Novel sealing structure for gallium arsenide crystal growth

A technology of crystal growth and sealing structure, which is applied in the directions of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of inconvenient operation of sealing materials and the need for improvement of sealing effect, and achieve the advantages of connection, convenient operation and firm sealing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

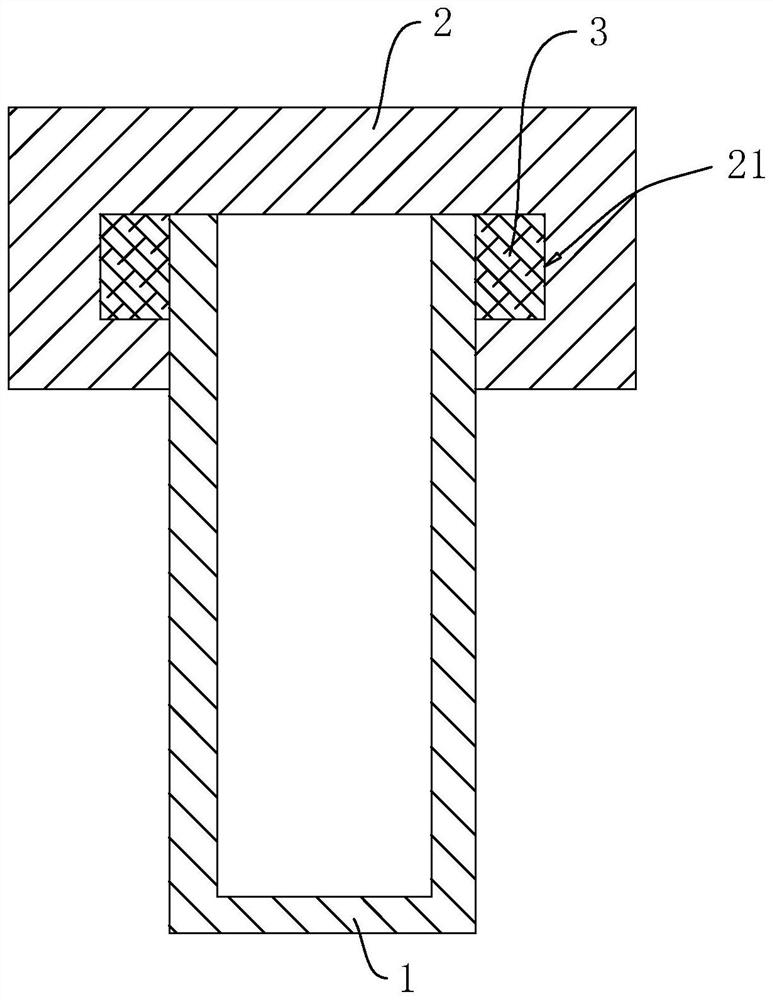

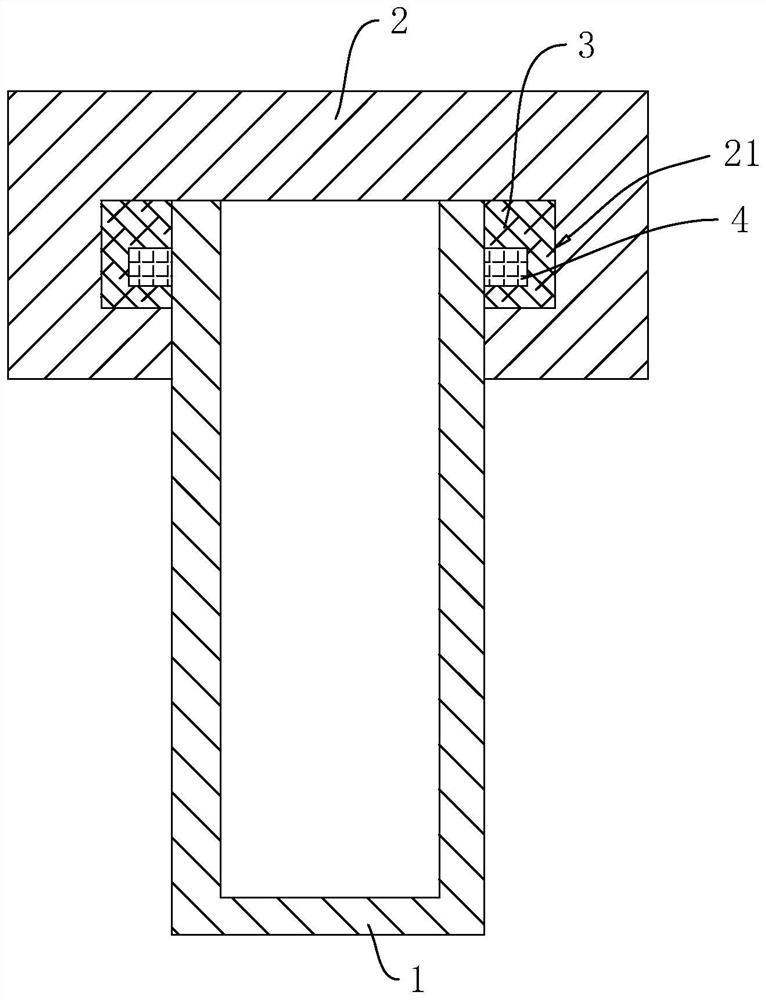

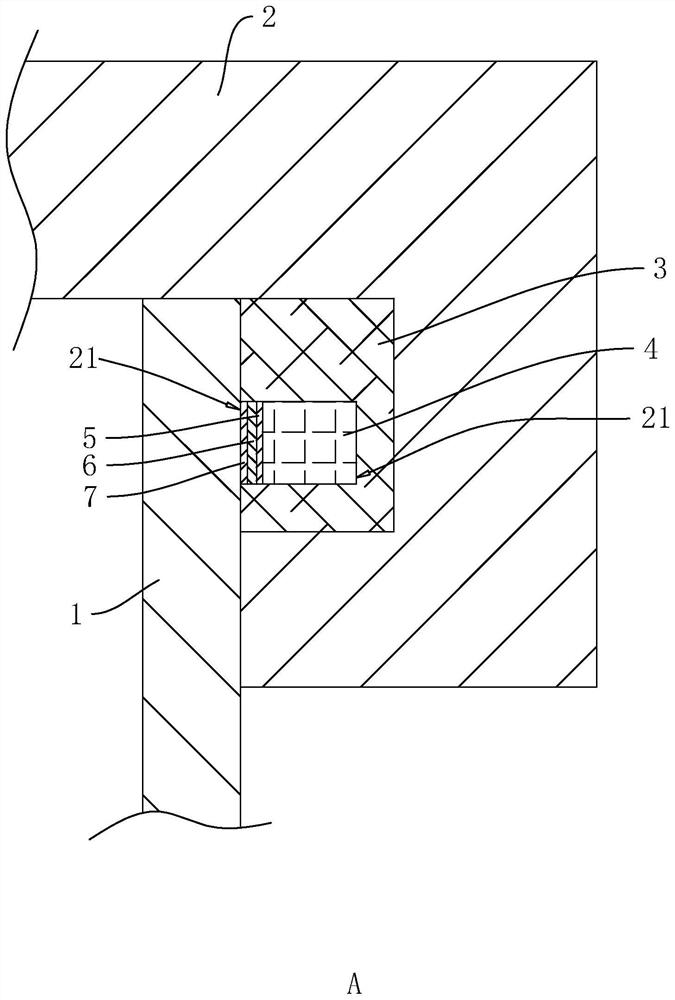

[0035] A novel sealing structure for gallium arsenide crystal growth, comprising a quartz tube 1 and a quartz cap 2, the inner wall of the lower end of the quartz cap 2 is provided with internal threads and the outer wall of the quartz tube 1 is provided with threaded holes, so that the quartz cap 2 and the quartz tube are The threaded connection of 1, the side of the quartz cap 2 close to the quartz tube 1 is provided with an accommodating groove 21 along its peripheral surface, the accommodating groove 21 is located between the top of the quartz cap 2 and the inner thread, and the accommodating groove 21 is filled with expanded graphite-basalt fiber composite. The cloth 3, in this way, not only realizes the threaded connection between the quartz cap 2 and the quartz tube 1, the operation is more convenient, and the filled composite cloth 3 has a certain filling performance, which can be fitted with the quartz tube 1, and the expanded graphite expands during the later growth pr...

Embodiment 2

[0039] A novel sealing structure for gallium arsenide crystal growth is carried out according to the method in Example 1, except that the expanded graphite-basalt fiber composite cloth 3 is prepared by the following method:

[0040] The basalt fiber cloth was immersed in water dispersed with expanded graphite for 30 minutes, and the mass ratio of expanded graphite to water was 20:1, and then dried at 80 °C for 30 minutes.

Embodiment 3

[0042] A novel sealing structure for gallium arsenide crystal growth is carried out according to the method in Example 1, except that the expanded graphite-basalt fiber composite cloth 3 is prepared by the following method:

[0043] The basalt fiber cloth was immersed in water dispersed with expanded graphite for 30 minutes, and the mass ratio of expanded graphite to water was 18:1, and then dried at 70 °C for 35 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com