Cold spraying forming method of Cu-Cr-Nb series alloy

A cu-cr-nb, cold spray technology, applied in pressure inorganic powder coating and other directions, can solve the problems of difficult to effectively inhibit the efficient production of Cr2Nb, limit the application and promotion of materials, and the growth of Nb phase particles, so as to eliminate interface defects. , Coating thickness is not limited, the effect of tissue optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

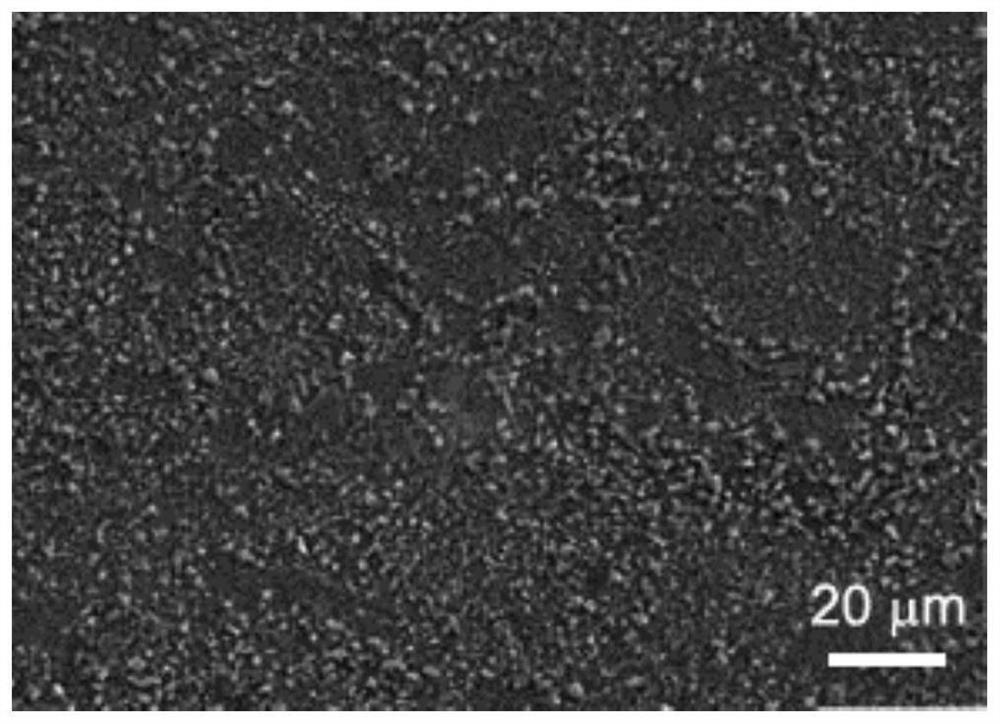

Image

Examples

Embodiment 1

[0024] The Cu-Cr-Nb series alloy cold spray preparation method of this embodiment includes the following steps:

[0025] (1) The atomic percentage composition is selected as Cu-4at.%Cr-2at.%Nb, the particle size is 25μm, Cr 2 Powders with Nb phase size less than 5μm were dried in a vacuum drying oven at 80°C for 30min to obtain cold spray powder raw materials; electrolytic copper plates treated by sandblasting after cold rolling were selected as the base material, and the base material was fixed on a rotating shaft with a speed of 120rpm superior.

[0026] Step 2, spraying the Cu-Cr-Nb powder onto the base material by using a cold spraying device to obtain a Cu-Cr-Nb sprayed layer. The process parameters of cold spraying are: the carrier gas is compressed air, the carrier gas pressure is 3MPa, the preheating temperature is 420℃, the distance between the surface of the base material and the nozzle outlet of the spray gun is 50mm, and the spray gun moves up and down at a moving...

Embodiment 2

[0030] The Cu-Cr-Nb series alloy cold spray preparation method of this embodiment includes the following steps:

[0031] (1) Select the atomic percentage composition as Cu-8at.%Cr-4at.%Nb, the particle size is 50μm, Cr 2 The powder with Nb phase size of 2-5μm was dried in a vacuum drying oven at 90 °C for 20 minutes to obtain the cold spray powder raw material; the electrolytic copper cylinder after cold rolling and sandblasting was used as the base material, and the base material was fixed at 150rpm. on the axis of rotation.

[0032] Step 2, spraying the Cu-Cr-Nb powder onto the base material by using a cold spraying device to obtain a Cu-Cr-Nb sprayed layer. The process parameters of cold spraying are: the carrier gas is nitrogen, the carrier gas pressure is 5MPa, the preheating temperature is 450℃, the distance between the surface of the base material and the nozzle outlet of the spray gun is 40mm, and the spray gun moves up and down at a moving speed of 6mm / s.

[0033] S...

Embodiment 3

[0036] The Cu-Cr-Nb series alloy cold spray preparation method of this embodiment includes the following steps:

[0037] (1) Select the atomic percentage composition as Cu-6at.%Cr-3at.%Nb, the particle size is 40μm, Cr 2 The powder with Nb phase size of 4-8 μm was dried in a vacuum drying oven at 85 °C for 30 minutes to obtain the cold spray powder raw material; the electrolytic copper plate after cold rolling and sandblasting was used as the base material, and the base material was fixed at 100 rpm. on the axis of rotation.

[0038] Step 2, spraying the Cu-Cr-Nb powder onto the base material by using a cold spraying device to obtain a Cu-Cr-Nb sprayed layer. The process parameters of cold spraying are: the carrier gas is argon, the carrier gas pressure is 4MPa, the preheating temperature is 480℃, the distance between the surface of the base material and the nozzle outlet of the spray gun is 45mm, and the spray gun moves up and down at a moving speed of 4mm / s.

[0039] Step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com