Methanation technology

A methanation and methanation reactor technology, applied in the petroleum industry, gas fuel, fuel and other directions, can solve the problems of unsuitable large-scale supply of natural gas, narrow application range, small production capacity, etc., to improve heat capacity, improve utilization rate, the effect of increasing the concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

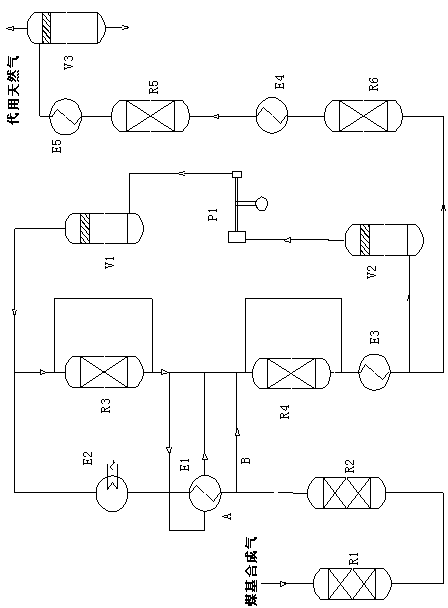

[0035] according to figure 1 The process flow shown, the pressure is 3.5MPa, the space velocity is 15000h -1After fine desulfurization of the synthetic gas, the total sulfur in the synthetic gas is less than 0.08ppm. After the water vapor shift, the fresh gas is divided into two streams (fresh gas A, B), and the composition (vol%) is: H 2 69.5, CH 4 8.21, CO 17.84, CO 2 1.95, H 2 O 2.5. 60% of the fresh air A passes through a heat exchanger to exchange heat with a reverse product gas to 290°C, heats it to 400°C through an electric heater, and then mixes with the circulating gas to form a reverse intake gas. The circulation ratio is 1.5, The gas inlet temperature is 300°C. After the reaction, the temperature rises to 630°C. After heat exchange, the gas from the first stage is mixed with fresh gas B at 460°C to form the second stage. The gas enters the second methanation reactor. The inlet temperature is 290°C. After the reaction The temperature was 610°C. The outlet gas...

Embodiment 2

[0037] according to figure 1 As shown in the process flow, the pressure is 3.5MPa and the space velocity is 25000h -1 After fine desulfurization of the synthetic gas, the total sulfur in the synthetic gas is less than 0.08ppm. After the water vapor shift, the fresh gas is divided into two streams (fresh gas A, B), and the composition (vol%) is: H 2 69.5, CH 4 8.21, CO 17.84, CO 2 1.95, H 2 O 2.5. 50% of the fresh air A passes through the heat exchanger to exchange heat with a reverse product gas to 280°C, heats it to 400°C through an electric heater, and then mixes with the circulating gas to form a reverse intake gas. The circulation ratio is 1.0, The gas inlet temperature is 290°C. After the reaction, the temperature rises to 670°C. After heat exchange, the gas from the first stage is mixed with fresh gas B at 450°C to form the second stage. The gas enters the second methanation reactor. The inlet temperature is 260°C. After the reaction The temperature is 680°C. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com