalytic cracking units, which is applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating processes, etc., can solve the problems of limited reduction of olefin content and increased energy consumption of the unit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

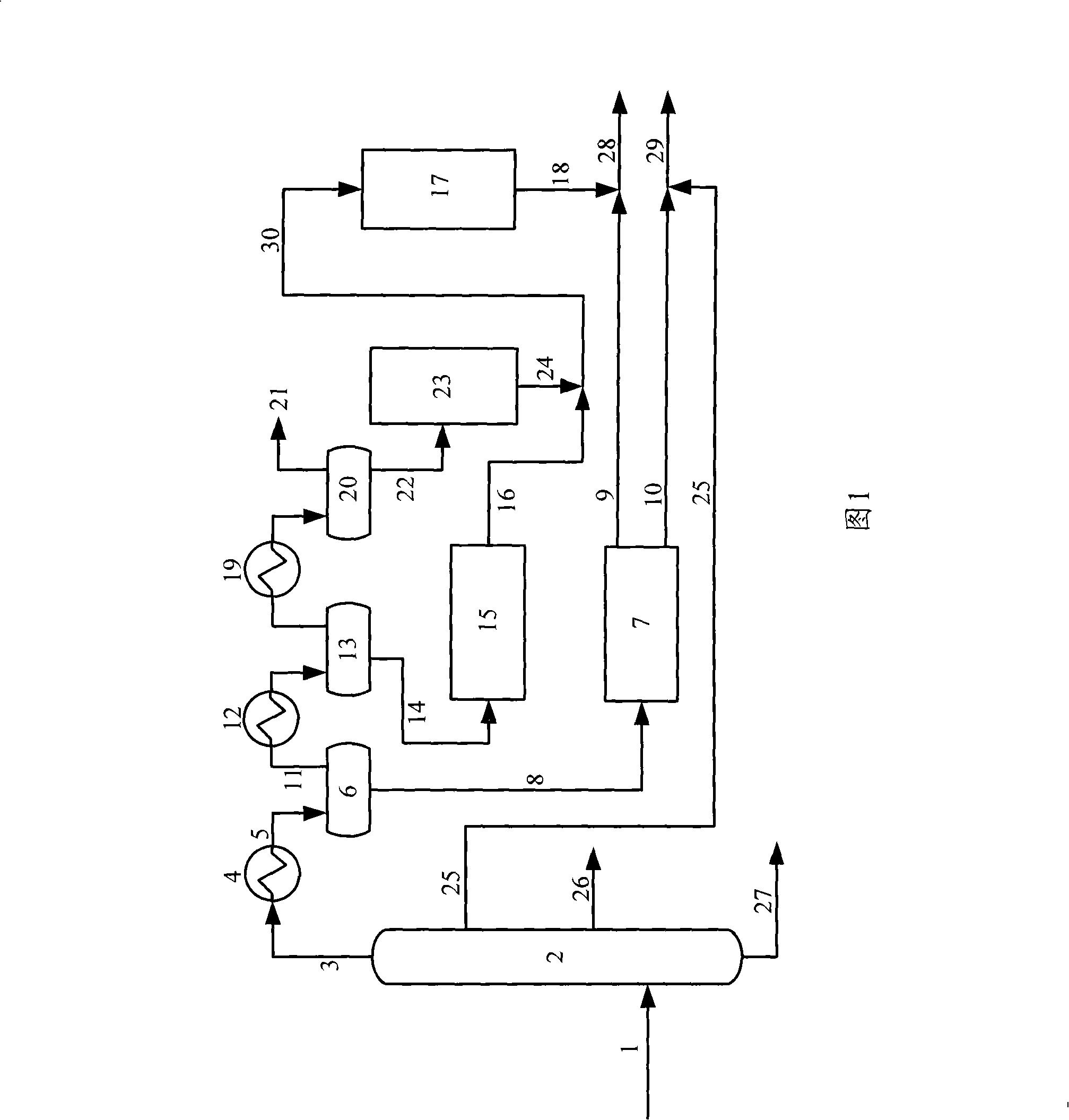

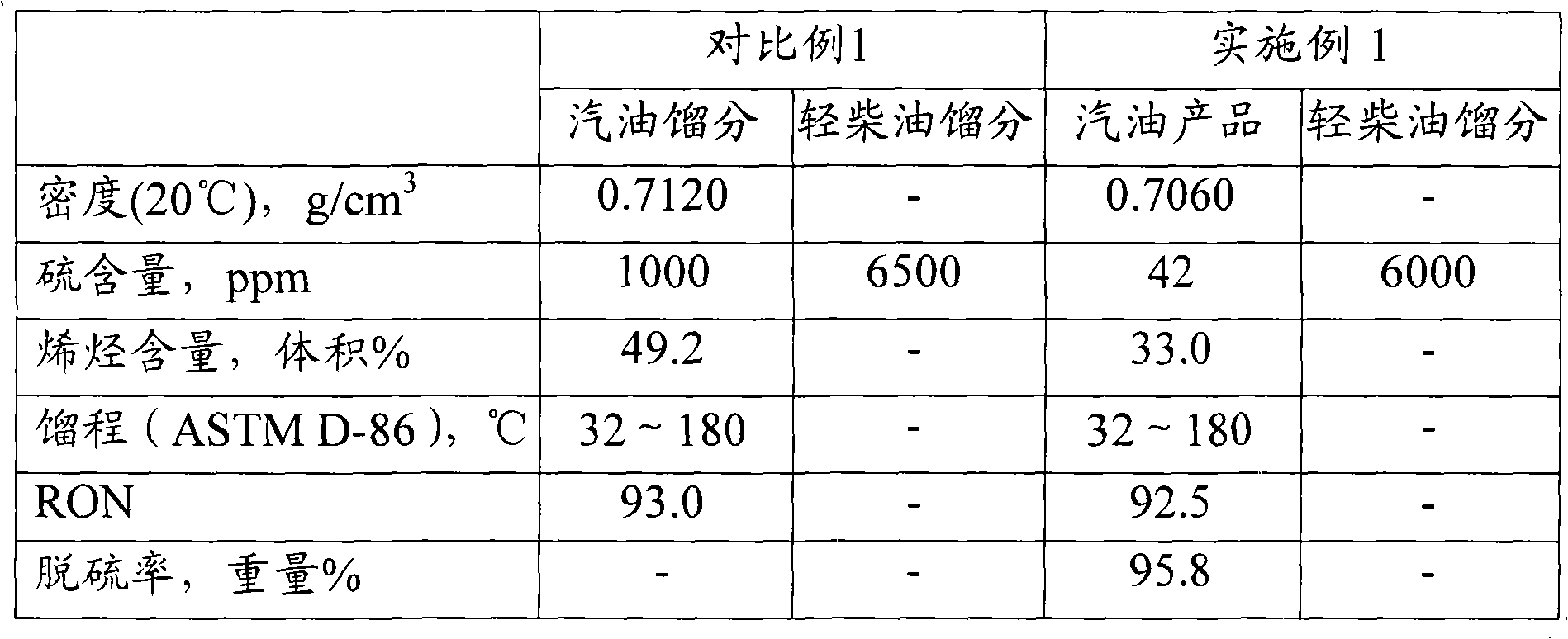

[0056] This embodiment adopts the technical scheme 1 of the present invention, and the raw materials and reaction conditions used in the catalytic cracking unit are the same as those of Comparative Example 1, and the fraction of catalytic cracking reaction oil gas <250 ° C is fractionated into three fractions through graded cooling, wherein the light gasoline fraction is <65°C fraction; medium gasoline fraction is 65-120°C fraction; heavy gasoline fraction is 120-250°C fraction.

[0057] The light gasoline fraction is absorbed by the catalytic cracking absorption stabilization system and then enters the alkali washing deodorization device for deodorization. The medium gasoline fraction enters the first hydrogenation reaction zone and reacts with the hydrogenation catalyst RSDS-1. The hydrogenated medium gasoline fraction enters the alkali washing deodorization device for deodorization treatment. The medium gasoline fraction and its hydrogenation product properties and the first...

