A method and device for preparing a metal composite panel

A technology of metal clad plate and clad slab, which is applied in the direction of metal rolling, metal rolling, metal processing equipment, etc., and can solve problems such as inability to continue clad rolling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

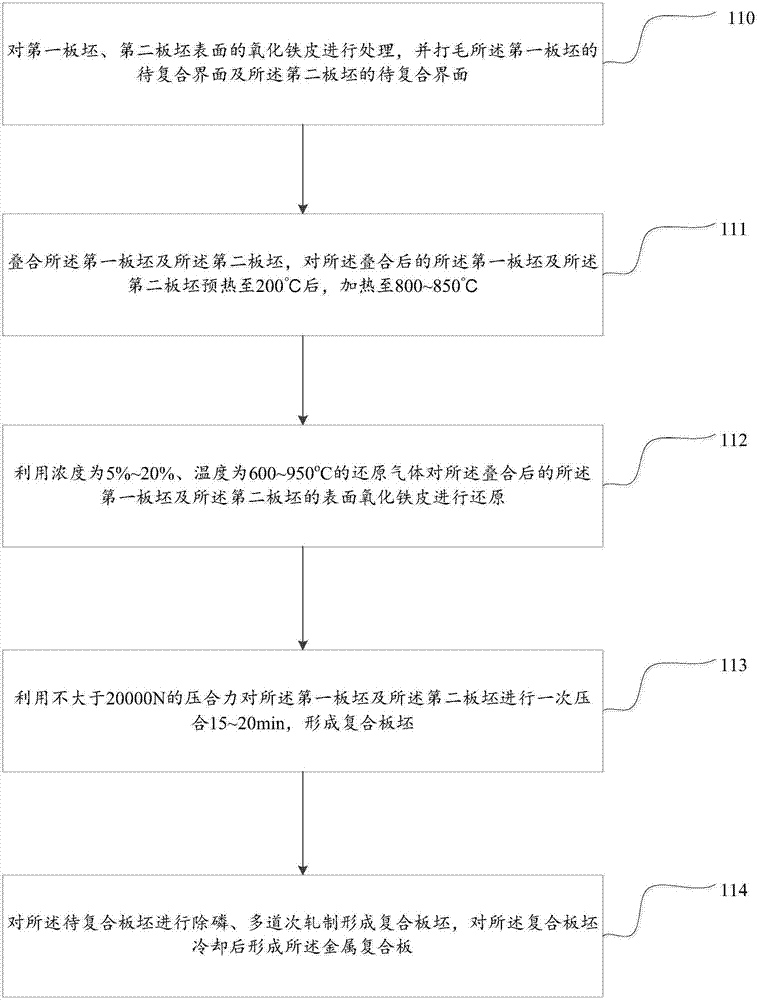

[0050] This embodiment provides a method for preparing a metal composite panel, such as figure 1 As shown, the method includes the following steps:

[0051] Step 110, treating the oxide scale on the surface of the first slab and the second slab, and roughening the interface to be combined of the first slab and the interface to be combined of the second slab.

[0052] In this step, the first slab is placed on the first roller table, the first roller table is provided with a first brush roller and a first sealing groove, and the first slab is brushed off by using the first brush roller and the first sealing groove. The oxide scale of the interface to be compounded of the first slab, and roughening the interface to be compounded of the first slab.

[0053] The second slab is placed on the second roller table, the second roller table is provided with a second brush roller and a second sealing groove, and the second brush roller and the second sealing groove are used to brush off ...

Embodiment 2

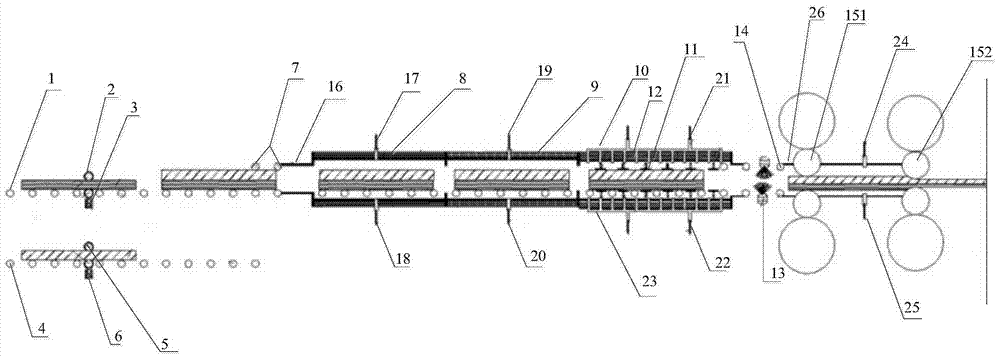

[0068] Corresponding to Embodiment 1, this embodiment also provides a device for preparing a metal plate, such as figure 2 As shown, the device includes: a first roller table 1, a first brush roller 2, a first sealed water tank 3, a second roller table 4, a second brush roller 5, a second sealed water tank 6, a billet inlet guide roller 7, Preheating furnace 8, heating furnace 9, reduction furnace 10, high-temperature multi-head press 11, heater 12, high-pressure water dephosphorization machine 13, rolling mill entrance guide roller 14, rolling mill 15; among them,

[0069] The first roller table 1 is provided with a first brush roller 2 and a first sealing groove 3. When the first slab runs on the first roller table 1, the first brush roller 2 and the first A sealing groove 3 is used for brushing off the iron scale on the interface of the first slab to be compounded, and roughening the interface of the first slab to be compounded. The first brush roll 2 includes two.

[00...

Embodiment 3

[0089] In order to better understand the technical solutions of the present invention, this embodiment further describes the present invention with reference to practical applications.

[0090] When adopting the method provided by the invention to prepare carbon steel-carbon steel clad plate, concrete implementation process is as follows:

[0091] First, the first plain carbon steel slab is placed on the first roller table, the first roller table is provided with the first brush roller and the first sealing groove, and the first brush roller and the first sealing groove are used to brush off the The oxide scale on the interface to be compounded of the first common carbon steel slab, and roughening the interface to be compounded on the first common carbon steel slab.

[0092] Place the second ordinary carbon steel slab on the second roller table, the second roller table is provided with a second brush roller and a second sealing groove, and use the second brush roller and the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com