Method and device for rolling metal composite strip

A metal clad plate and strip technology, applied in metal rolling, metal rolling, metal processing equipment and other directions, can solve the problems of continuous online production of metal clad plates and strips, interface oxidation, affecting the composite effect, etc., and achieve the effect of atomic diffusion The effect of obvious, high interface bonding strength and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

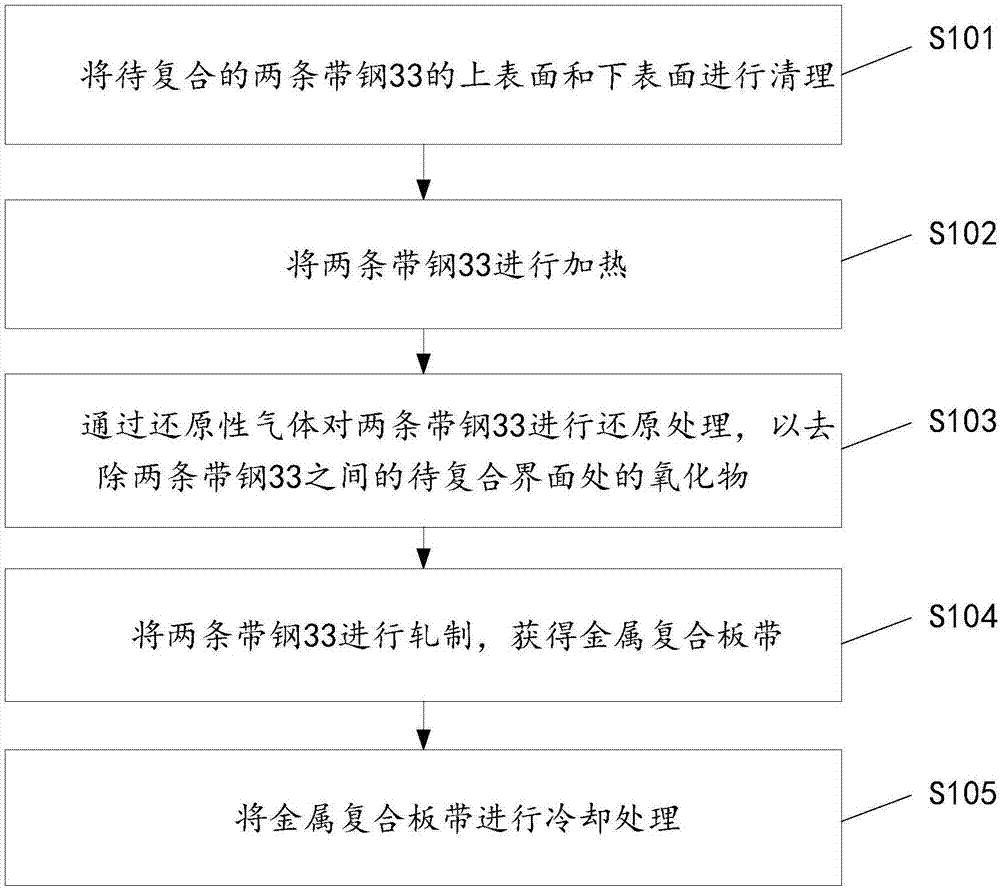

[0059] This embodiment provides a method for rolling metal clad strips, such as figure 1 shown, including:

[0060] Step S101: cleaning the upper and lower surfaces of the two steel strips 33 to be compounded.

[0061] specific items, such as figure 2 As shown, the two steel strips 33 to be compounded include: a cladding steel strip located above and a base strip steel located below. For example, the cladding strip is a stainless steel coil with a thickness of 15 mm, a width of 1500 mm, and a length of 1500 meters, and the base strip is a common carbon steel Q345 coil with a thickness of 15 mm, a width of 1500 mm, and a length of 1500 meters.

[0062] Specifically, the step S101 includes: placing two steel coils equal in length and width to be compounded on two uncoilers 1 for uncoiling, respectively deriving two steel strips 33, and using 3 straightening machines to The two steel strips 33 are leveled, and then the oxides (that is: scale) on the upper and lower surfaces o...

Embodiment 2

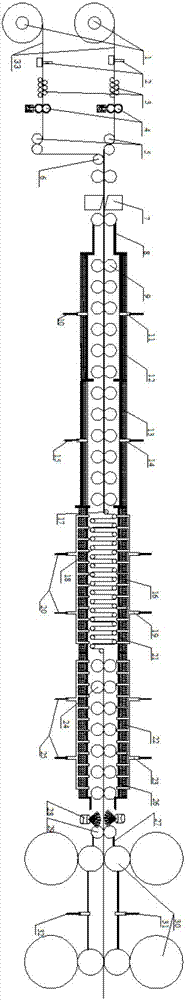

[0074] Based on the same inventive concept, the present invention provides a device for rolling metal composite strips, comprising:

[0075] A cleaning mechanism is used to clean the upper and lower surfaces of the two steel strips to be compounded;

[0076] The preheating furnace 12 is connected with the upsetting press 7, and is used for preheating the two steel strips 33;

[0077] The heating furnace 13 is connected with the preheating furnace 12, and is used to heat two steel strips 33, wherein coke is laid under the hearth rollers of the preheating furnace and the heating furnace;

[0078] Reduction furnace 16, connected with heating furnace 13, is used to carry out reduction treatment to two steel strips 33, to remove the oxide (that is: iron oxide scale) at the interface to be compounded between two steel strips 33;

[0079] The reduction heating furnace 22 is connected with the reduction furnace 16, and is used for rapidly heating the two steel strips 33;

[0080] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com