Pre-coated sand for casting and manufacturing method thereof

A technology of coated sand and raw sand, which is applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc. It can solve the problems of easy sand sticking in castings and poor high-temperature performance of coated sand, so as to improve the yield rate, reduce infiltration, Effect of reducing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

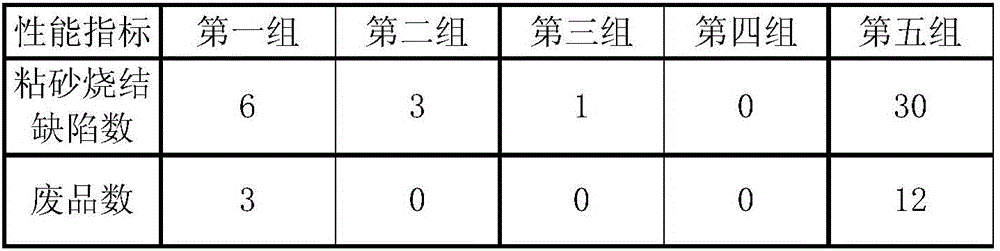

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with embodiment.

[0017] In the coated sand of the present invention, the component content relation of raw sand, phenolic resin, urotropine, and calcium stearate can be based on existing common organic coated sand in raw sand, phenolic resin, urotropine, stearin The components of calcium stearate are configured, for example, with the weight of phenolic resin as a reference, in the coated sand, the weight ratio of the weight of the original sand, urotropine, and calcium stearate to the weight of the phenolic resin is 40-50 (the original sand ), 0.13-0.15 (urotropine), 0.07-0.09 (calcium stearate), and the further component ratio is based on the weight of phenolic resin, the original sand, urotropine, calcium stearate The ratio of weight to phenolic resin weight is 45 (original sand), 0.14 (hexamethylene), 0.08 (calcium stearate)

[0018] The content of the ceramic glaze powder is also based on the we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com