Regeneration method for reducing ignition loss of water-washing casting ceramsite sand

A technology of ceramsite sand and ignition loss, which is applied to casting molding equipment, cleaning/processing machinery of casting mold materials, manufacturing tools, etc., can solve the problems of high energy consumption, poor drying uniformity, etc., and achieve high removal rate , reduce energy consumption, reduce the effect of burning loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

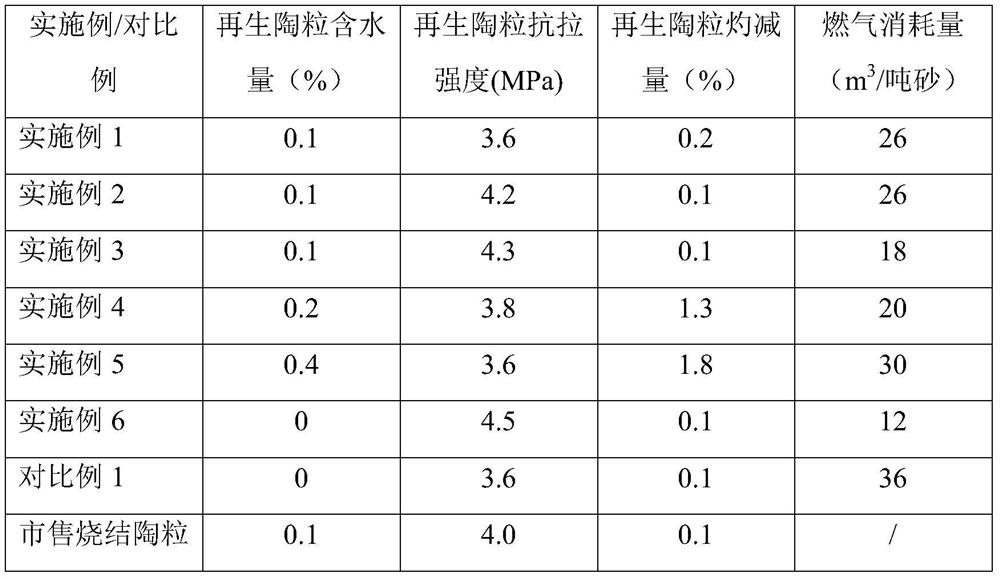

[0038] Change the reaction conditions in Examples and Comparative Examples, see Table 1 for specific settings.

[0039] Table 1 embodiment and comparative example setting

[0040] Example Reaction conditions Example 1 The ceramsite sand is washed in the first stage, dehydrated in the first stage, and dried at 500 °C without wind. Example 2 The ceramsite sand is sequentially washed in two stages, dehydrated in the first stage, and dried at 500°C without wind. Example 3 The ceramsite sand is sequentially washed in two stages, dehydrated in two stages, and dried at 500°C without wind. Example 4 The ceramsite sand is sequentially washed in two stages, dehydrated in two stages, and dried at 200°C without wind. Example 5 The ceramsite sand is sequentially washed in two stages, dehydrated in the first stage, and dried at 200°C without wind. Example 6 The ceramsite sand is sequentially washed in two stages, dehydrated in two stages, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com