Synthetic method of ZnO/WO3 heterojunction arrays

A synthesis method and heterojunction technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, etc., can solve problems such as performance impact, improve efficiency, and broaden capture Range, the effect of improving separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

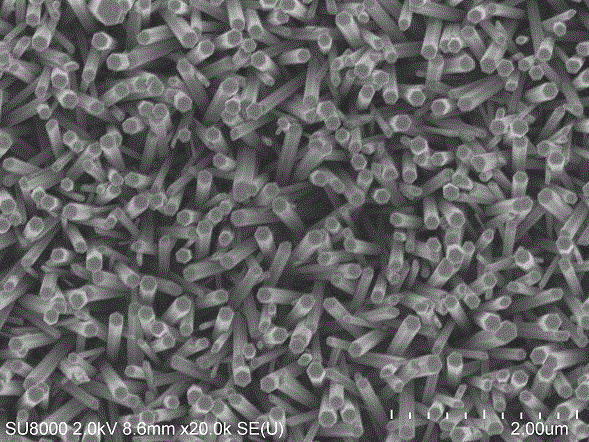

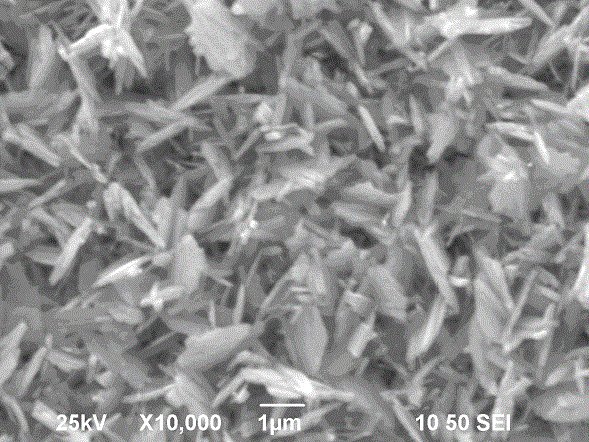

[0016] (1) Add 6.585g zinc acetate to 100mL ethanol solution and stir for 2h, then add 3mL diethanolamine and continue stirring for 2h to obtain a precursor solution, soak the conductive glass (FTO) in the precursor solution for 30min, and get covered ZnO seed crystals the FTO;

[0017] (2) Add 0.5488g of zinc acetate and 0.0517g of polyethyleneimine to 100mL of deionized water and stir in an ice bath for 30min, then add 0.3505g of cyclohexamethylenetetramine and continue stirring for 30min, and finally the step (1) is obtained The FTO covered with ZnO seed crystals was placed in the above solution, heated in an oil bath at 80 °C for 10 h, cooled naturally to room temperature, taken out and cleaned, dried naturally, and then placed in a muffle furnace and annealed at 500 °C for 2 h to obtain growth organic FTO of ZnO nanorod arrays;

[0018] (3) Add 0.25g ammonium paratungstate to 25mL acetic acid and water mixed solution with a volume ratio of 1:1, stir for 10min, then add 0...

Embodiment 2

[0021] (1) Add 6.585g zinc acetate to 100mL ethanol solution and stir for 2h, then add 3mL diethanolamine and continue stirring for 2h to obtain a precursor solution, soak FTO in the precursor solution for 30min to obtain FTO with ZnO seeds;

[0022] (2) Add 0.5488g of zinc acetate and 0.0517g of polyethyleneimine to 100mL of deionized water and stir in an ice bath for 30min, then add 0.3505g of cyclohexamethylenetetramine and continue stirring for 30min, and finally the step (1) is obtained The FTO with ZnO seed crystals was placed in the above solution and heated in an oil bath at 95°C for 5h, cooled naturally to room temperature, the sample was taken out, cleaned and dried naturally, then placed in a muffle furnace and calcined at 500°C for 2h to obtain a ZnO FTO of nanorod arrays;

[0023] (3) Add 0.25g of ammonium paratungstate to 25mL of acetic acid and water mixed solution with a volume ratio of 1:2, stir for 10min, then add 0.5mL of concentrated hydrochloric acid solut...

Embodiment 3

[0025] (1) Add 6.585g of zinc acetate to 100mL ethanol solution and stir for 2h, then add 3mL diethanolamine and continue stirring for 2h to obtain a precursor solution, soak FTO in the precursor solution for 30min to obtain FTO with ZnO seeds;

[0026] (2) Add 0.5488g of zinc acetate and 0.0517g of polyethyleneimine to 100mL of deionized water and stir in an ice bath for 30min, then add 0.3505g of cyclohexamethylenetetramine and continue stirring for 30min, and finally the step (1) is obtained The FTO with ZnO seed crystals was placed in the above solution and heated in an oil bath at 110°C for 1h, cooled naturally to room temperature, the sample was taken out, cleaned and dried naturally, then placed in a muffle furnace and calcined at 500°C for 2h to obtain a ZnO FTO of nanorod arrays;

[0027] (3) Add 0.25g of ammonium paratungstate to 25mL of a mixed solution of acetic acid and water with a volume ratio of 2:1, stir for 10min, then add 0.5mL of concentrated hydrochloric a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com