A method for vacuum degreasing of gel injection molded turbine blade ceramic mold

A technology of ceramic casting and gel injection moulding, applied in the field of rapid casting, can solve the problems of large gas generation, shell cracking, impact damage of blanks, etc. The effect of thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

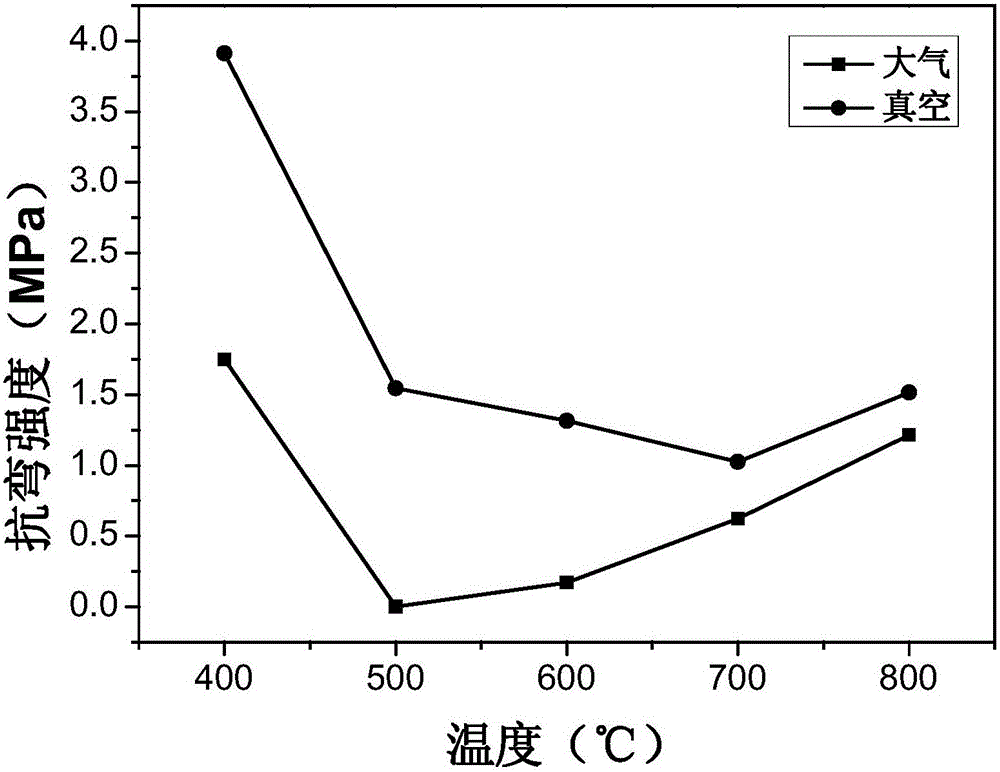

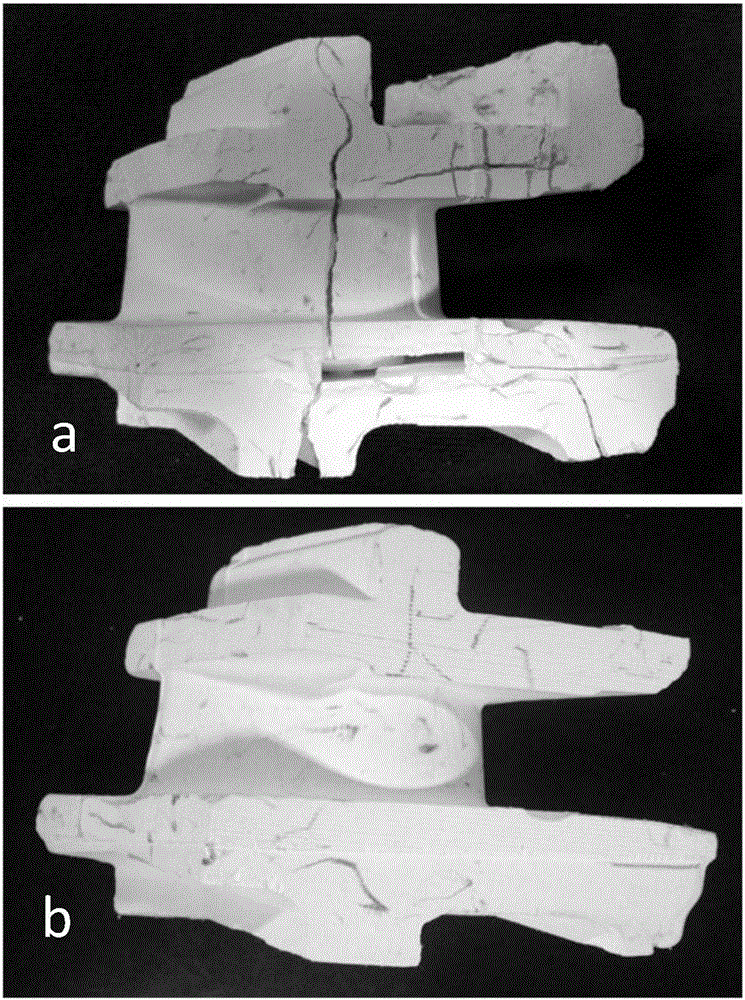

Problems solved by technology

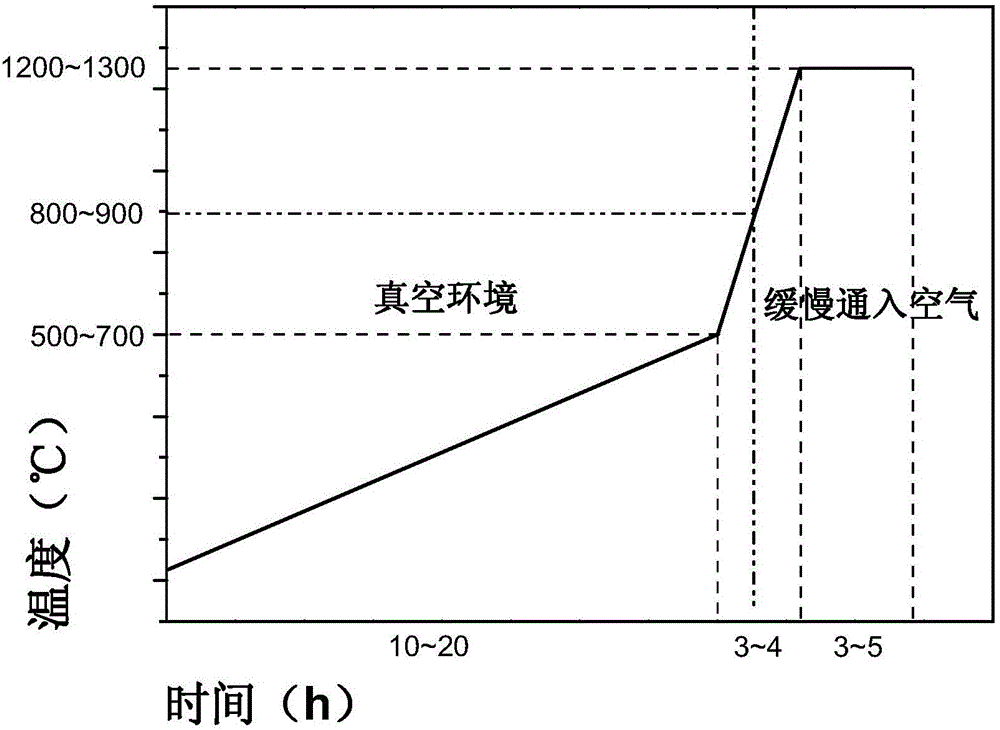

Method used

Image

Examples

Embodiment 1

[0034] (1) Use 3D modeling software (UG, ProE, etc.) to design the blade resin mold, import the CAD model data into the Magics layering software for layering processing, and carry out the hollowing out process inside the entity, and import the model layering data into the light-curing rapid prototyping equipment Make a hollow turbine blade resin mold, and the molding resin is SPRS8981 photosensitive resin.

[0035] (2) Prepare ceramic slurry based on gel injection molding process.

[0036] 2) Weigh 60% large particle size aluminum oxide alumina, 39% aluminum oxide, and 1% magnesium oxide according to the mass ratio, and stir and mix them evenly in a container to obtain powder; wherein, the particle size of large particle size alumina The particle size of small-particle-diameter alumina is 2-10 μm.

[0037] 2) Dissolve the organic monomer acrylamide AM and the crosslinking agent N,N'-methylenebisacrylamide MBAM in deionized water at a mass ratio of 20:1, then add a dispersant ...

Embodiment 2

[0052] (1) Use three-dimensional modeling software, such as UG, ProE, to design the blade resin mold, import the CAD model data into the Magics layering software for layering processing, and carry out the internal hollowing out of the blade resin mold after layering processing, and layer the model The data is imported into the photocuring rapid prototyping equipment to make the hollow turbine blade resin mold, and the molding resin is SPRS8981 photosensitive resin.

