Methanation catalyst used for preparing substitute natural gas from synthesis gas, and preparation method and application thereof

A methanation catalyst and catalyst technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, gas fuels, etc., to improve low-temperature methanation activity, thermal stability, The effect of carbon properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

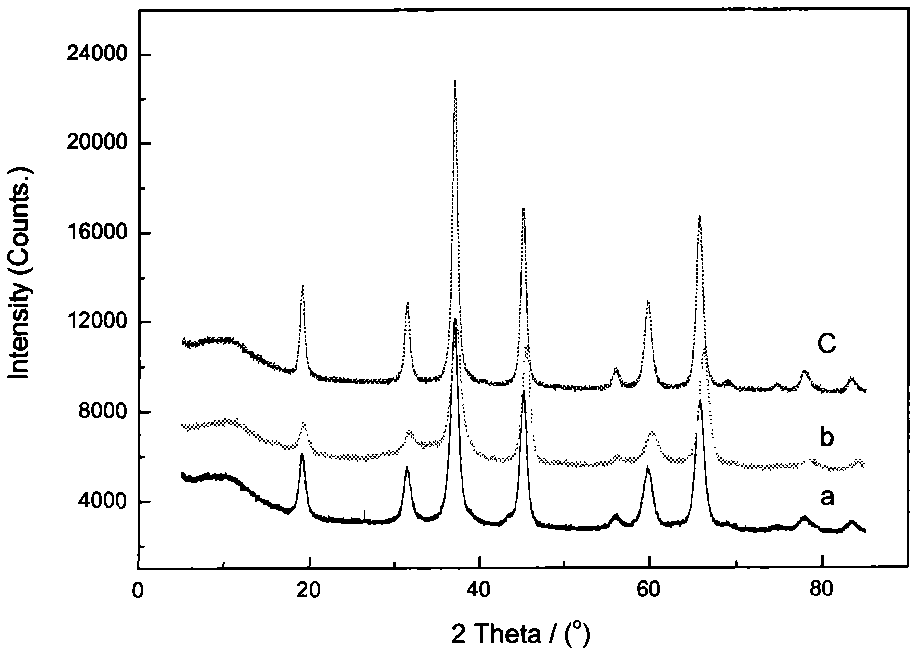

Image

Examples

Embodiment 1

[0030] Embodiment 1 nickel-lanthanum / magnesium-Al 2 o 3

[0031] Weigh the treated Al 2 o 3 Microsphere 10g, denoted as A.

[0032] Measure 20.56mL of 2M magnesium nitrate solution, and concentrate the solution to about 7.5mL by heating. Put A into the solution for immersion, and the immersion time is 8 hours. After impregnation, put A into a muffle furnace and heat at a high temperature at 700°C for 6 hours to obtain B.

[0033] Measure 12.78ml of 2M nickel nitrate solution and 2.4mL of 0.3M lanthanum nitrate solution, mix well, heat and concentrate the solution to about 7.5mL. Put B into the mixed solution and soak for 8 hours. After impregnation, put B into a muffle furnace and heat at a high temperature at 600°C for 6 hours to obtain a catalyst containing 15% nickel, 10% magnesium and 1% lanthanum.

Embodiment 2

[0034] Embodiment 2 nickel-magnesium-lanthanum / magnesium-Al 2 o 3

[0035] Weigh the processed Al 2 o 3 Microsphere 10g, denoted as A.

[0036] Measure 20.56mL of 2M magnesium nitrate solution, and concentrate the solution to about 7.5mL by heating. Put A into the solution for immersion, and the immersion time is 8 hours. After impregnation, put A into a muffle furnace and heat at a high temperature at 900°C for 6 hours to obtain B.

[0037] Measure 12.78ml of 2M nickel nitrate solution, 10.28mL of 2M magnesium nitrate solution, and 6mL of 0.3M lanthanum nitrate solution, mix well, heat and concentrate the solution to about 7.5mL. Put B into the mixed solution and soak for 8 hours. After impregnation, put B into a muffle furnace and heat at a high temperature at 630°C for 6 hours to obtain a catalyst containing 15% nickel, 15% magnesium and 2.5% lanthanum.

Embodiment 3

[0038] Example 3 Nickel-lanthanum / magnesium-Al 2 o 3

[0039] Weigh the treated Al 2o 3 Microsphere 10g, denoted as A.

[0040] Measure 20.56mL of 2M magnesium nitrate solution, and concentrate the solution to about 7.5mL by heating. Put A into the solution for immersion, and the immersion time is 8 hours. After impregnation, put A into a muffle furnace and heat at a high temperature at 900°C for 6 hours to obtain B.

[0041] Measure 6.39ml of 2M nickel nitrate solution and 12mL of 0.3M lanthanum nitrate solution, mix well, heat and concentrate the solution to about 7.5mL. Put B into the mixed solution and soak for 8 hours. After impregnation, put B into a muffle furnace and heat at a high temperature at 700°C for 8 hours to obtain a catalyst containing 7.5% nickel, 10% magnesium and 5% lanthanum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com