Process and device for integrally producing substitute natural gas by coal gasification and methanation

A technology for replacing natural gas and methanation catalysis, which is applied in the fields of gas fuel, production of combustible gas, granular/powder fuel gasification, etc. The effect of reducing methanation load, wide adaptability, and increasing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

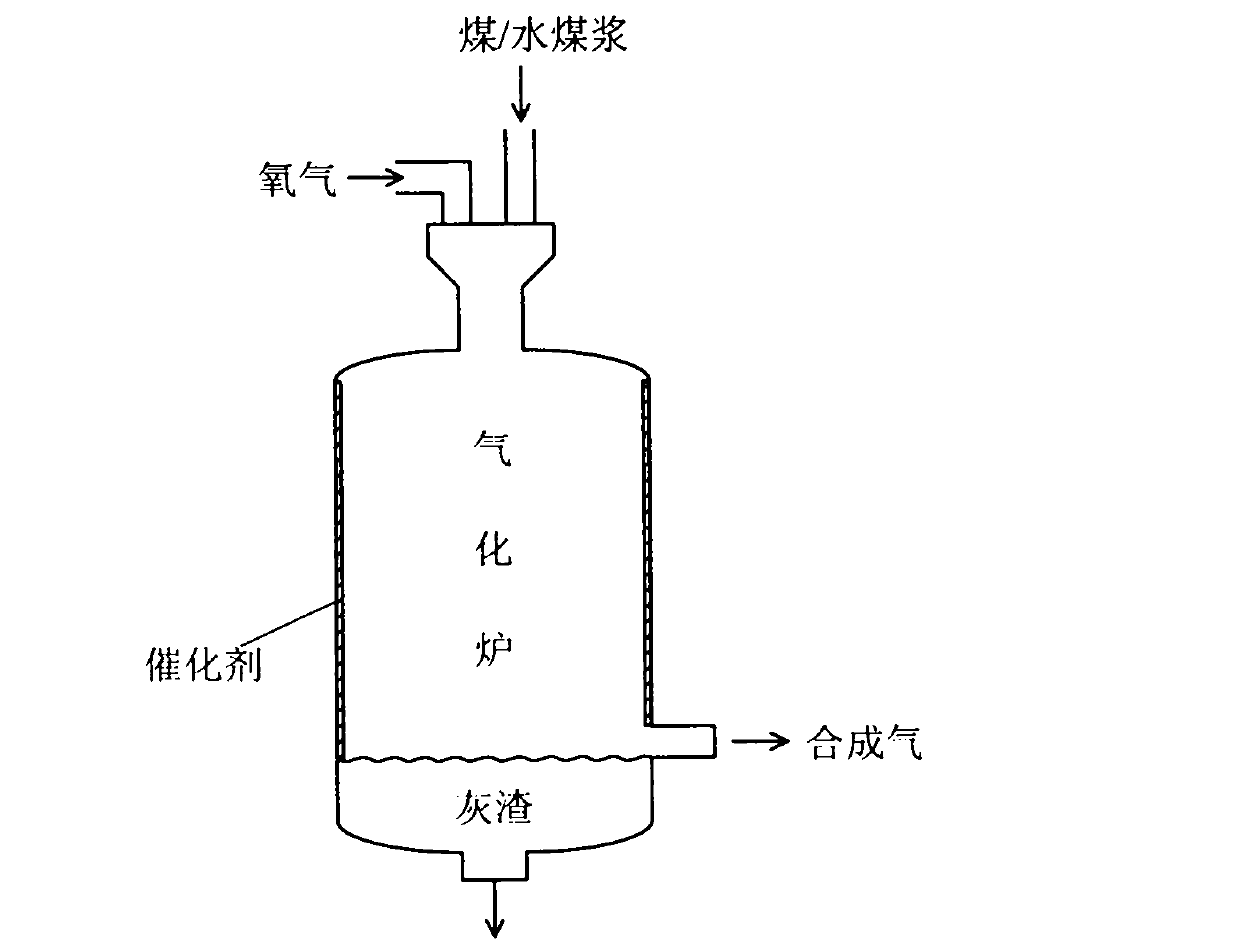

[0038] Embodiment 1 Integrated process and equipment based on coal water slurry gasification process

[0039] This embodiment provides a process and device for coal gasification and methanation integrated production of substitute natural gas based on a coal-water slurry gasification process (such as a Texaco coal-water slurry gasification process), such as figure 1 shown.

