Catalytic conversion method for hydrocarbon oil raw material

A catalytic conversion method and catalytic cracking technology are applied in the field of catalytic cracking process and can solve the problems of high octane number, low olefin content and high olefin content in gasoline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

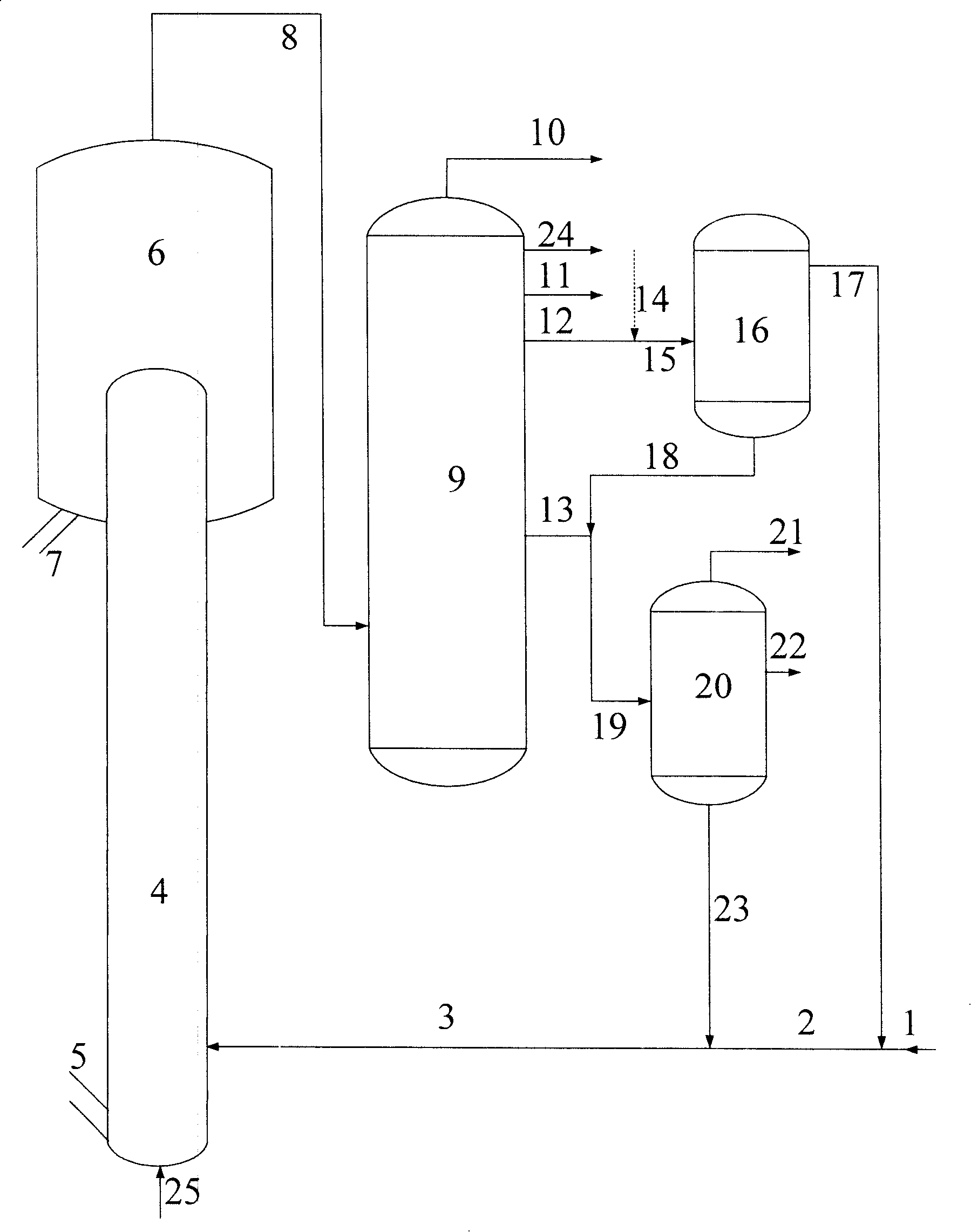

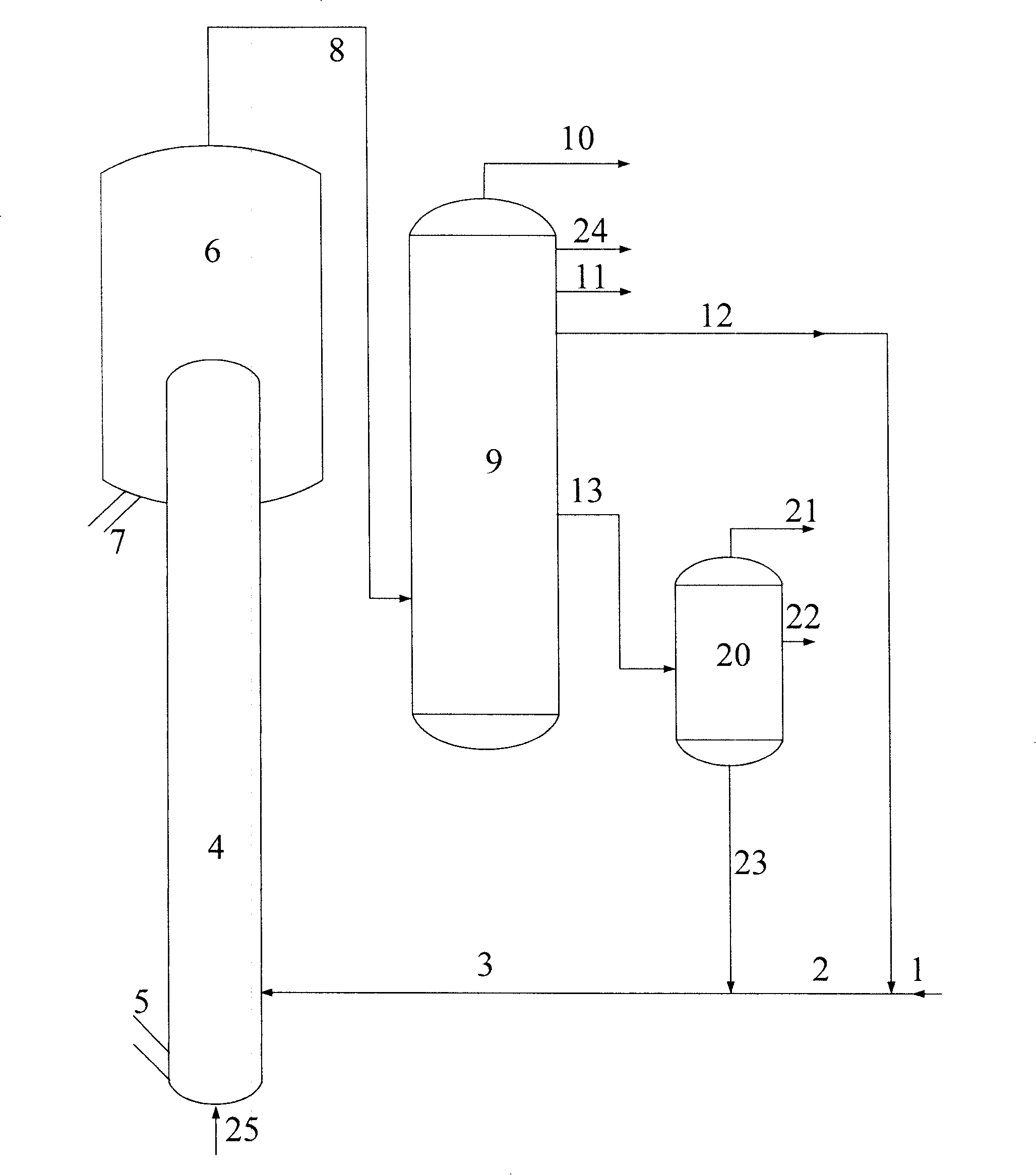

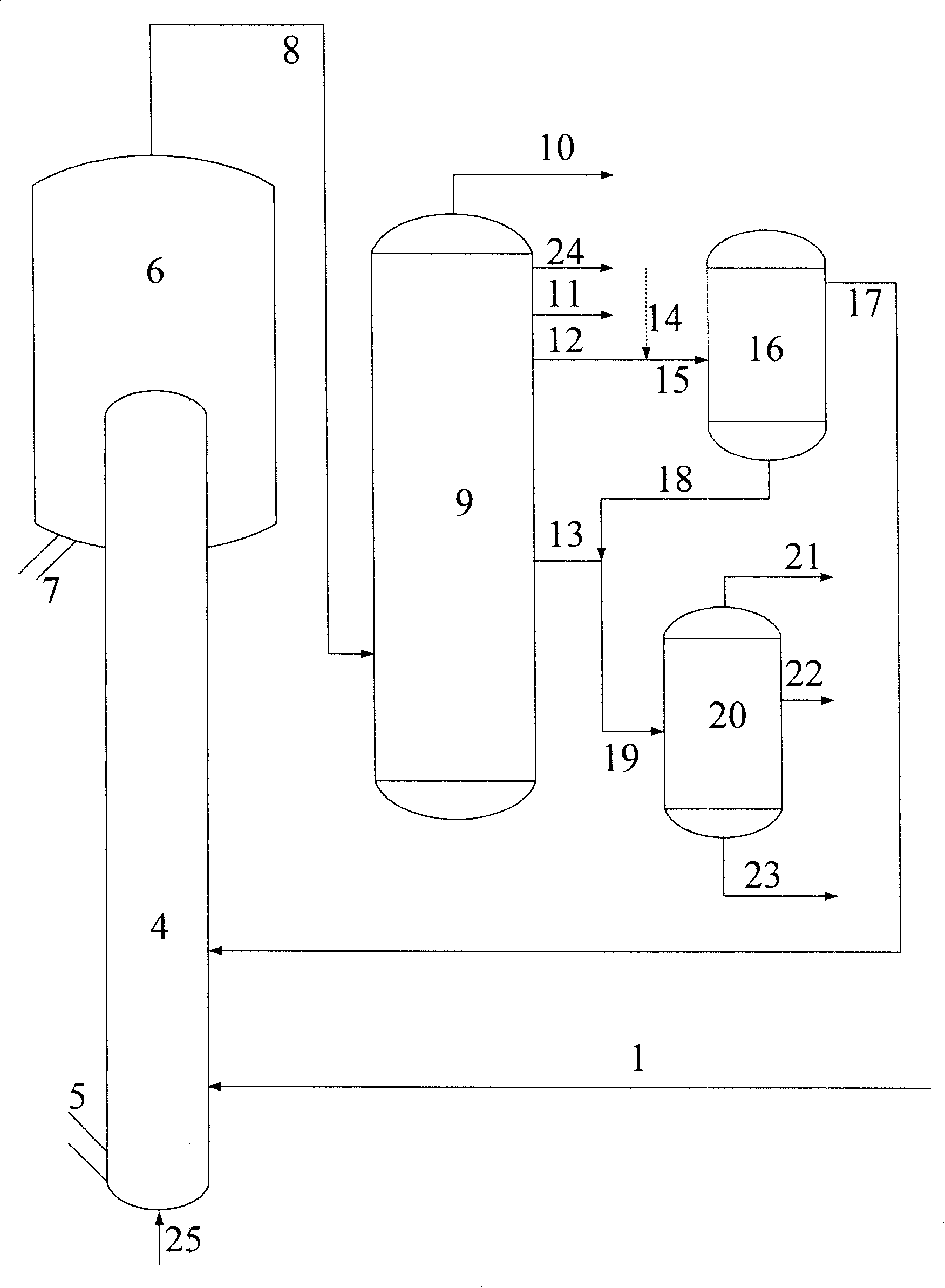

Image

Examples

Embodiment 1

[0064] Refining of light fractions of light cycle oil

[0065] Atmospheric pressure residue enters the reactor and contacts with FCC catalyst MLC-500, at 500°C, agent-to-oil ratio 8, space velocity 8 hours -1 Cracking under certain conditions, fractionation after catalytic cracking to obtain dry gas, liquefied gas, gasoline, light cycle oil, heavy cycle oil, heavy oil, wherein the light cycle oil is cut into light fractions of light cycle oil at 275°C (i.e. <275 ℃ fraction, its partial properties are shown in Table 2) and the heavy fraction