Hydrogenation heat gas chemical yield increasing solution component applied to shallow well

A chemical stimulation and solution technology, which is applied in drilling compositions, chemical instruments and methods, wellbore/well components, etc., can solve the problems of low liquid production, secondary damage, and small radius of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

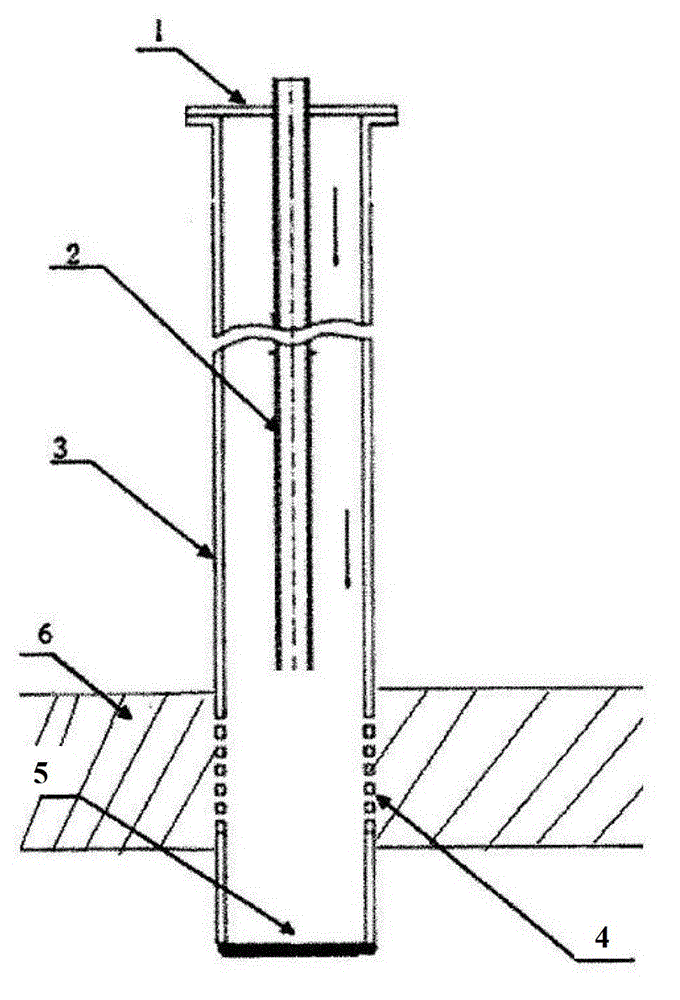

Method used

Image

Examples

Embodiment 1

[0043] Example 1 Stimulation Operation of No. 1 Shallow Well in Jilin Oilfield

[0044] Well No. 1 is a medium-porosity low-permeability reservoir; artificial well bottom 343.5m; perforation range 220.8-226.0m; casing diameter Before the stimulation operation, the daily liquid production is t, of which the daily oil production is t; the known volume per meter of casing: 8.17 liters / m. From the above data, it can be concluded that the volume of the reaction zone is 1.0025m 3. Prepare No. 1 solution 0.55m 3 , No. 2 solution 0.45m 3 , with a mass of 715kg.

[0045] Solution No. 1 (Fuel Oxidizer) Contains: Ammonium Nitrate NH 4 NO 3 , urea CO(NH 2 ) 2 , Decaborane B 10 h 14 , Glucose C 6 h 12 o 6 , cyclohexamethylenetetramine (CH 2 ) 6 N 4 ,water. The respective mass percentages: 43%, 26%, 8%, 2%, 1.5%, 19.5%; the mass of each component is: ammonium nitrate 307.45kg, urea 185.9kg, decaborane 57.2kg, glucose 14.3kg kg, cyclohexamethylenetetramine 10.725kg, water ...

Embodiment 2

[0049] Example 2 Stimulation Operation of No. 2 Shallow Well in Jilin Oilfield

[0050] Well No. 2 is a medium-porosity low-permeability reservoir; artificial well bottom 312.6m; perforation range 256.0-261.0m; casing diameter Before the stimulation operation, the daily liquid production was 1.6t, of which the daily oil production was 0.7t; the known volume per meter of casing: 8.17 liters / m. From the above data, it can be concluded that the volume of the reaction zone is 1.104m 3 . Prepare No. 1 solution 0.497m 3 , No. 2 solution 0.403m 3 , with a mass of 645.5kg.

[0051] Solution No. 1 (Fuel Oxidizer) Contains: Ammonium Nitrate NH 4 NO 3 , urea CO(NH 2 ) 2 , Decaborane B 10 h 14 , Glucose C 6 h 12 o 6 , cyclohexamethylenetetramine (CH 2 ) 6 N 4 ,water. The respective mass percentages: 42%, 25%, 7%, 1.5%, 1%, 23.5%; the mass of each component is: ammonium nitrate 271.11kg, urea 161.375kg, decaborane 45.185kg, glucose 9.6825 kg, cyclohexamethylenetetramine ...

Embodiment 3

[0055] Example 3 Stimulation Operation of No. 3 Shallow Well in Jilin Oilfield

[0056] Well No. 2 is a medium-porosity low-permeability reservoir; artificial well bottom 351.45m; perforation range 250.8-262.0m; casing diameter Before the stimulation operation, the daily liquid production was 1.6t, of which the daily oil production was 0.7t; the known volume per meter of casing: 8.17 liters / m. From the above data, it can be concluded that the volume of the reaction zone is 0.815m 3 . Prepare No. 1 solution 0.386m 3 , No. 2 solution 0.314m 3 , with a mass of 501.8kg.

[0057] Solution No. 1 (Fuel Oxidizer) Contains: Ammonium Nitrate NH 4 NO 3 , urea CO(NH 2 ) 2 , Decaborane B 10 h 14 , Glucose C 6 h 12 o 6 , cyclohexamethylenetetramine (CH 2 ) 6 N 4 ,water. The respective mass percentages: 37%, 23%, 5%, 1%, 0.5%, 33.5%; the mass of each component is: ammonium nitrate 185.6kg, urea 115.41kg, decaborane 25.09kg, glucose 5.02 kg, 2.51kg of cyclohexamethylenetetr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com