Fluid continuous reactor and application thereof

A technology of reactors and fluids, applied in chemical methods for reacting liquids with liquids, chemical/physical/physicochemical fixed reactors, chemical instruments and methods, etc., can solve the problem of difficult discharge and high-viscosity material adhesion Strong, high-viscosity materials adhere to the rotor, stator mixed tooth gap and other problems, to achieve the effect of smooth discharge, stable quality and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

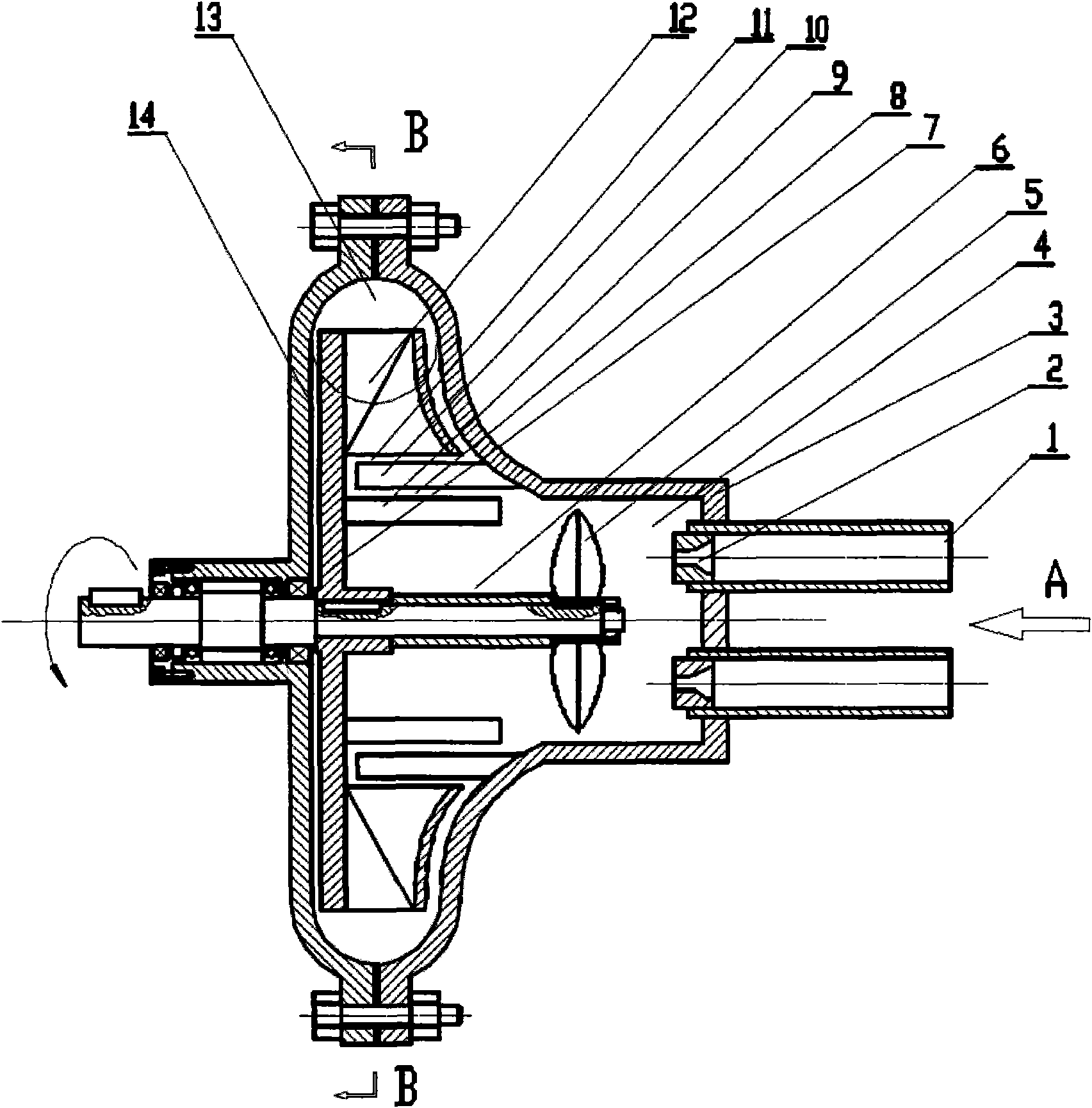

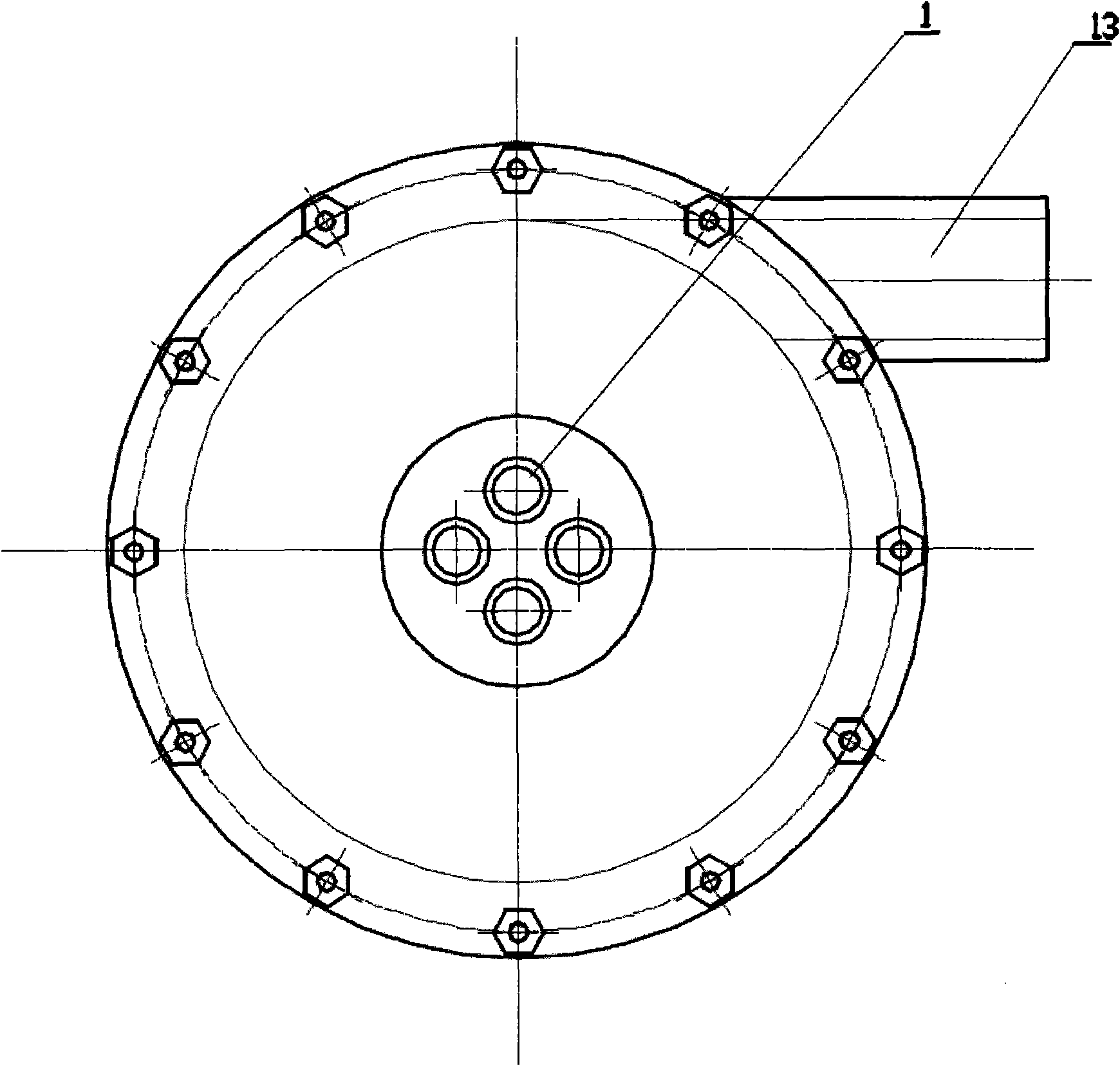

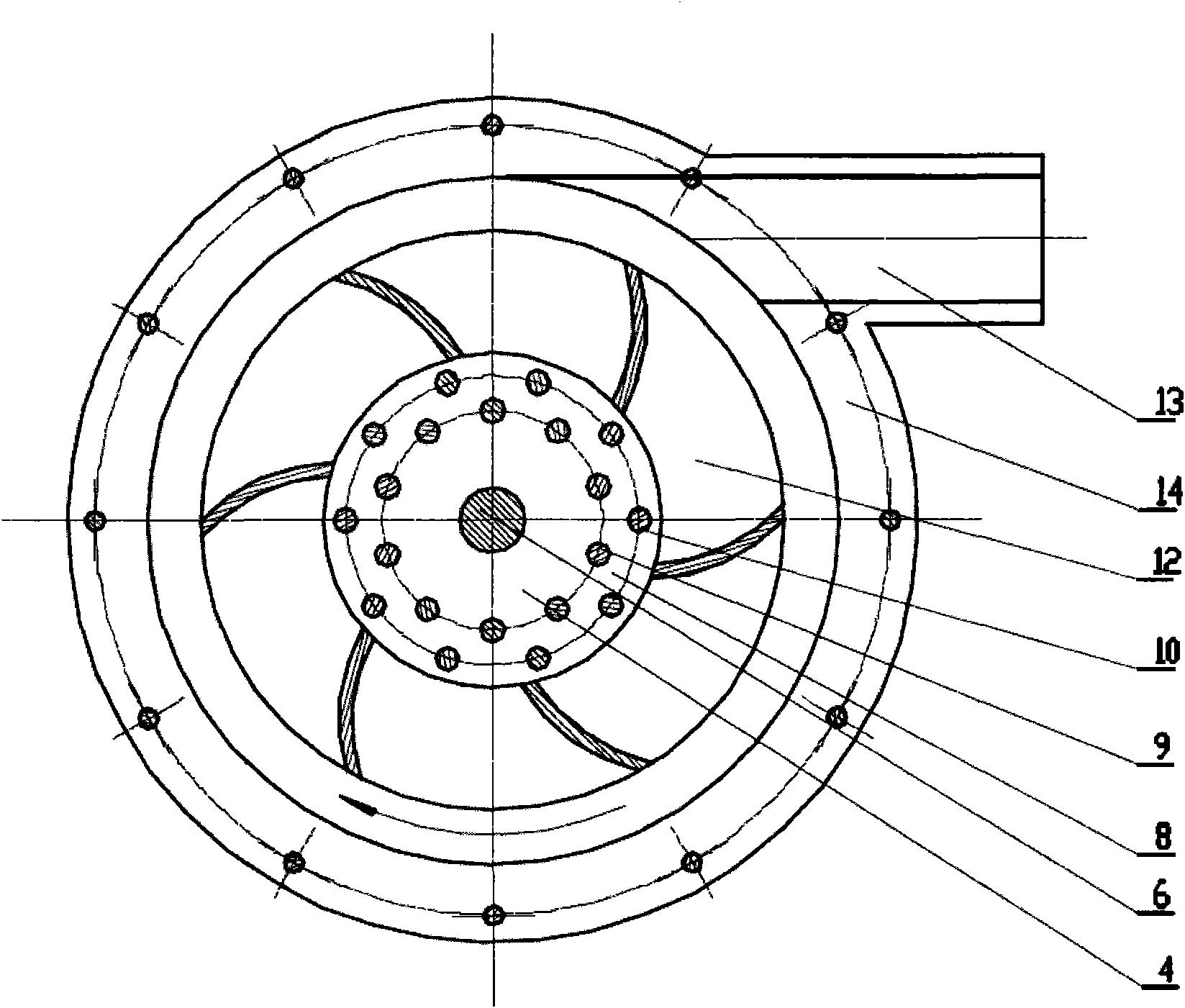

[0030] In the method for preparing NaY molecular sieve gel provided by the present invention, aluminum sulfate, water glass and directing agent are metered through respective feeding pipes according to the weight ratio of (1~1.2): (9~11): (4.6~5.5) Introduced into the fluid continuous reactor, the liquid raw material in the mixing chamber 4 is quickly atomized into fine droplets through the feed atomizing nozzle 2, so that several liquids can contact and react instantly in the mixing chamber 4, and the mixing blades in the mixing