Methanation method for synthesizing substitute natural gas by using industrial hydrocarbon exhaust gas

A technology to replace natural gas and hydrocarbon industries, applied in the petroleum industry, gas fuel, fuel, etc., can solve the problems of low utilization of hydrocarbon resources, high operating costs, and poor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

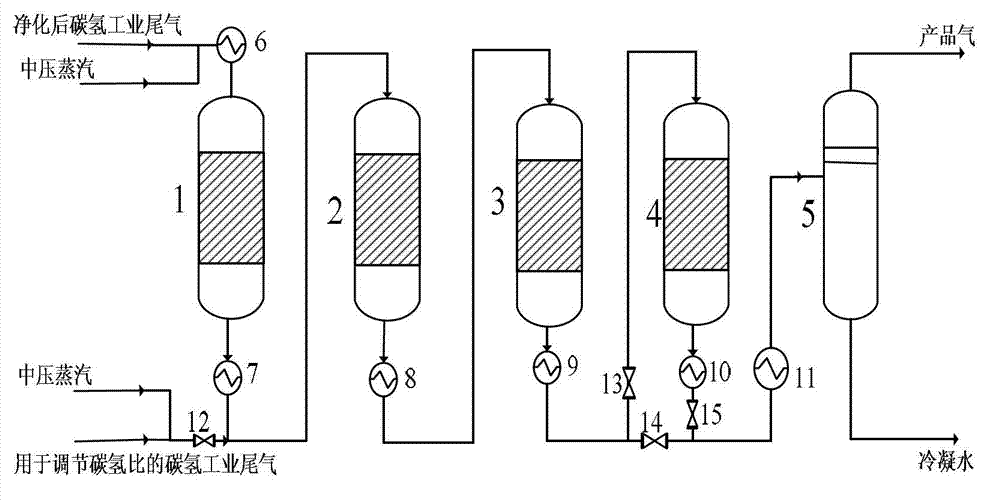

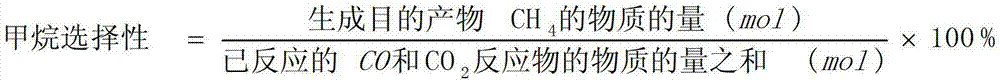

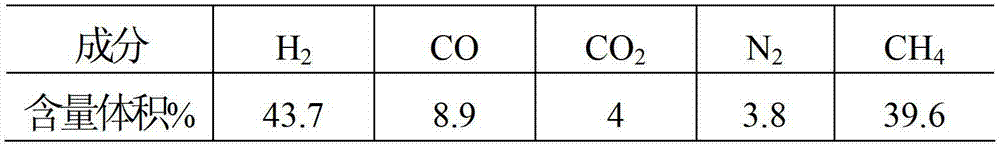

[0091] Embodiment 1: Synthesis of substitute natural gas by tail gas of hydrocarbon industry

[0092] According to the method described in the specification sheet of this application, the hydrocarbon industrial tail gas from a coking plant used in this embodiment was analyzed, and the analysis results are listed in Table 1:

[0093] Table 1: Analysis results of gas composition of tail gas raw material gas in hydrocarbon industry

[0094]

[0095] According to the data listed in Table 1, the contents of hydrogen, carbon monoxide and carbon dioxide meet the relational formula (H 2 -3CO) / CO 2 =4 requirements.

[0096] The implementation steps of this embodiment are as follows:

[0097] The purified hydrocarbon industrial tail gas that removes its various mechanical impurities is preheated by the preheater 6 to reach a temperature of 250°C, and then enters the first-stage methanation reactor 1, at an inlet temperature of 280°C, an inlet pressure of 3.0MPa, and an outlet temp...

Embodiment 2

[0104] Embodiment 2: Synthesis of substitute natural gas by tail gas of hydrocarbon industry

[0105] According to the method described in the specification sheet of this application, the hydrocarbon industrial tail gas from a chemical plant used in this embodiment was analyzed, and the analysis results are listed in Table 3:

[0106] Table 3: Gas Composition Analysis Results of Hydrocarbon Industry Tail Gas Raw Gas

[0107]

[0108] According to the data listed in Table 3, the contents of hydrogen, carbon monoxide and carbon dioxide meet the relational formula (H 2 -3CO) / CO 2 =4 requirements.

[0109] The implementation steps of this embodiment are as follows:

[0110] The purified hydrocarbon industrial tail gas that removes its various mechanical impurities is preheated by the preheater 6 to reach a temperature of 200°C, and then enters the first-stage methanation reactor 1 at an inlet temperature of 230°C, an inlet pressure of 1.0MPa, and an outlet temperature of 350...

Embodiment 3

[0117] Embodiment 3: Synthesis of substitute natural gas by tail gas of hydrocarbon industry

[0118] According to the method described in the specification sheet of this application, the hydrocarbon industrial tail gas from a coke plant used in this embodiment was analyzed, and the analysis results are listed in Table 5:

[0119] Table 5: Gas Composition Analysis Results of Hydrocarbon Industry Tail Gas Raw Gas

[0120]

[0121] According to the data listed in Table 5, the contents of hydrogen, carbon monoxide and carbon dioxide meet the relational formula (H 2 -3CO) / CO 2 =4 requirements.

[0122] The implementation steps of this embodiment are as follows:

[0123] The purified hydrocarbon industrial tail gas that removes its various mechanical impurities is preheated by the preheater 6 to a temperature of 300°C, and then enters the first-stage methanation reactor 1, at an inlet temperature of 350°C, an inlet pressure of 5.0MPa, and an outlet temperature of 650°C , The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com