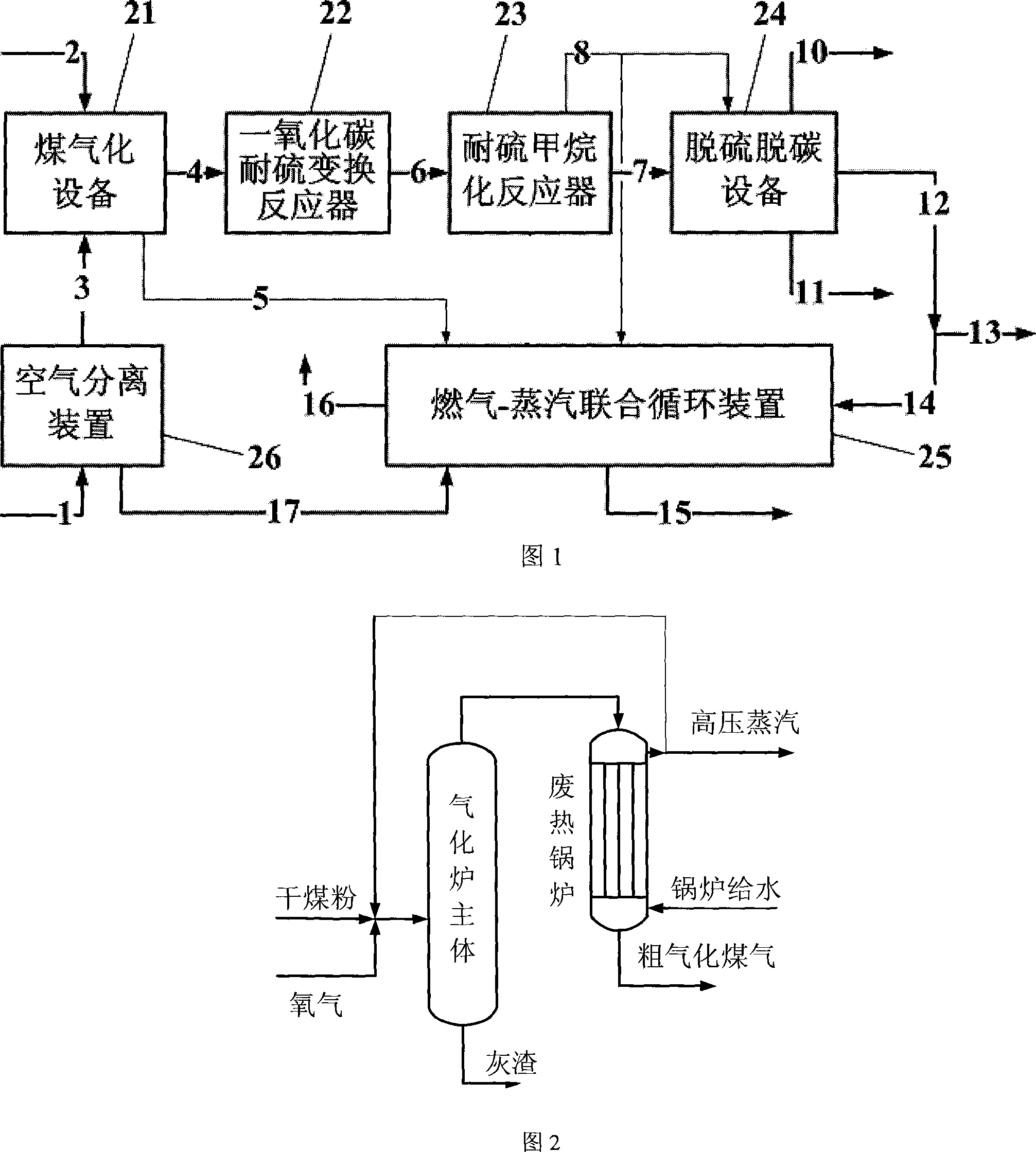

Gas-steam combined cycle system and technique based on coal gasification and methanation

A combined cycle, gas-steam technology, applied in the directions of oxygen/ozone/oxide/hydroxide, gas fuel, chemical industry, etc., to achieve the effect of reducing investment costs, increasing recovery, and reasonable purpose and quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] Embodiment: Based on the raw coal consumption of 5000 tons / day and the gas-steam combined cycle of Siemens V94.3a as the basis, the calculation of the overall performance of the system at base load is carried out for the embodiment.

[0033] The gasification coal used in Example 1 is bituminous coal from Binxian County, Shaanxi, and its composition and lower calorific value are shown in Table 1.

[0034] Table 1 Raw coal composition and calorific value

[0035] Elemental analysis

LHV

mad

2.52

Had

3.85

Oad

12.73

Nad

0.36

sad

0.46

CAD

69.94

Aad

10.14

(MJ / kg)

27.7

[0036] Table 2 embodiment overall performance data

[0037] System solutions

Example 1

Example 2

Coal supply (t / d)

Vaporization pressure (MPa)

High pressure steam pressure (MPa)

Raw gas temperature (℃)

Sulfur-resistant methanation reaction pressure (MPa)

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com