Method for coproducing substitute natural gas through coal liquefaction

A technology for substituting natural gas and coal-to-oil, which is applied in the petroleum industry, the preparation of gaseous fuels, liquid hydrocarbon mixtures, etc., can solve the problems of no combined process of coal-to-oil and coal-to-natural gas, and achieve the goal of reducing investment and operating costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

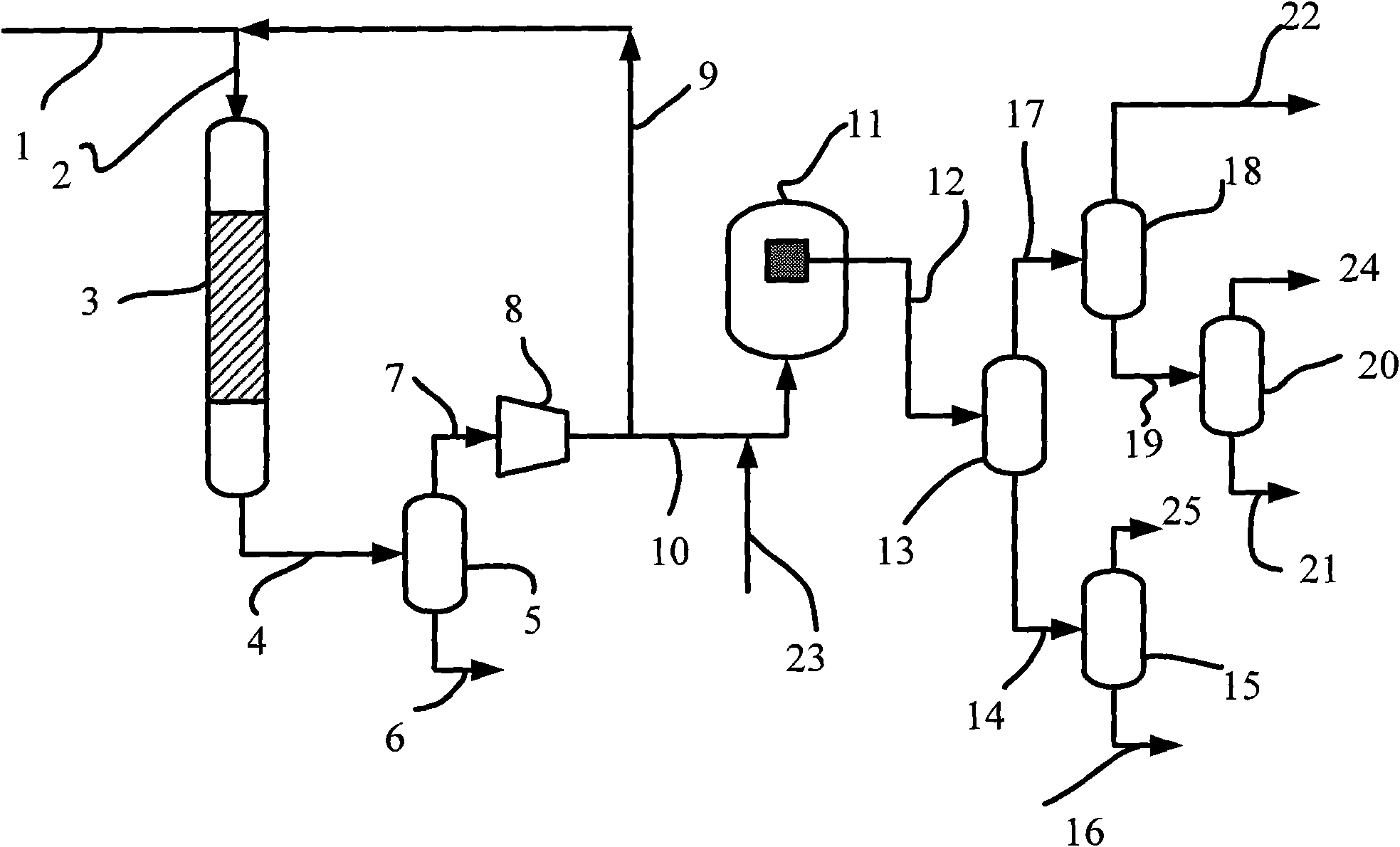

[0037] This embodiment adopts figure 1 The process flow shown.

[0038] The specific process is as follows: coal is gasified to obtain 2 The synthesis gas including CO, the synthesis gas enters the methanation reactor 3 through the pipeline 1 and the pipeline 2, and reacts under the action of the methanation catalyst, and the reaction effluent enters the high-pressure separator 5 through the pipeline 4 for gas-liquid separation, The resulting condensed liquid flow, i.e. liquid I, is discharged from the system through line 6, and the resulting gas flow, i.e. gas I, enters compressor 8 through line 7, and after being pressurized by the compressor, part of gas I is recycled back to methanation reactor 3 through line 9 Participate in reactions further. The gas I not recycled back to the methanation reactor 3 enters the Fischer-Tropsch synthesis reactor 11 through the pipeline 10, and undergoes a Fischer-Tropsch synthesis reaction under the action of the Fischer-Tropsch synthesis...

