A kind of preparation method and device for metal composite board

A metal clad plate and substrate technology, applied in metal rolling, metal rolling, metal processing equipment and other directions, can solve the problems of interface oxidation inclusion, reduce the composite strength of clad plates, etc., to enhance the composite strength, improve performance, eliminate interface Effects of defects and internal residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

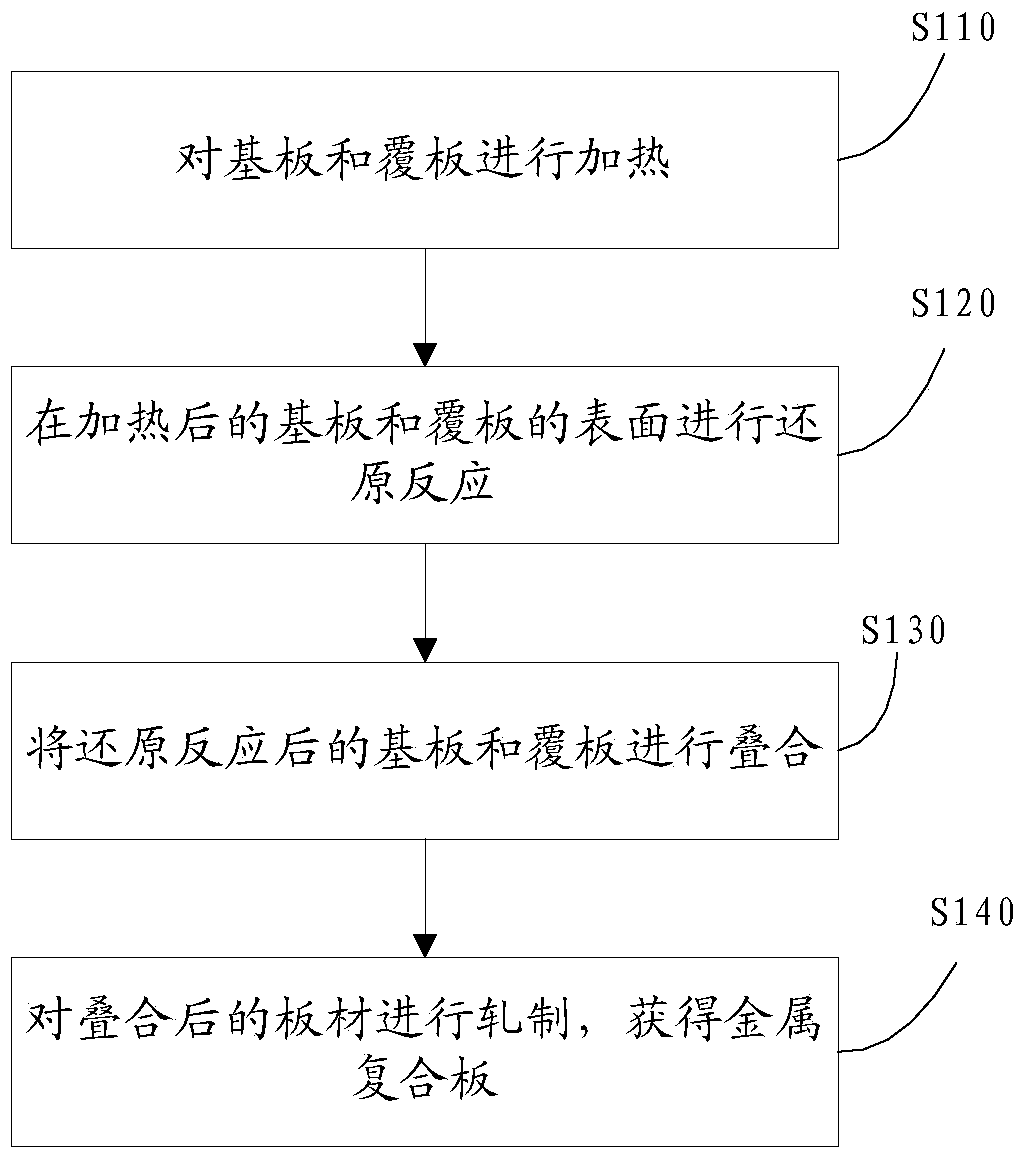

[0034] see figure 1 , the preparation method for the metal composite panel provided by the embodiment of the present invention includes:

[0035] Step S110: heating the substrate and the superstrate;

[0036] To illustrate this step, step S110 specifically includes:

[0037] The substrate and the superstrate are heated by a heating device.

[0038] What needs to be explained here is that the embodiments of the present invention can freely choose isothermal heating or non-isothermal heating for the substrate and the cover plate according to the needs, which satisfies the heating requirements of various materials when they are combined, and is therefore suitable for use between various materials. Combination improves the practicability of the embodiments of the present invention.

[0039] In this embodiment, the substrate and the superstrate are heated to 700-1200°C.

[0040] In order to ensure that the size of the plate is regular, the length and width are consistent, and t...