Embodiment 2

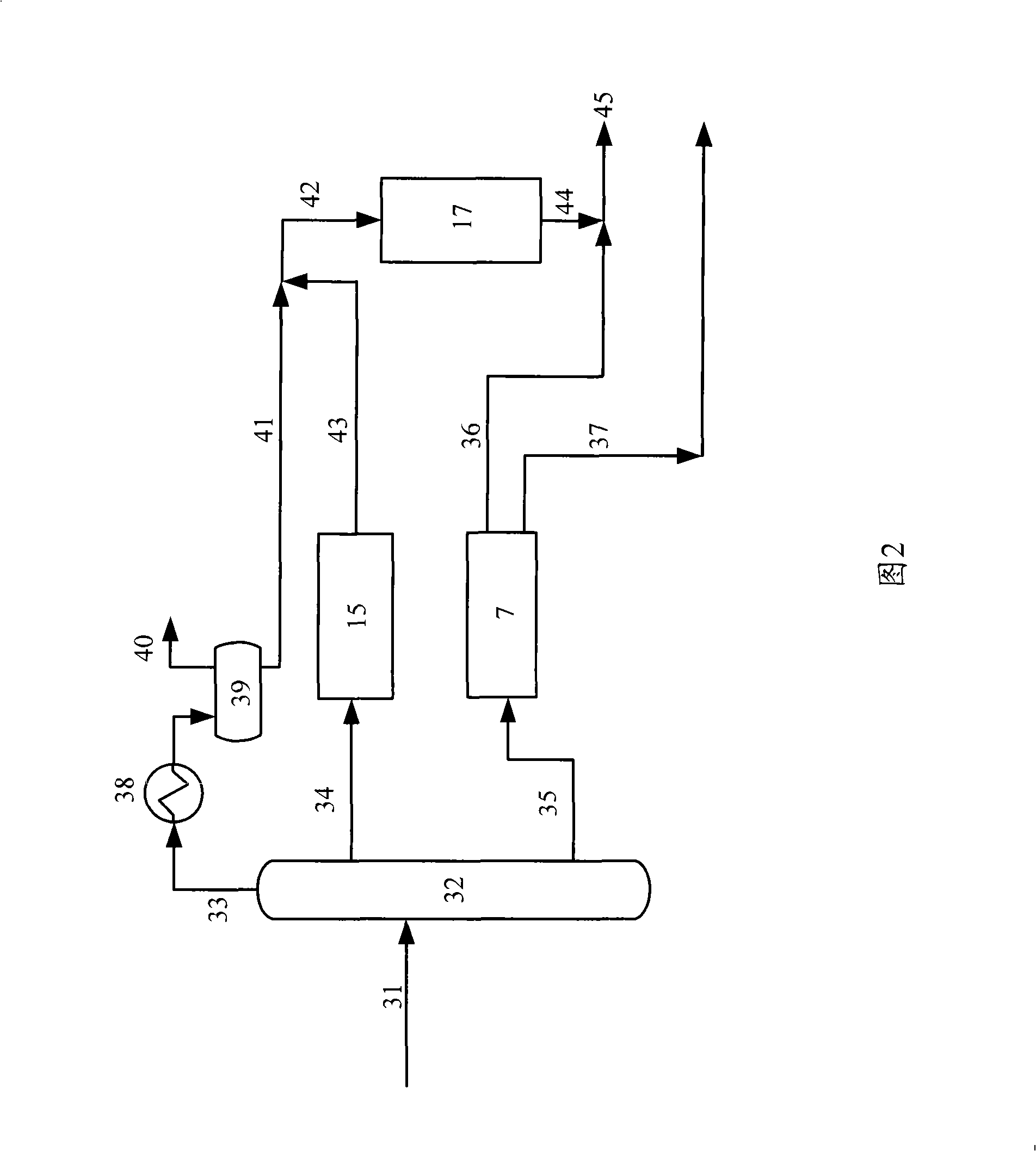

[0062] This embodiment adopts the technical scheme 2 of the present invention, and the raw materials and reaction conditions used in the catalytic cracking unit are the same as those of Comparative Example 2, and the fraction <250°C at the top of the catalytic cracking main fractionation tower is fractionated into three strands through the stabilizing tower of the absorption stabilizing system Fractions, of which the light gasoline fraction is the fraction <80°C; the medium gasoline fraction is the fraction of 80-120°C; the heavy gasoline fraction is the fraction of 120-250°C.

[0063] The light gasoline fraction enters the alkali washing deodorization device for deodorization. The medium gasoline fraction enters the first hydrogenation reaction zone and reacts with the hydrogenation catalyst RSDS-1. The hydrogenated medium gasoline fraction enters the alkali washing deodorization device for deodorization treatment. The medium gasoline fraction and its hydrogenation product pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com