[0053] (2) Prepare ceramic slurry based on gel injection molding process:

[0054] 2) Weigh 65% large particle size aluminum oxide alumina, 30% aluminum oxide, and 5% magnesium oxide according to the mass ratio, and stir and mix them evenly in a container to obtain powder; wherein, the particle size of large particle size alumina The particle size of small-particle-diameter alumina is 2-10 μm.

[0055] 2) Dissolve the organic monomer methacrylamide and the crosslinking agent methyl acryl acrylate into deionized w...

Embodiment 3

[0065] (1) Use three-dimensional modeling software, such as UG, ProE, to design the blade resin mold, import the CAD model data into the Magics layering software for layering processing, and carry out the internal hollowing out of the blade resin mold after layering processing, and layer the model The data is imported into the photocuring rapid prototyping equipment to make the hollow turbine blade resin mold, and the molding resin is SPRS8981 photosensitive resin.

[0066] (2) Prepare ceramic slurry based on gel injection molding process:

[0067] 2) Weigh 70% large particle size aluminum oxide alumina, 26% aluminum oxide, and 4% magnesium oxide by mass percentage, and stir and mix them evenly in a container to obtain powder; wherein, the particle size of large particle size alumina The particle size of small-particle-diameter alumina is 2-10 μm.

[0068] 2) Dissolve the organic monomer methylolacrylamide and the crosslinking agent N,N'-methylenebisacrylamide MBAM in deioniz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com