Process combined oil refining and gasification

A process method and a combined technology, applied in the process field of combining oil refining and gasification, can solve the problems that have not been properly solved and the impact of development space, etc., and achieve the effects of short reaction time, high reaction rate and high operating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

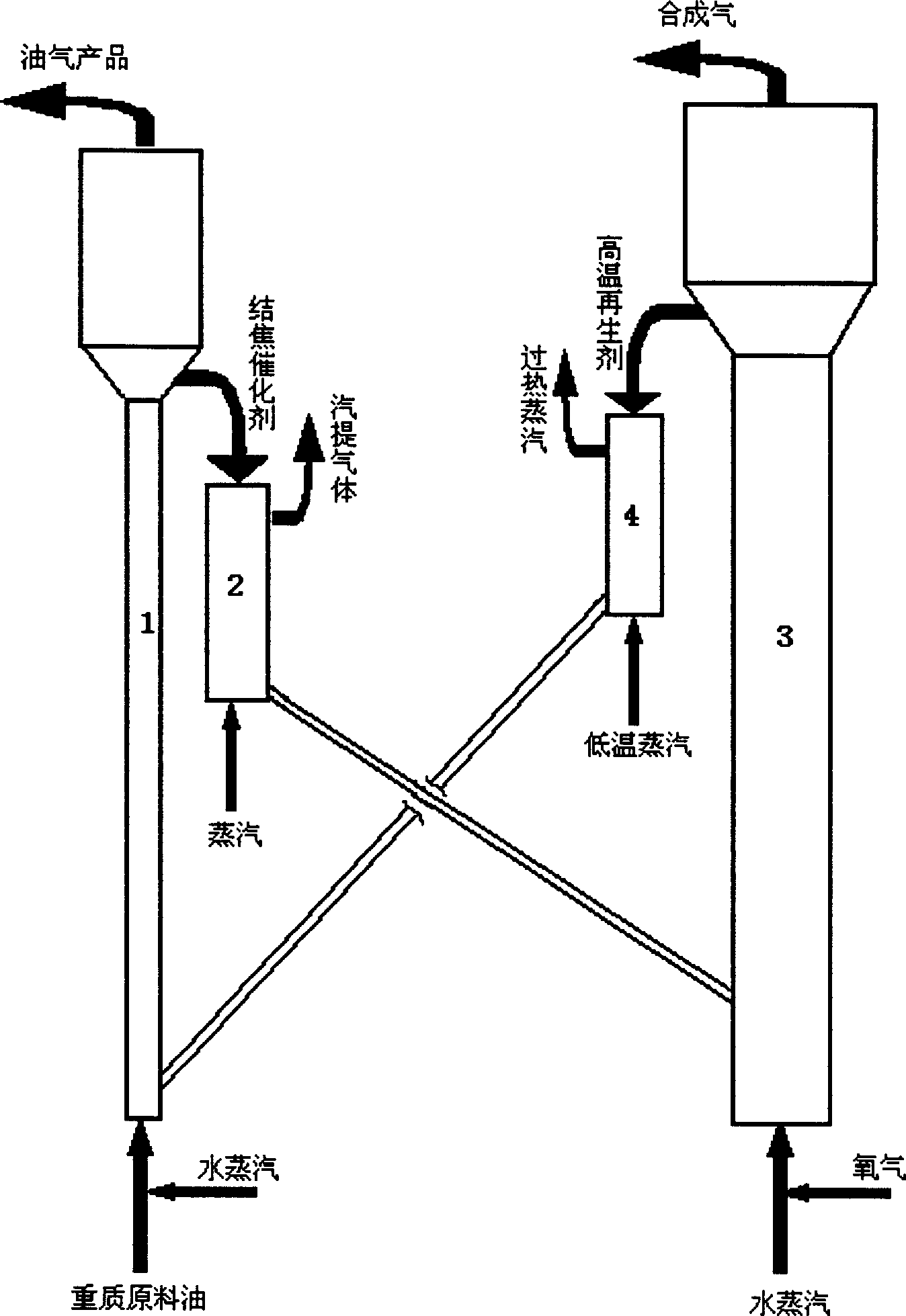

Image

Examples

Embodiment 1

[0035] This example shows that the method provided by the present invention can not only significantly improve the quality of heavy petroleum hydrocarbons, but also produce a certain amount of gasoline and diesel, and can also provide cheap raw material gas for the subsequent hydrogen production process.

[0036] In the fixed fluidized bed reactor, the semi-synthetic silica-alumina produced by spray drying technology is used as the coke transfer agent to make it contact and react with Iranian residual oil. for 10h -1 and 5h -1 , the product distribution after treatment is shown in Table 2, it can be seen that the ratio of diesel to steam is greater than 1. The residual carbon and metal content of the product heavy oil are listed in Table 3. Compared with the raw material oil, the residual carbon and metal content of the product heavy oil are significantly reduced.

[0037] Test No.

N0.1

N0.2

Raw oil

Agent to ...

Embodiment 2

[0041] This example shows that the method provided by the present invention can not only significantly improve the quality of heavy petroleum hydrocarbons, but also produce a certain amount of gasoline and diesel, and can also provide cheap raw material gas for the subsequent hydrogen production process.

[0042] In the fixed fluidized bed reactor, quartz sand is used as the coke transfer agent to make it contact and react with Iranian residual oil. The operating temperatures are 400°C and 450°C respectively, the agent-oil ratio is 5, and the weight hourly space velocity is 10h -1 , the product distribution after treatment is shown in Table 4. It can be seen that the diesel-gasoline ratio can be around 1 when heavy oil is treated at a higher temperature. The residual carbon and metal content of the product heavy oil are listed in Table 5. Compared with the raw material oil, the residual carbon and metal content of the product heavy oil are significantly lower.

[0043] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com