Synthesis gas methanation catalyst and preparation thereof

The technology of catalyst and auxiliary agent is applied in the field of synthesis gas methanation catalyst and its preparation, which can solve the problems of easy sintering of active components and poor heat transfer effect of catalyst, and achieve the effects of avoiding over-temperature sintering and high activity stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

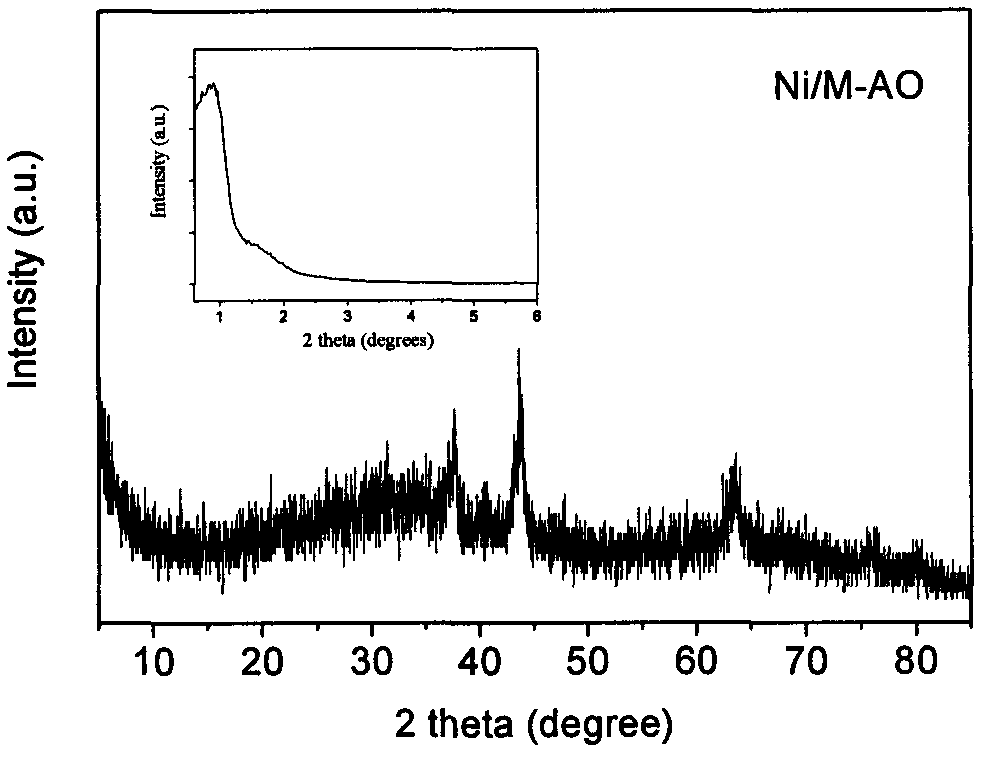

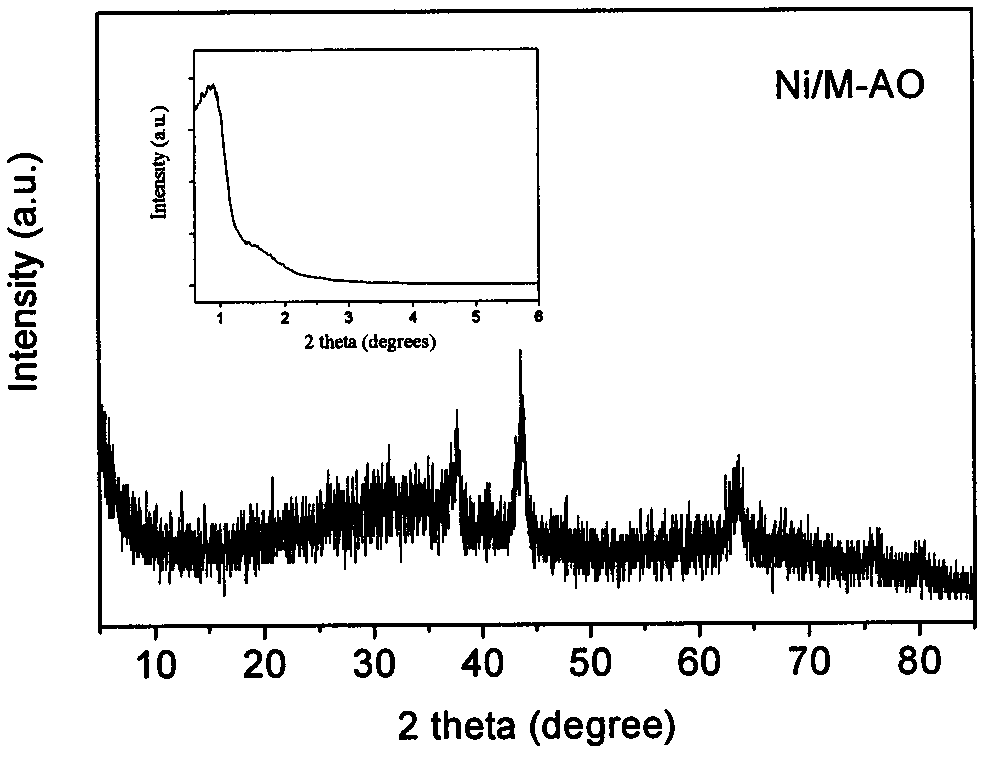

specific Embodiment approach 1

[0023] Weigh 1g of P123 and dissolve it in ethanol. After fully dissolving, add 2g of aluminum isopropoxide, stir at 40°C for 4h, place in a drying oven at 60°C for 48h at a constant temperature, and roast at 400°C for 4h to obtain mesoporous alumina. The specific surface area 329.5m 2 / g, pore volume 0.485cm3 / g, pore diameter 4.9nm. Weigh 2.48 grams of nickel nitrate and 0.95 grams of cerium nitrate to prepare solutions respectively, immerse 2.5 grams of mesoporous alumina carrier in the solution of cerium nitrate, dry at 100°C for 3 hours, and roast at 450°C for 2 hours, then Immerse in a nickel nitrate solution, dry the impregnated sample at 120°C for 2 hours, and calcinate at 450°C for 4 hours to obtain a supported nickel catalyst; then immerse it in a solution prepared with 0.6 g of iridium nitrate, and dry the impregnated sample at 120°C 2h, calcination at 500°C for 4h to obtain a modified catalyst, which is pressed into tablets to obtain catalyst particles of 40-60 mesh...

specific Embodiment approach 2

