Water-based adhesive for high-temperature-resistant graphene manganese-rich lithium ion battery diaphragm

A water-based adhesive, manganese-rich lithium technology, applied in the direction of non-polymer adhesive additives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problem that adhesives do not have high temperature resistance, Adhesive peeling, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This embodiment is a temperature-resistant modified polyurethane emulsion, and the preparation method includes the following steps

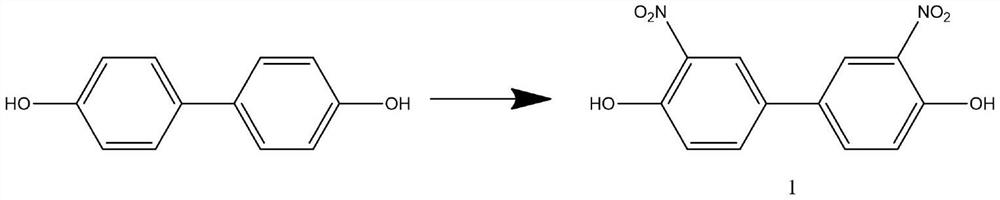

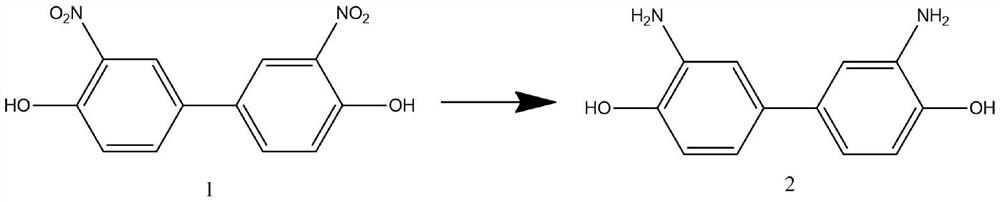

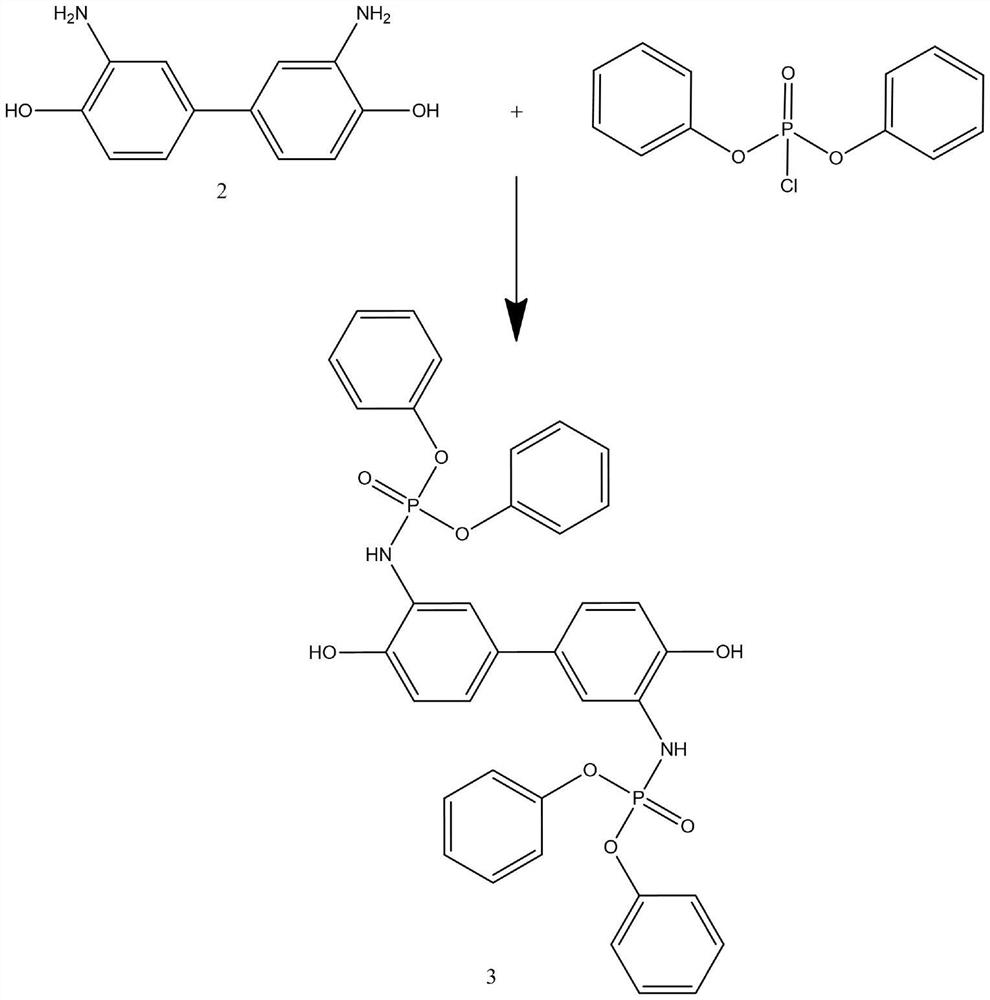

[0046] A1: Add 0.1mol of 4,4'-dihydroxybiphenyl and 15mL of ethyl acetate into a three-necked flask equipped with a stirrer, a thermometer and a constant pressure dropping funnel, at a temperature of 0°C and a stirring rate of 200r / min Stir until 4,4'-dihydroxybiphenyl is completely dissolved under conditions, and then add 60 mL of concentrated nitric acid with a mass fraction of 65% and a concentrated sulfuric acid with a mass fraction of 95% dropwise while stirring. The resulting mixed acid was controlled at a drop rate of 1 drop / s. After the dropwise addition, the temperature was raised to 10 °C and the reaction was continued for 4 hours. After the reaction, the reaction product was vacuum filtered, and the filter cake was washed twice with distilled water. After that, it was placed in a vacuum drying oven and dried for 3 hours at a tem...

Embodiment 2

[0054] This embodiment is a temperature-resistant modified polyurethane emulsion, and the preparation method includes the following steps

