Catalyst for production of methyl acetate through carbonylation of dimethyl ether and application thereof

A technology of methyl acetate and catalyst, which is applied in the direction of physical/chemical process catalyst, carbon monoxide or formate reaction preparation, molecular sieve catalyst, etc., and can solve problems such as easy deactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The preparation of embodiment 1 Na-EMT molecular sieve

[0033] According to the method in the document Synthesis of silica-rich faujasite using crown-ethers astemplates: F.Delprato et, ZEOLITES, 1990, VOl 10: 546, three samples were prepared, respectively denoted as A (after the crystallization was completed, rinse with cold water Chilling down to room temperature), B (after the crystallization is completed, move it out of the oven to cool to room temperature) and C (after the crystallization is complete, cool down to room temperature in the oven at a rate of 10°C / hour).

Embodiment 2

[0034] The characterization of embodiment 2 Na-EMT molecular sieve

[0035] The median diameter D of Na-EMT molecular sieve samples A, B and C were measured respectively 50 , and the results are shown in Table 1.

[0036] Table 1

[0037] Na-EMT molecular sieve number Median particle size D 50 (microns)

Embodiment 3

[0038] The preparation of embodiment 3 H-EMT molecular sieve catalyst samples

[0039] After the Na-EMT molecular sieve samples prepared in Example 1 were roasted at 550°C, 10 grams were taken respectively, exchanged three times with 0.5mol / L ammonium nitrate (2 hours / time), washed with deionized water, dried, and dried at 550 ℃ calcined for 4 hours, and then extruded to prepare a 20-40 mesh H-EMT molecular sieve catalyst sample.

[0040] The H-EMT molecular sieve catalyst samples prepared from Na-EMT molecular sieve samples A, B and C are respectively designated as sample 1 # , sample 2 # and sample 3 # .

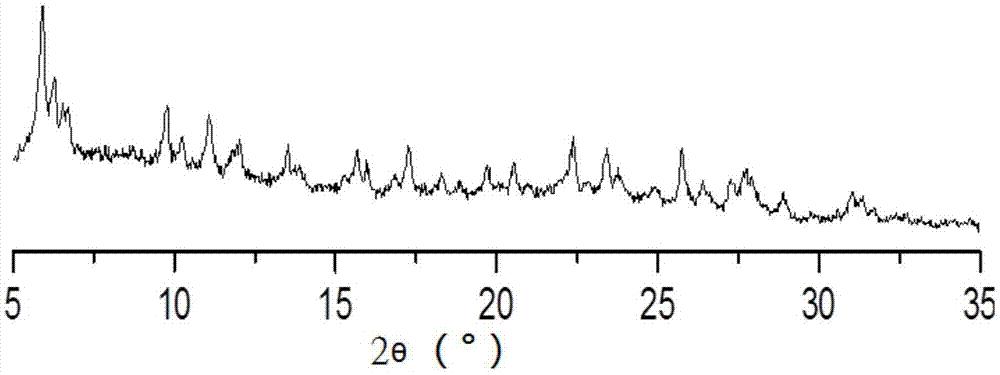

[0041] Adopt XRD to sample 1 respectively # , sample 2 # and sample 3 # The phase of the phase is characterized, and the typical representative is sample 1 # , the result is as figure 1 shown. Depend on figure 1 It can be seen that sample 1 # It is an acidic molecular sieve with EMT structure.

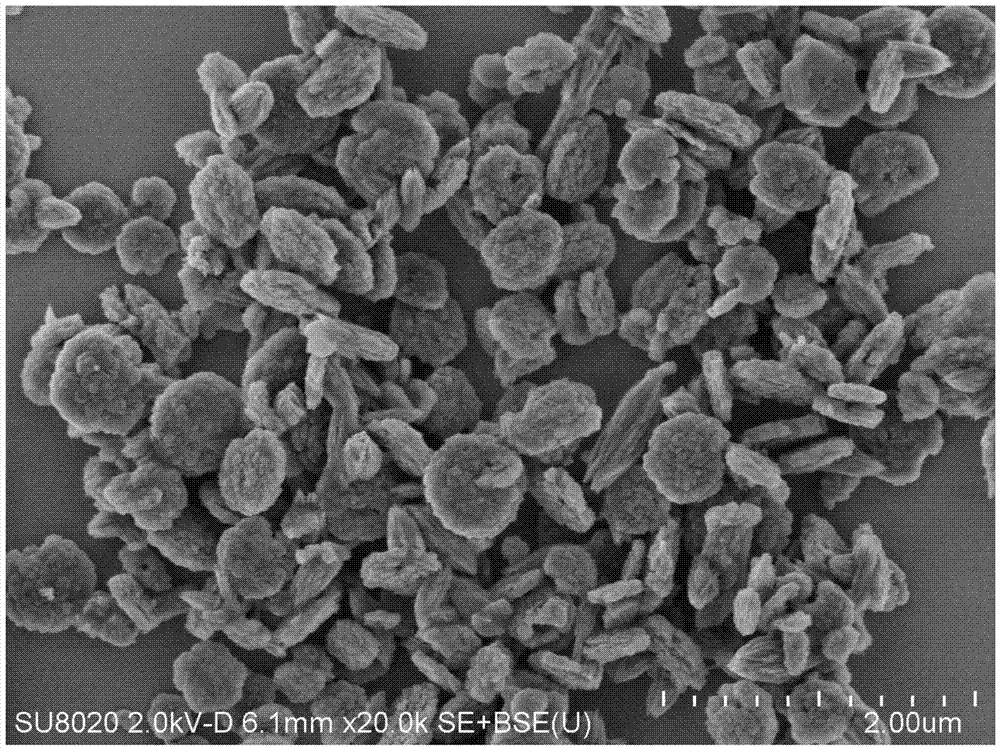

[0042] Sample 1 was examined by scanning electron microscopy# The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com