Preparation method of synthetic gas methanation catalyst

A technology of catalysts and additives, which is applied in the field of synthesis gas methanation catalyst preparation, can solve the problems of easy sintering stability of active components, difficulty in controlling the dispersion of catalyst particles, etc., and achieve good catalyst dispersion, mild conditions, and pore structure adjustable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

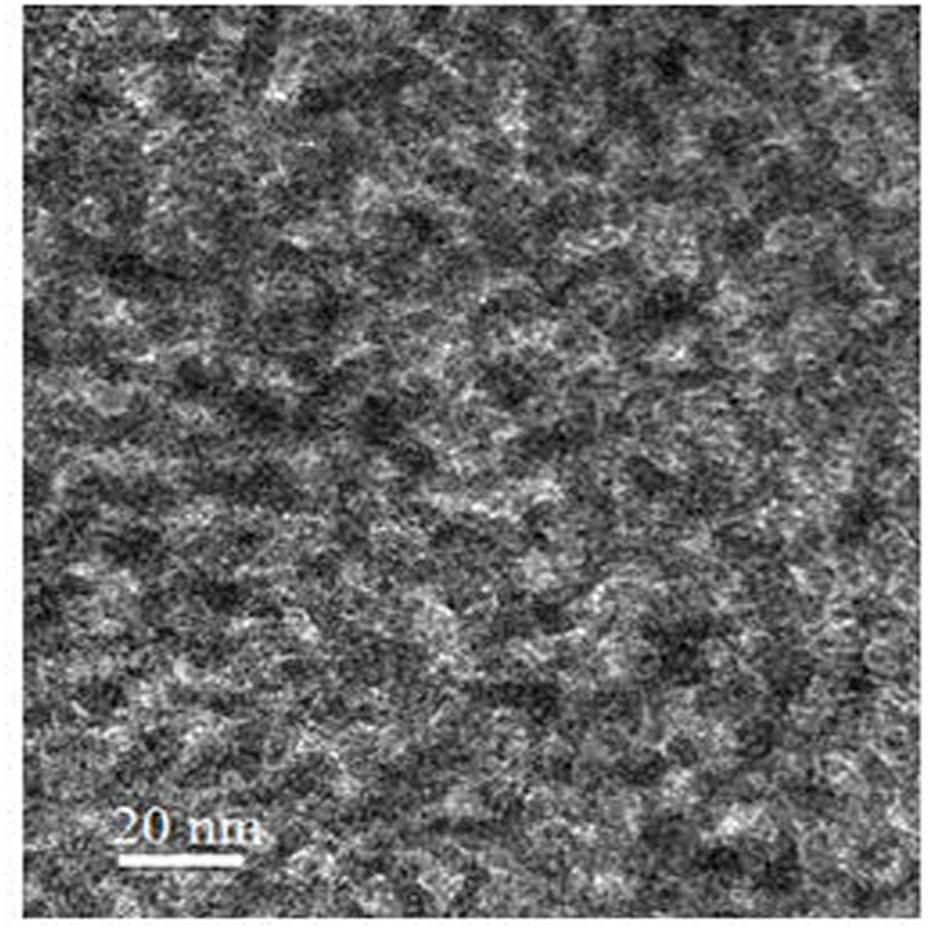

[0019] Weigh 1.5 g of F127 and dissolve it in ethanol. After fully dissolving, add 2 g of aluminum isopropoxide, continue to stir for 2 h, weigh 0.3 g of nickel nitrate and add it to the above solution, 40 o After stirring at C constant temperature for 4 h, place in a drying oven at 60°C for constant temperature drying for 48 h, and after 400 o C was calcined for 4h to obtain a nickel catalyst with a loading weight percentage of 10%. The specific surface area of the catalyst synthesized in this embodiment is 239 m 2 / g, pore volume 0.26 cm 3 / g, with an average pore size of 8 nm.

specific Embodiment approach 2

[0020] Weigh 1 g of F127 and dissolve it in ethanol. After fully dissolving, add 2 g of aluminum isopropoxide, continue to stir for 2 h, weigh 0.3 g of nickel nitrate and add it to the above solution, 40 o C was stirred at a constant temperature for 4 h, placed in a drying oven at 60°C for 48 h at a constant temperature, and after 500 o C was calcined for 4h to obtain a nickel catalyst with a loading weight percentage of 10%. The specific surface area of the catalyst is 324 m 2 / g, pore volume 0. 37 cm 3 / g, with an average pore size of 6 nm.

specific Embodiment approach 3

[0021] Weigh 1 g of F127 and dissolve it in ethanol. After fully dissolving, add 2 g of aluminum nitrate, continue to stir for 2 h, weigh 0.3 g of nickel nitrate and add it to the above solution, 40 o After stirring at C constant temperature for 4 h, place it in a drying oven at 60°C for 48 h at constant temperature, and after 500 o C was calcined for 4h to obtain a nickel catalyst with a loading weight percentage of 10%. The specific surface area of the catalyst is 254 m 2 / g, pore volume 0. 34 cm 3 / g, with an average pore diameter of 3.5 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com