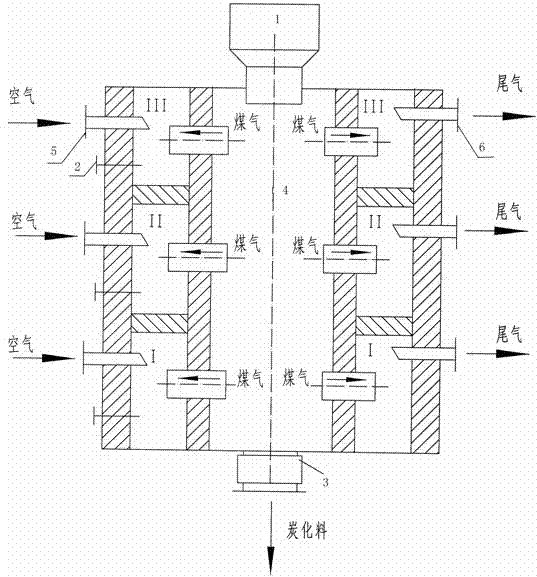

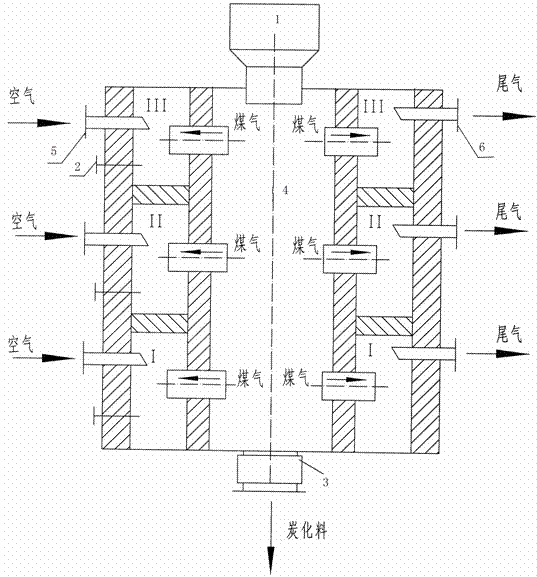

External heating biomass pyrolysis gasification furnace and method for preparing charcoal by continuous pyrolysis gasification

A technology of pyrolysis gasification and biomass, which is applied in the direction of carbonization furnace, biofuel, coke cooling, etc., can solve the problems that affect the yield and quality of finished charcoal, the labor intensity of workers, and the loss of biomass raw materials, etc., to achieve The device occupies less land, is easy to operate, and has the effect of precise control of material balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] An external heating biomass continuous pyrolysis gasification process. The 50±30 mm wood blocks are sent into the pyrolysis gasifier through the bin on the top of the pyrolysis gasifier. After preheating, the wood blocks enter the thermal In the pyrolysis section, the pyrolysis gas enters three independent combustion chambers through the gas overflow pipe on the furnace, and the combustion reaction temperature of the combustion chamber is controlled by precisely controlling the amount of air entering the combustion chamber, thereby precisely controlling the pyrolysis temperature to 750 °C. The tail gas after combustion reaction is recycled and emptied from the chimney, and the charcoal product after pyrolysis and dry distillation is discharged from the discharge port of the pyrolysis furnace after being cooled to 180°C.

[0048] The main technical parameters of charcoal products produced by an externally heated biomass continuous pyrolysis gasifier with an inner diameter...

Embodiment 2

[0058] An external heating biomass continuous pyrolysis gasification process. 0.5-5 mm wood chips are sent into the pyrolysis gasifier through the bin on the top of the pyrolysis gasifier. After preheating, the wood chips enter the pyrolysis and carbonization process. In the section, the pyrolysis gas enters three independent combustion chambers through the gas overflow pipe on the furnace, and the combustion reaction temperature of the combustion chamber is controlled by precisely controlling the amount of air entering the combustion chamber, so that the pyrolysis temperature is precisely controlled to 650°C. The tail gas after the combustion reaction is recycled and emptied from the chimney, and the charcoal product after pyrolysis and carbonization is cooled to 120°C and then discharged from the discharge port of the pyrolysis furnace.

[0059] The main technical parameters of charcoal products produced by an externally heated biomass continuous pyrolysis gasifier with an in...

Embodiment 3

[0069] A continuous pyrolysis and gasification process for externally heated biomass. The 1-10 mm fruit shells are sent into the pyrolysis gasification furnace through the bin on the top of the pyrolysis gasification furnace, and the wood chips enter the pyrolysis gasification furnace after preheating. In the dry distillation section, the pyrolysis gas enters three independent combustion chambers through the gas overflow pipe on the furnace, and the combustion reaction temperature of the combustion chamber is controlled by precisely controlling the amount of air entering the combustion chamber, thereby precisely controlling the pyrolysis temperature to 700°C. The tail gas after the combustion reaction is recycled and emptied from the chimney, and the charcoal product after pyrolysis and dry distillation is discharged from the discharge port of the pyrolysis furnace after being cooled to 170°C.

[0070] The main technical parameters of charcoal products produced by an externally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com