[0055] A1: Add 0.1mol of 4,4'-dihydroxybiphenyl and 20mL of ethyl acetate into a three-necked flask equipped with a stirrer, a thermometer and a constant pressure dropping funnel, at a temperature of 5°C and a stirring rate of 300r / min Stir until 4,4'-dihydroxybiphenyl is completely dissolved, and then add 80 mL of concentrated nitric acid with a mass fraction of 68% and a concentrated sulfuric acid with a mass fraction of 98% dropwise while stirring to mix at a mass ratio of 1:3. The resulting mixed acid was controlled at a drop rate of 2 drops / s. After the dropwise addition, the temperature was raised to 15°C and the reaction was continued for 6 hours. After the reaction, the reaction product was vacuum filtered, and the filter cake was washed with distilled water 3 times. After that, it was placed in a vacuum drying oven and dried for 5...

Embodiment 3

[0063] The present embodiment is a preparation method of a high temperature resistant graphene manganese-rich lithium ion battery separator water-based adhesive, comprising the following steps:

[0064] Step 1: Weigh 70 parts of temperature-resistant modified polyurethane emulsion, 10 parts of nano-iron tetroxide powder, 0.8 parts of antioxidant, 0.5 part of defoamer, and 1.5 parts of thickener according to weight parts from Example 1 , 1.0 part of silane coupling agent and 0.5 part of isocyanate curing agent, for standby; antioxidant is antioxidant 1076, defoamer is silicone defoamer, thickener is methyl cellulose, silane coupling agent It is silane coupling agent KH-550, and the isocyanate curing agent is xylylene diisocyanate;

[0065] Step 2: stirring and mixing the temperature-resistant modified polyurethane emulsion, nano-ferric oxide powder, antioxidant, defoaming agent, thickening agent and silane coupling agent for 1 h under the condition of a stirring speed of 2000 r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com