Preparation method of rubber composition and rubber composition

A rubber composition and floor technology, which is applied in building construction, construction, fire rescue and other directions, can solve the problems of poor waterproofness at seams and poor flame retardancy of rubber floors, and achieves preventing the spread of flames, increasing the anti-skid effect, The effect of expanding the fire area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

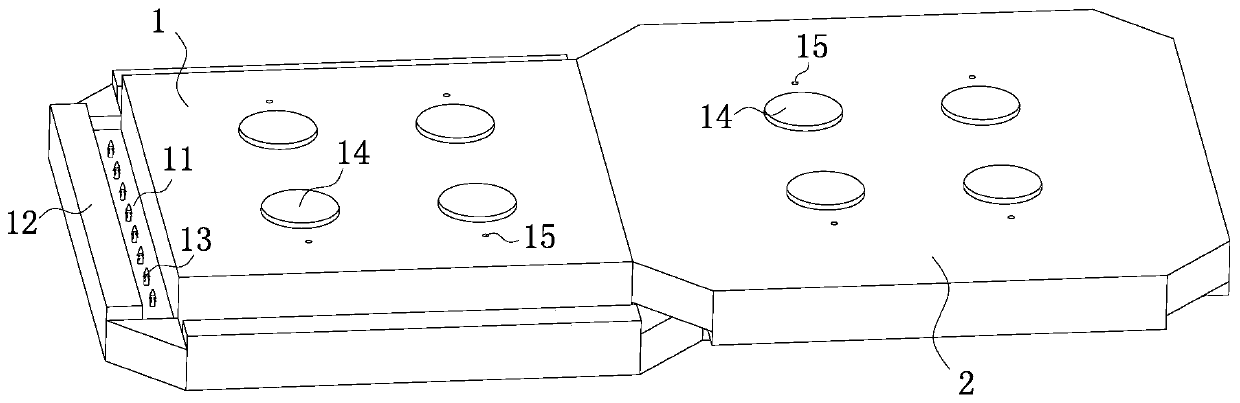

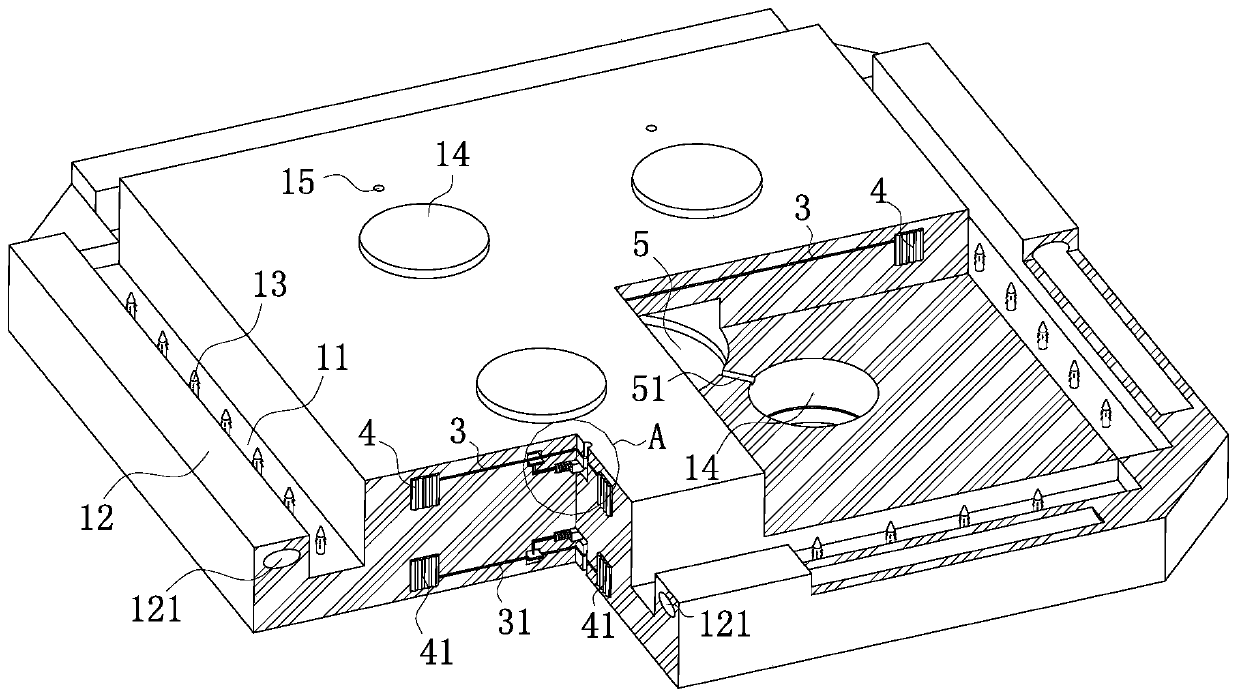

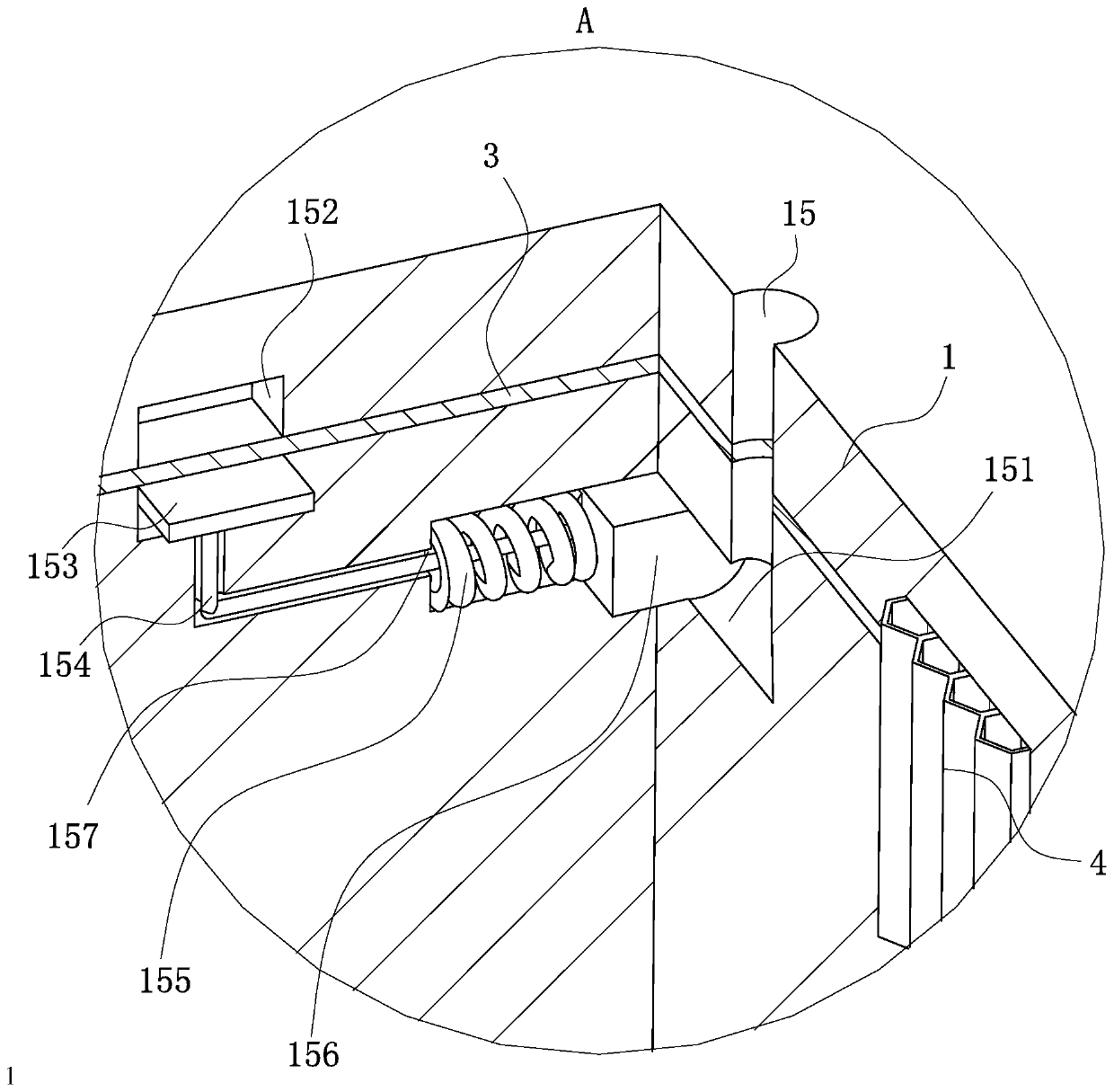

[0031] As an embodiment of the present invention, an upper filling cavity 4 and a lower filling cavity 41 are opened in the floor unit-1; the upper filling cavity 4 and the lower filling cavity 41 are symmetrically distributed up and down inside the floor unit-1; The upper filling cavity 4 is in the shape of a well; the lower filling cavity 41 is in the shape of a well; the upper filling cavity 4 is filled with expandable graphite; the lower filling cavity 41 is filled with expandable graphite; the floor unit-1 An upper metal net 3 and a lower metal net 31 are installed inside; the upper metal net 3 and the lower metal net 31 are symmetrically distributed up and down inside the floor unit one 1; the upper metal net 3 passes through the upper filling cavity 4; the upper The metal mesh 3 passes through the action cavity 152 in the upper part of the floor unit one 1, and the upper metal mesh 3 is in close contact with the bimetal sheet 153; the lower metal mesh 31 passes through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com