chamber 4 5. Further, several kinds of atomized liquids are stirred rapidly and mixed into a uniform material; then enter the crushing chamber 8, and undergo the relative motion of the stator teeth and the rotor teeth for grinding and crushing, and crush the blocky materials that may be produced during the reaction. Under the action of centrifugal force, the final reaction material is thrown away from the mixing chamber and enters the blade 12 of the c...

Embodiment 1

[0044] Embodiment 1 illustrates the method for synthesizing NaY molecular sieve gel with aluminum sulfate, water glass and directing agent using the fluid continuous reactor provided by the present invention.

[0045] Synthesize NaY molecular sieve gel with aluminum sulfate, water glass and directing agent, first according to the proportion of 15.3Na 2 O:Al 2 o 3 : 10SiO 2 :223H 2 O to prepare the directing agent, respectively use three metering pumps to direct the directing agent, aluminum sulfate (Al 2 o 3 content 7.4%), water glass (SiO 2 Content 28.4%, Na 2 O content 8.9%) is divided into three pipelines and input to such as attached figure 1 In the shown continuous reactor, control directing agent 198kg / h, aluminum sulfate 168Kg / h, water glass 304.2kg / h continuous and stable feeding; Obtain uniform NaY gel (proportioning is 0.6Na 2 O:Al 2 o 3 : 12SiO2 2 : 134H 2 O), the solid content of the gel is 32.6%, run for 30 minutes, and continuously mix to obtain about...

Embodiment 2

[0054] Embodiment 2 illustrates adopting the fluid continuous reactor provided by the present invention, the method for continuously synthesizing silica sol in this reactor with dilute sulfuric acid and water glass.

[0055] Use 20% dilute sulfuric acid at a delivery rate of 160kg / h and 12% water glass at a delivery rate of 480kg / h, continuously mix and react to form silica sol through this continuous reactor, and quickly mix a solid content of 420kg after 40 minutes of operation About 9% silica sol, the pH value of the colloid is 2.0; the whole process is continuous and automatic, the reactor runs smoothly, the material in and out is stable, and the silica sol produced by the reaction is clear and transparent, without forming agglomerates and granular gels, and placed statically It is basically stable within 32 hours without any coagulation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com