of light cycle oil, and then the light fraction of part of light cycle oil (accounting for 15% by weight of the atmospheric residue) is returned to the catalytic cracking reactor and carried out together with the atmospheric residue cracking reaction. The product distribution and gasoline product properties are shown in Table 3 and Table 4, respectively.

Embodiment 2

[0071] The heavy fraction of light cycle oil is mixed with heavy cycle oil for hydrogenation.

[0072] Mix the heavy fraction of the light cycle oil obtained in Example 1 with the heavy cycle oil fraction, contact with hydrogen and hydrogenation catalyst RN-10, at a temperature of 350°C, and a liquid hourly space velocity of 1.5 hours -1 , hydrogen-to-oil ratio (that is, the volume ratio between hydrogen and hydrogenation feedstock) 350Nm 3 / m 3 , Hydrogenation under the condition of hydrogen partial pressure 2.5MPa. The properties of heavy fraction of light cycle oil and heavy cycle oil fraction before and after hydrofining are shown in Table 5.

Embodiment 3

[0074] The heavy fraction of the light cycle oil is mixed with the mixed hydrogenation product of the heavy cycle oil and the light fraction of the light cycle oil for back refining.

[0075] The light fraction of the light cycle oil obtained in Examples 1 and 2, hydrogenated diesel oil (both accounting for 10% by weight of the atmospheric residue) and the atmospheric residue are mixed into the reactor, contacted with the FCC catalyst MLC-500, and heated at 500 ° C. , agent-to-oil ratio 8, space speed 8 hours -1 Cracking under certain conditions, fractionation after catalytic cracking to obtain dry gas, liquefied gas, gasoline, light cycle oil, heavy cycle oil, and heavy oil. The product distribution and gasoline properties are shown in Table 6 and Table 7, respectively.

[0076]From Table 6 and Table 7, it can be seen that the yield of gasoline obtained from the light fraction of 10 wt% light cycle oil and 10 wt% hydrogenated diesel oil from back refining increased by 11.94 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com