A kind of spandex fiber with high uniformity and easy bonding and preparation method thereof

A spandex fiber, easy-bonding technology, applied in the direction of fiber chemical characteristics, rayon manufacturing, conjugated synthetic polymer rayon, etc., can solve the problems of fiber breakage, uneven force on the surface and inner layers, etc., and achieve elastic recovery High stability, high fiber uniformity, uniform fusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] A kind of preparation method of high uniformity and easy bonding spandex fiber of the present invention comprises the following steps:

[0020] 1) Mix polyurethane urea, 4.5% to 15% compatibilizer, and 0.5% to 5.0% flow promoter in an organic solvent to obtain polyurethane solution A ;

[0021] 2) The weight percentage of each component is respectively 5.0% to 20% of polyurethane urea, 60% to 90% of thermoplastic polyurethane, 4.5% to 15% of compatibilizer, and 0.5% to 5.0% of flow promoter in an organic solvent Mix well to obtain polyurethane solution B;

[0022] 3) The polyurethane solution A and the polyurethane solution B are respectively passed through the inner layer feed port and the outer layer feed port of the composite component, and the high uniformity and easy-bonding spandex fibers are prepared by dry spinning technology.

[0023] The compatibilizer is a compound containing carbamate groups, the mass fraction of carbamate groups contained in it is ≥10.0%;...

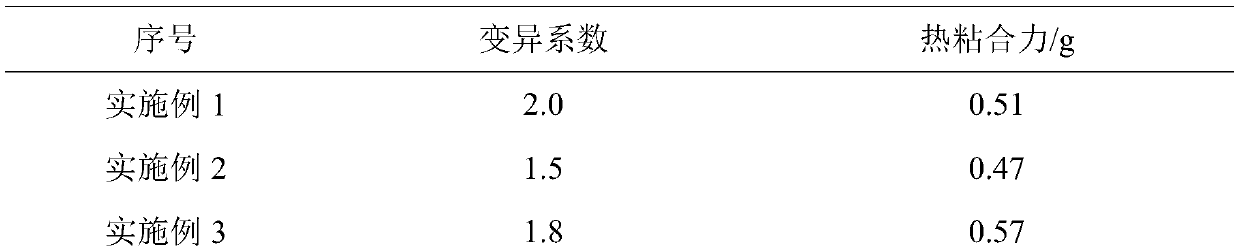

Embodiment 1

[0030] The preparation of polyurethane solution A: the 2-(2'-hydroxyl of 86.5% polyurethane urea, 10% compatibilizer, 2% flow promoter, 0.5wt% titanium dioxide, 0.5wt% by weight of each component -3', 5'-di-tert-butylphenyl)-benzotriazole), 0.3wt% bis(N,N-dimethylhydrazideamino4-phenyl)methane, 0.20wt% stearin Magnesium acid is mixed evenly in N,N-dimethylacetamide to form a solid content of 35% inner layer stock solution; the preparation of polyurethane solution B (outer layer stock solution): the polyurethane urea with 10% by weight of each component , 76.5% thermoplastic polyurethane, 10% compatibilizer, 2% flow promoter, 0.5wt% titanium dioxide, 0.5wt% 2-(2'-hydroxy-3', 5'-di-tert-butylphenyl )-benzotriazole), 0.3wt% bis(N,N-dimethylhydrazideamino-4-phenyl)methane, 0.20wt% magnesium stearate in N,N-dimethylacetamide Mix evenly to form an outer layer stock solution with a solid content of 35%; pass the inner layer stock solution and the outer layer stock solution through t...

Embodiment 2

[0035] Composite spandex was prepared in the same manner as in Example 1, except that the selected compatibilizer was polyurethane with a mass fraction of urethane groups of 15%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com