[0040] The integrated device provided in this embodiment includes a gasifier, a gas chiller, dust removal equipment, etc., wherein the gasifier used is a coal-water slurry entrained bed gasifier, and its lining is made of alumina, oxidized One or more refractory materials based on silicon, zirconia, etc., with the above-mentioned refractory material as the carrier, carrying nickel whose active component accounts for 5% of the total weight of the refractory material, and adding rare earth lanthanum as an auxiliary agent , the amount of which accounts for 2% of the total weight of the refractory material (ca...

Embodiment 2

[0044] Embodiment 2 Integrated process and equipment based on pulverized coal gasification process

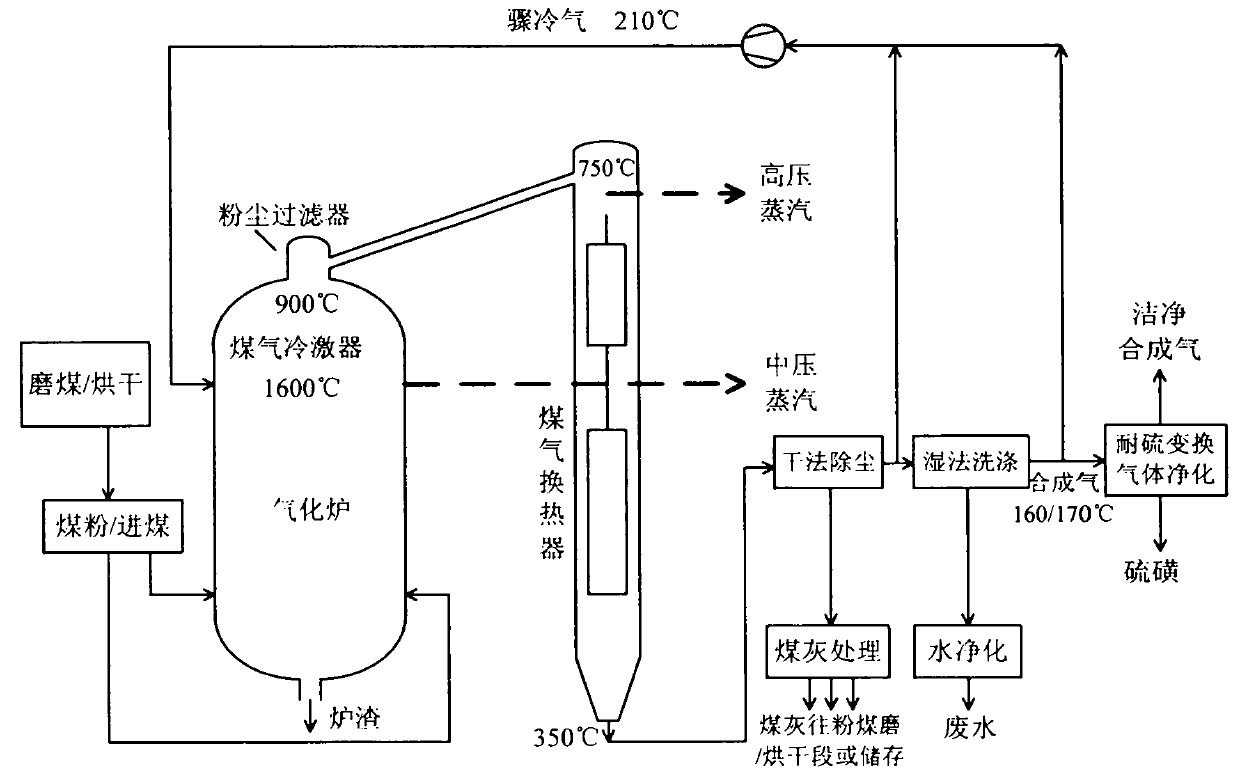

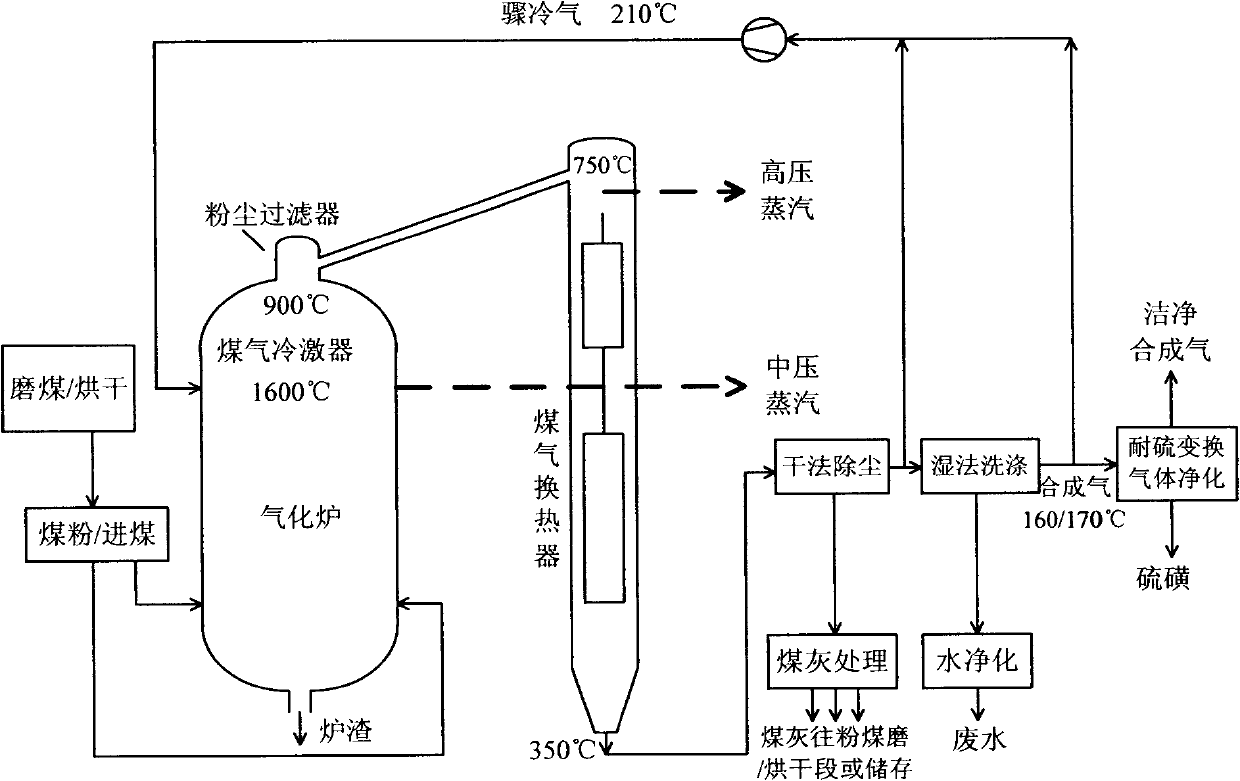

[0045] This embodiment provides a process and device for the integrated production of natural gas by coal gasification and methanation based on a pulverized coal gasification process (such as Shell pulverized coal gasification process), such as figure 2 shown.

[0046] The integrated production device provided in this embodiment includes a gasifier, a gas cooler (located on the upper part of the gasifier), a dust filter (ceramic material, located on the top of the gasifier), a gas heat exchanger (connected with the dust filter) Connection), and subsequent dry dedusting equipment, wet scrubbing equipment, gas circulation equipment (used to transport the treated gas to the gas chiller and gas heat exchanger to cool the high-temperature syngas).

[0047] Among them, the methanation catalytic strengthening treatment of each equipment in the device can include the following three ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com