Embodiment 2

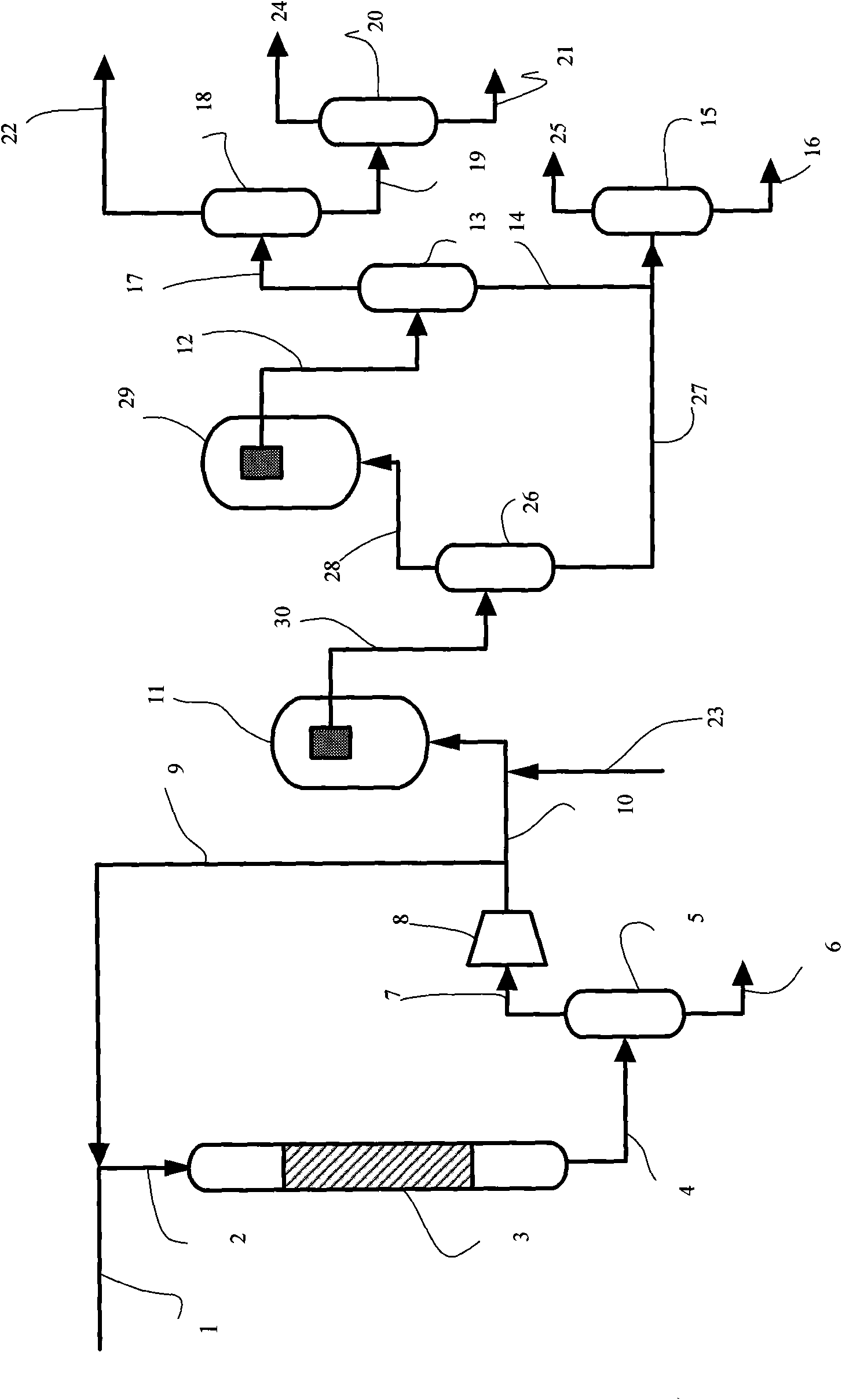

[0048] This embodiment adopts figure 2 The process flow shown.

[0049] The specific process is as follows: coal is gasified to obtain 2 The synthesis gas including CO, the synthesis gas enters the methanation reactor 3 through the pipeline 1 and the pipeline 2, and reacts under the action of the methanation catalyst, and the reaction effluent enters the high-pressure separator 5 through the pipeline 4 for gas-liquid separation, The resulting condensed liquid flow, i.e. liquid I, is discharged from the system through line 6, and the resulting gas flow, i.e. gas I, enters compressor 8 through line 7, and after being pressurized by the compressor, part of gas I is recycled back to methanation reactor 3 through line 9 Participate in reactions further. The gas I that is not recycled back to the methanation reactor 3 enters the first Fischer-Tropsch synthesis reactor 11 through the pipeline 10, and carries out the Fischer-Tropsch synthesis reaction under the action of the Fische...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com