Catalytic conversion method for processing high-nitrogen raw material

A catalytic conversion method and high-nitrogen raw material technology, which is applied in the field of catalytic cracking for processing high-nitrogen hydrocarbon oil raw materials, can solve the problems of reducing gasoline yield, pollution, and reducing raw material conversion rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

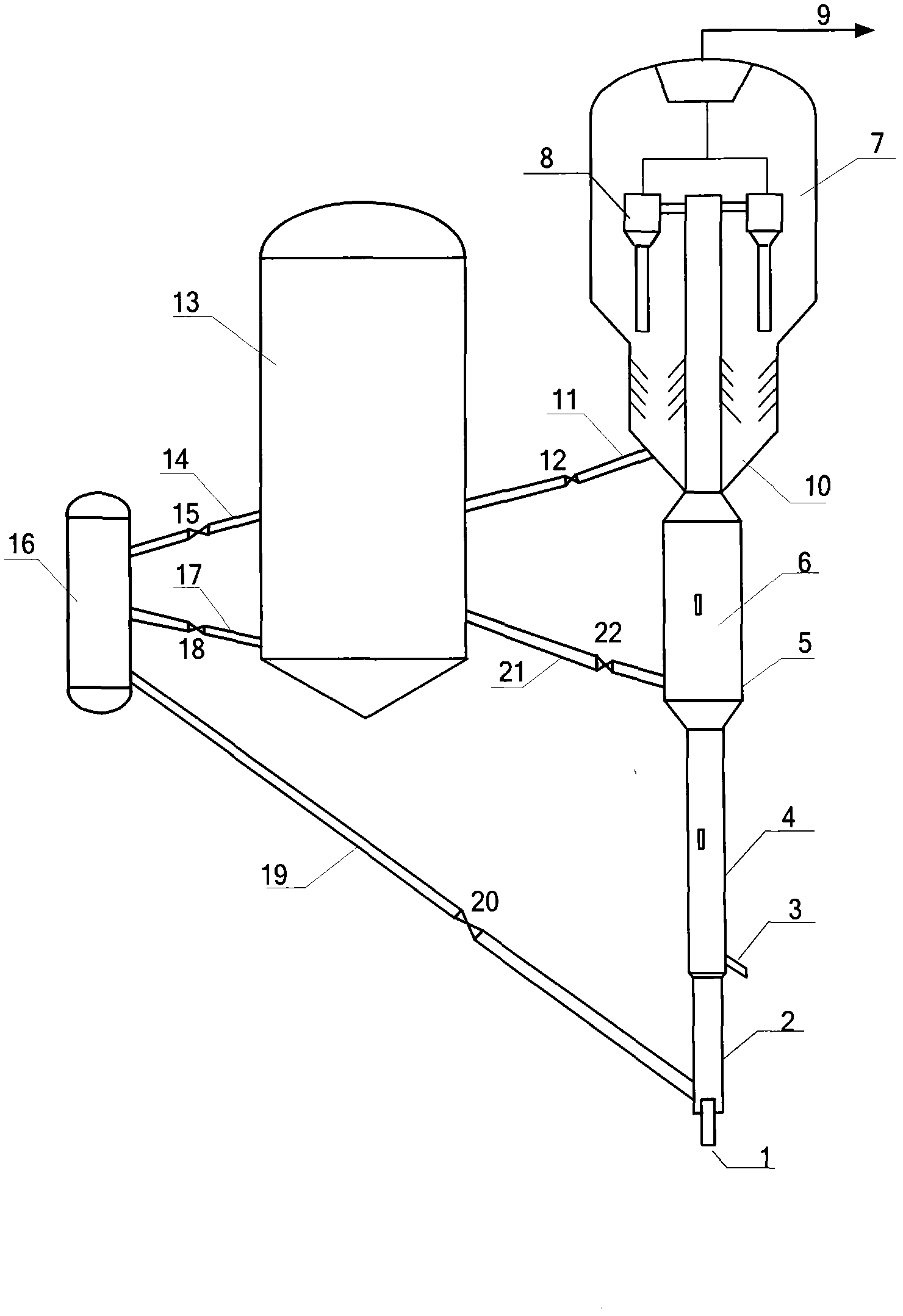

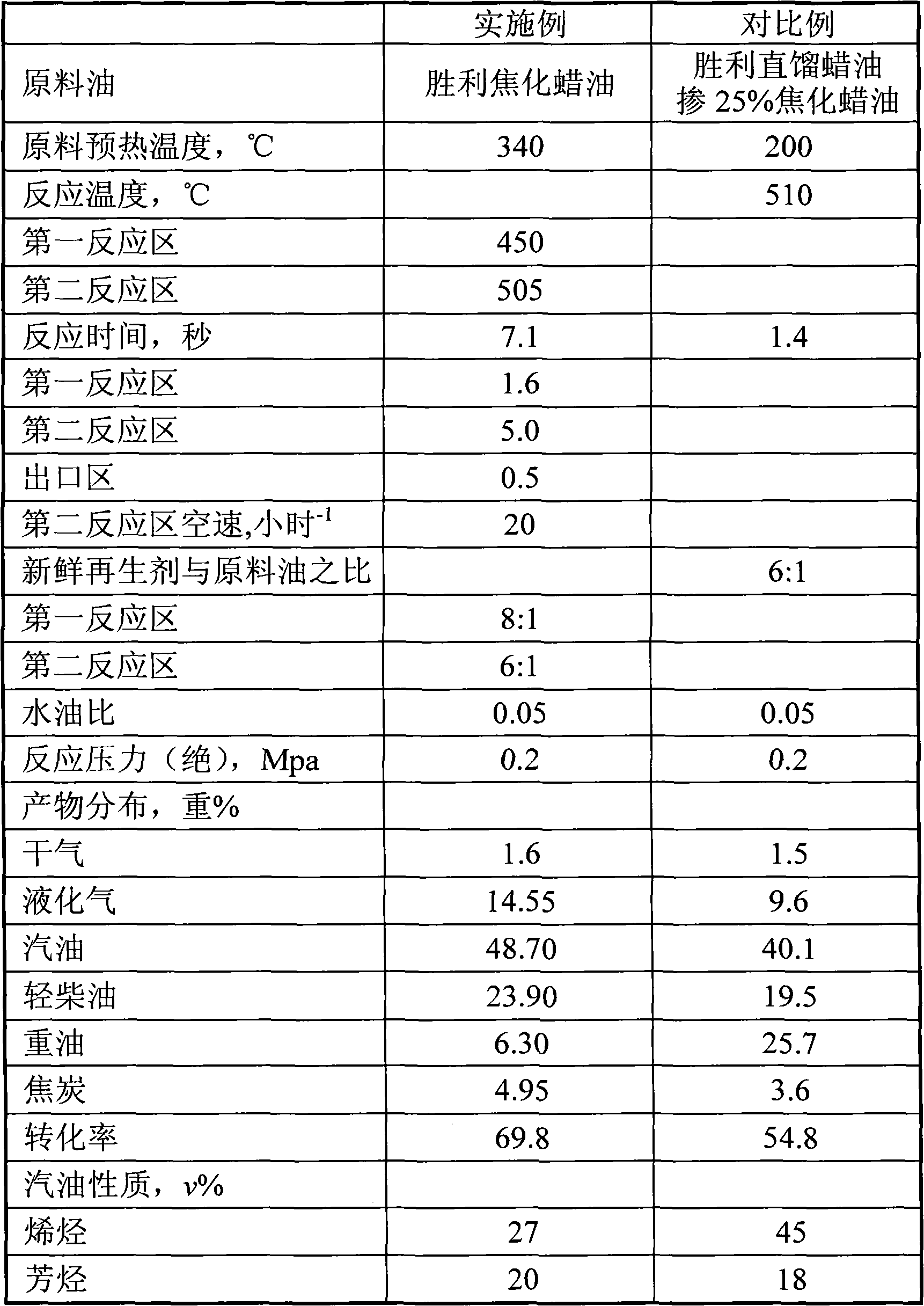

[0036] This example illustrates the situation of directly processing high-nitrogen raw materials using the method provided by the invention.

[0037] The flow chart of the medium-sized catalytic cracking unit is shown in the attached figure. A new type of variable-diameter riser reactor is adopted. The high-nitrogen feed oil (Shengli coker wax oil) is preheated to 340°C and injected into the first reaction of the variable-diameter riser reactor through pipeline 3. The lower part of the first reaction zone contacts and reacts with the low-temperature regenerated catalyst lifted by water vapor. In the first reaction zone, the weight ratio of the catalyst to the high-nitrogen feedstock oil is 8:1, the residence time of the high-nitrogen feedstock gas oil in the first reaction zone is 1.6 seconds, and the temperature in the first reaction zone is 450°C. The oil mixture continues to go up into the second reaction zone, where it contacts and reacts with the high-temperature regenera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com