[0024] According to the same method as in Embodiment 1, a mesoporous alumina-supported nickel catalyst was synthesized. Then it was immersed in a solution prepared with 0.4 g of magnesium nitrate. The impregnated sample was dried at 120° C. for 3 hours and calcined at 500° C. for 3 hours to obtain a modified catalyst, which was pressed into tablets to obtain catalyst particles of 40-60 mesh. For the methanation reaction of syngas, the temperature is 400°C, the pressure is 1.5MPa, and the space velocity is 9000h -1 , H in syngas 2 The / CO ratio was 3. During the reaction time of 200 hours, the conversion rate of carbon monoxide was 90%, and the selectivity of methane was 100%.

specific Embodiment approach 3

[0025] Weigh 1g of P123 and dissolve it in ethanol. After fully dissolving, add 2.5g of aluminum isopropoxide, stir at 40°C for 4h, place in a drying oven at 60°C for 48h at a constant temperature, and roast at 400°C for 4h to obtain mesoporous alumina. Surface area is 254.2m 2 / g, pore volume 0.405cm3 / g, pore diameter 3.42nm. . Weigh 2.48 grams of nickel nitrate and 0.95 grams of cerium nitrate to prepare solutions respectively. First, immerse 2.5 grams of mesoporous alumina carrier in the solution of cerium nitrate. After impregnation, the sample is dried at 120°C for 2 hours, and then roasted at 450°C. Then it is immersed in the nickel nitrate solution, the sample after immersion is dried at 120°C for 2h, and roasted at 450°C for 4h to obtain the supported nickel catalyst; Drying at ℃ for 3 hours, calcining at 500 ℃ for 4 hours to obtain a modified catalyst, and pressing it into tablets to obtain catalyst particles of 40-60 mesh. For the methanation reaction of syngas, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com