Embodiment 2

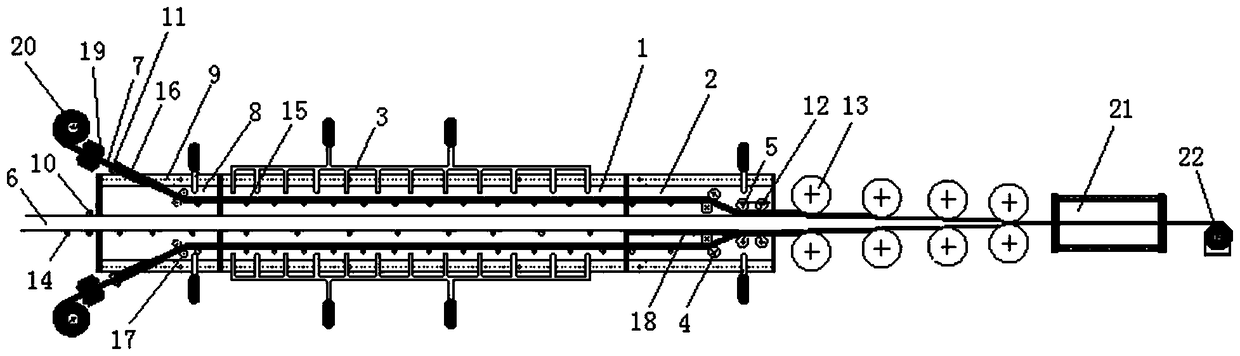

[0067] Adopt this method to prepare the steps of aluminum-carbon steel single-sided composite panel as follows:

[0068] 1. Substrate processing and heating: The substrate is prepared by Q235, and the substrate is machined to make the substrate size 90mm×900mm×8000mm. After the processing is completed, the surface is cleaned to make it clean and free of rust and oil. Then the substrate is sent into the heating furnace to be heated to 1100°C, and then it is taken out of the furnace for high-pressure water descaling treatment.

[0069] 2. Processing of clad metal coils: Uncoil and cut pure aluminum coils with a thickness of 10mm to make the width 900mm; then use a wire brush to clean the oxide layer on the surface of the aluminum coils, roughen the surface of the aluminum coils and take them up for later use.

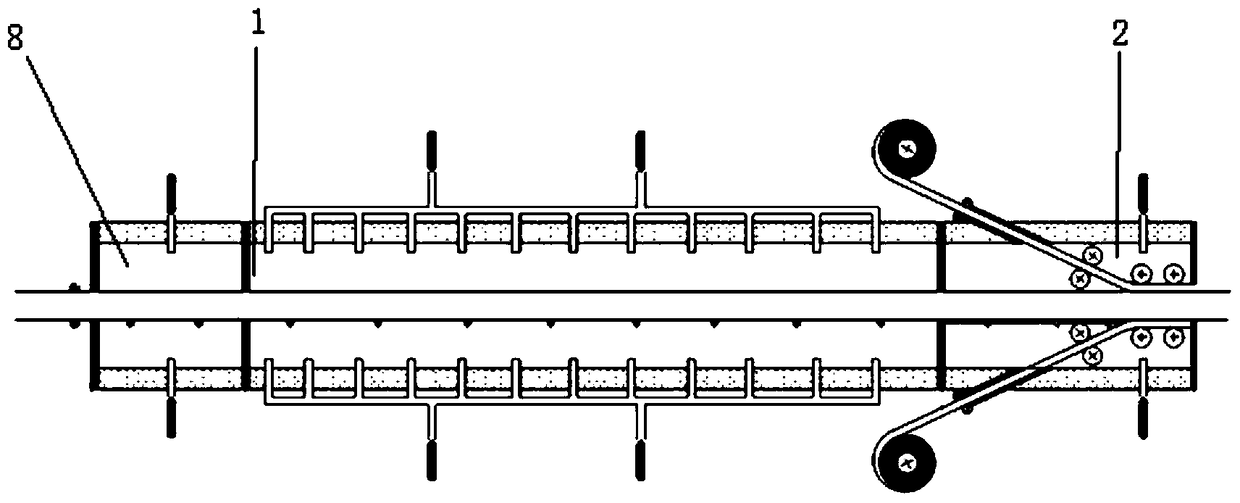

[0070] 3. Base plate and cladding plate heating and scale reduction: after the base plate is heated and descaled, it is sent into the reduction furnace through the roller...

Embodiment 3

[0075] Adopt this method to prepare the step of copper-aluminum single-sided composite board as follows:

[0076] 1. Coil processing of metal raw materials: Uncoil and cut the pure copper coil with a thickness of 15mm and the pure aluminum coil with a thickness of 15mm respectively, so that the width of the pure copper coil and pure aluminum coil is 950mm; then use a wire brush to clean the two coils. remove the oxide layer on the surface of each strip, roughen the surface and take it up for later use.

[0077] 2. Heating of metal raw coils and reduction of scale: heat two coils through heating equipment, and introduce them into the reduction furnace through the introduction device. Next, the high-temperature reducing gas is passed into the reduction furnace, so that the high-temperature reducing gas and the residual oxides on the surfaces of the two coils undergo a reduction reaction. Among them, the reducing gas is H 2 Gas, the gas temperature is 750°C.

[0078] 3. Lamina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com