Electrodeionization water-purifying device and method for recovering cation and anion without scaling

An anion and cation, electrodeionization technology, applied in separation methods, ion exchange water/sewage treatment, dispersed particle separation, etc., can solve the problem of increasing the inhomogeneity of the internal resistance of the membrane stack, the non-recyclable use of polar water and concentrated water, Problems such as secondary pollution of resin acid-base regeneration, to achieve the effect of improving resource utilization, reducing energy consumption, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

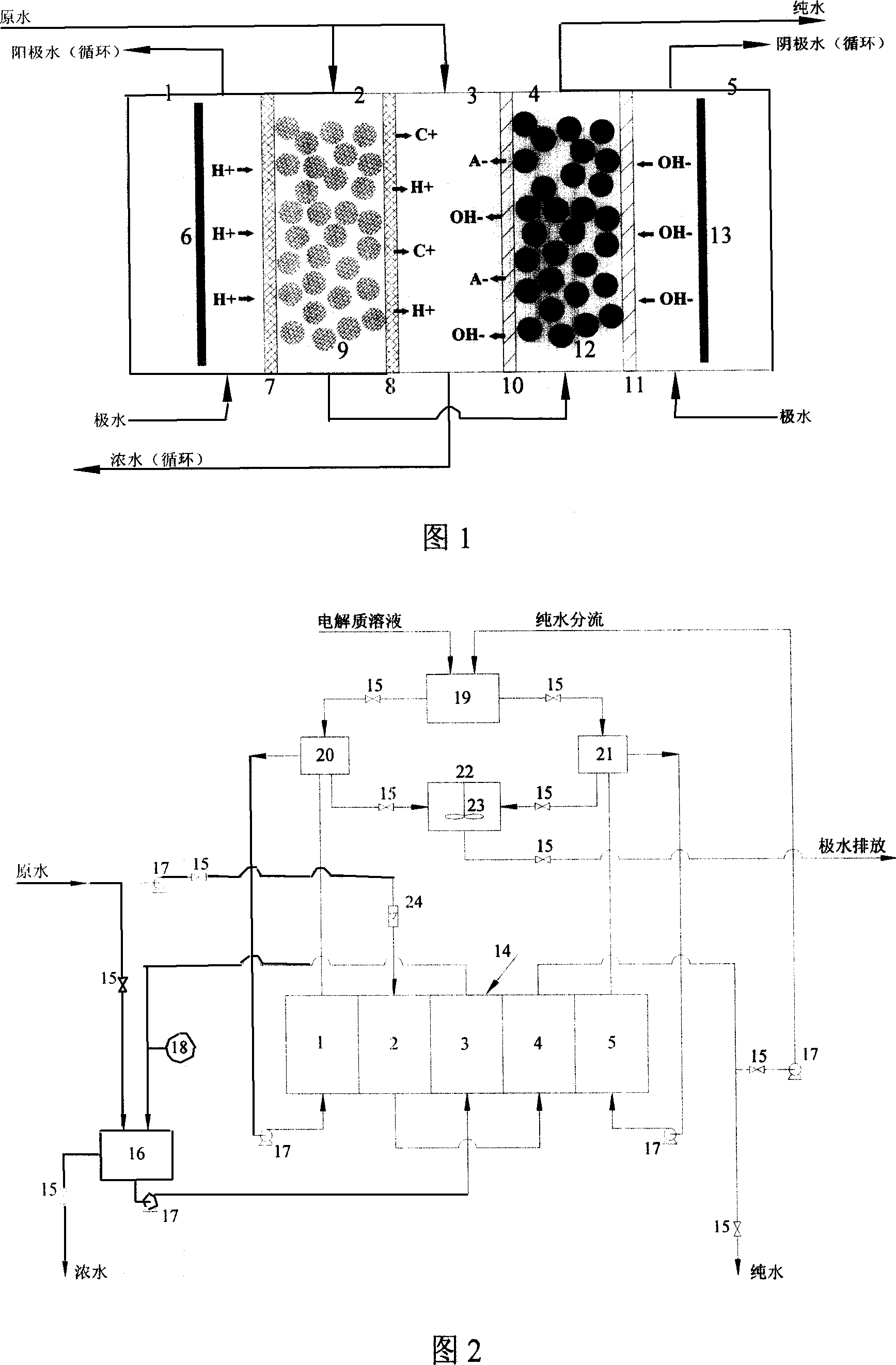

[0026] The five-compartment electrodeionization device shown in Figure 1 is used to produce pure water, and the process flow is shown in Figure 2. The anode is a titanium mesh electrode coated with ruthenium, and the cathode is a stainless steel mesh electrode. The anion and cation exchange resins are respectively D201 macroporous strongly basic styrene-based anion resin and D001 macroporous strongly acidic styrene-based cation resin. The cation resin is hydrogen type and the anion resin is hydroxide type. Anion and cation exchange membranes are domestic DF120 homogeneous anion exchange membrane and DF120 homogeneous cation exchange membrane respectively. The effective area of membrane and electrode is 150cm 2 , Membrane distance 0.8cm, electrode chamber thickness 1.6cm, the first dilute chamber and the second dilute chamber are filled with about 120ml of cationic and anion exchange resins respectively. Raw water is tap water after mechanical filtration. First, a small am...

Embodiment 2

[0028] The anion and cation exchange membranes in Example 2 are domestic heterogeneous anion and cation exchange membranes; the effective area of the membrane and the electrodes is expanded to 900cm 2 ; The first light chamber and the second light chamber are filled with about 720ml of cation and anion exchange resins respectively; the raw water is the plated parts cleaning water discharged from the nickel plating production line of the electroplating plant, which contains Ni 2+ About 50mg / L, SO 4 2- About 82mg / L, pH value about 6; 60V voltage is applied to both ends of the device electrodes; the rest of the device parts and water purification process are the same as in Example 1. Under the above operating conditions, the electrodeionization device operates continuously and stably for 240 hours, and the raw water treatment capacity is 1.5m 3 / h, Ni in fresh water 2+ Concentration lower than 0.05mg / L, Ni in concentrated water 2+ The amount can reach 4200mg / L, the current ...

Embodiment 3

[0030] The device, water purification process and operation steps of Example 3 are the same as those of Example 1, and the difference from Example 1 is that: Example 3 uses domestic heterogeneous anion and cation exchange membranes; the raw water is NO-containing 3 - 70mg / L, PO 4 3- 30mg / L water; extreme water is 25mg / L NaNO 3 solution; the concentrated water is recycled as fertilizer; the updated anode and anode water are discharged and mixed with raw water for reuse. The water inlet flow rate of the control device is 200L / h, and the resulting NO in the outlet water 3 - Concentration lower than 0.3mg / L, PO 4 3- The concentration is lower than 0.06mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com