Gel plugging agent for deep profile control of higher temperature oil reservoir and preparation method of gel plugging agent

A plugging agent and jelly technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of destroying the polymer jelly network structure, reducing the crosslinking strength of jelly, and affecting the effect of field application, etc., to achieve Simple preparation, little change in strength, and excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

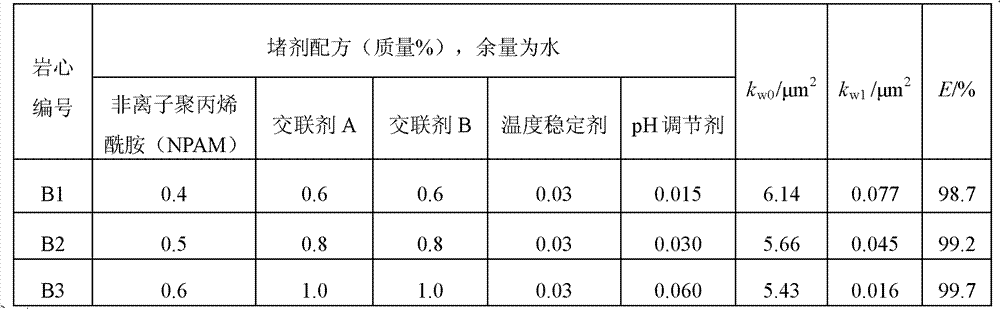

[0035] In 50 g of nonionic polyacrylamide aqueous solution with a mass fraction of 0.4%, add 0.3 g of urotropine solid powder while stirring, then add 0.3 g of hydroquinone solid powder, then add 0.015 g of temperature stabilizer sodium sulfite and stir until All the medicines are dissolved in the aqueous solution, and finally 0.06 g of sodium hydroxide solution (pH regulator) with a mass fraction of 10.0% is added to adjust the pH value of the system to 8.01, and the jelly forming gel of the present invention is obtained by stirring evenly. The jelly has a gelation time of 36 hours at 110° C. and a gelation time of 23 hours at 130° C.

Embodiment 2

[0037] In 50 g of nonionic polyacrylamide aqueous solution with a mass fraction of 0.5%, add 0.4 g of urotropine solid powder while stirring, then add 0.4 g of hydroquinone solid powder, then add 0.015 g of temperature stabilizer sodium sulfite and stir until All the medicines are dissolved in the aqueous solution, and finally 0.17 g of sodium hydroxide solution (pH regulator) with a mass fraction of 10.0% is added to adjust the pH value of the system to 8.48, and the jelly forming gel of the present invention is obtained by stirring evenly. The gelling time of the jelly was 25 hours at 110° C., and 11 hours at 130° C.

Embodiment 3

[0039] In 50 g of nonionic polyacrylamide aqueous solution with a mass fraction of 0.6%, add 0.5 g of urotropine solid powder while stirring, then add 0.5 g of hydroquinone solid powder, then add 0.015 g of temperature stabilizer sodium sulfite and stir until All the medicines are dissolved in the aqueous solution, and finally 0.4 g of sodium hydroxide solution (pH regulator) with a mass fraction of 10.0% is added to adjust the pH value of the system to 8.92, and the jelly forming gel of the present invention is obtained by stirring evenly. The jelly has a gelation time of 21 hours at 110° C., and a gelation time of 8 hours at 130° C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com