Synthesis gas methanation reaction method

A technology of methanation reactor and gas methane, which is applied in the direction of gas fuel, petroleum industry, fuel, etc., and can solve problems such as complex process, low conversion rate of methanation reaction, and many heat exchange equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

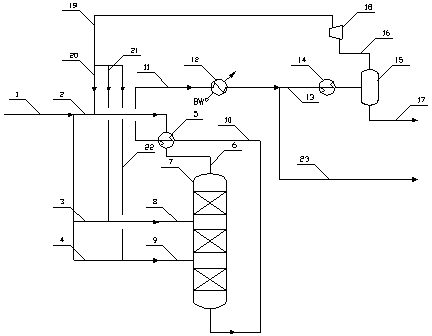

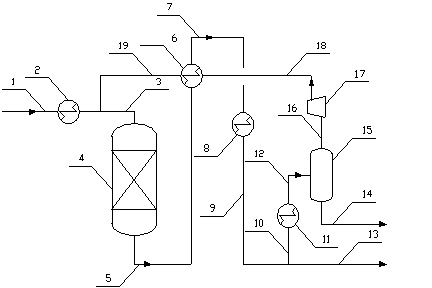

[0023] 2 billion Nm 3 / year synthetic gas methanation to substitute natural gas plant (annual operating hours 8,000 hours), using figure 1 With advanced technology, the raw syngas is divided into three shares evenly at a pressure of 3.3MPa and a temperature of 30°C. The circulating gas from the compressor has a pressure of 3.3MPa and a temperature of 49°C. It is divided into three streams according to the ratio of 4:4:2, and is mixed with the raw material synthesis gas to enter the third-stage catalyst bed of the fixed-bed reactor, so that the temperature of the mixed gas entering the middle-stage catalyst bed is The temperature of the mixed gas entering the lower catalyst bed is 438°C. The mixed gas entering the upper catalyst bed first exchanges heat with the reaction gas in the heat exchanger, and then rises to 300°C before entering the catalyst bed. After the reaction product comes out of the reactor at 552°C, heat the mixed gas as mentioned above, the temperature of the ...

Embodiment 2

[0026] 2 billion Nm 3 / year synthetic gas methanation to replace natural gas installations, using figure 1 The process technology, the reaction gas is divided into two streams, 11% of the reaction gas is used as the feed of the lower methanation reactor, and 89% of the reaction gas is used as the cycle gas to mix with the raw synthesis gas. The temperature of the mixed gas entering the middle catalyst bed is 323°C, the temperature of the mixed gas entering the lower catalyst bed is 406°C, and the temperature of the methanation reaction gas product is 510°C. Other conditions are with embodiment 1. The conversion rate of the methanation reaction of this device is 77.0%, and the energy consumption of the compressor is 6585KW.

[0027]

Embodiment 3

[0029] 2 billion Nm 3 / year synthetic gas methanation to replace natural gas installations, using figure 1 The raw material synthesis gas is divided into three shares on average at 5.5MPa and 20°C, and the circulating gas exits the compressor at a temperature of 25°C and a pressure of 5.5MPa. Each catalyst bed of the stage fixed bed reactor makes the temperature of the mixed gas entering the middle catalyst bed be 379°C, the temperature of the mixture entering the lower stage catalyst bed is 448°C, and the product temperature of the methanation reactor is 567°C. Other process conditions are with embodiment 1.

[0030] The conversion rate of the methanation reaction of this device is 73.2%, and the energy consumption of the compressor is 2996KW.

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com