Hydrogenation heat gas chemical yield increasing solution component for low-permeability carbonate reservoir oil well

A carbonate rock reservoir, chemical stimulation technology, applied in drilling compositions, chemical instruments and methods, wellbore/well components, etc., can solve the problems of secondary pollution, high cost, complicated construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

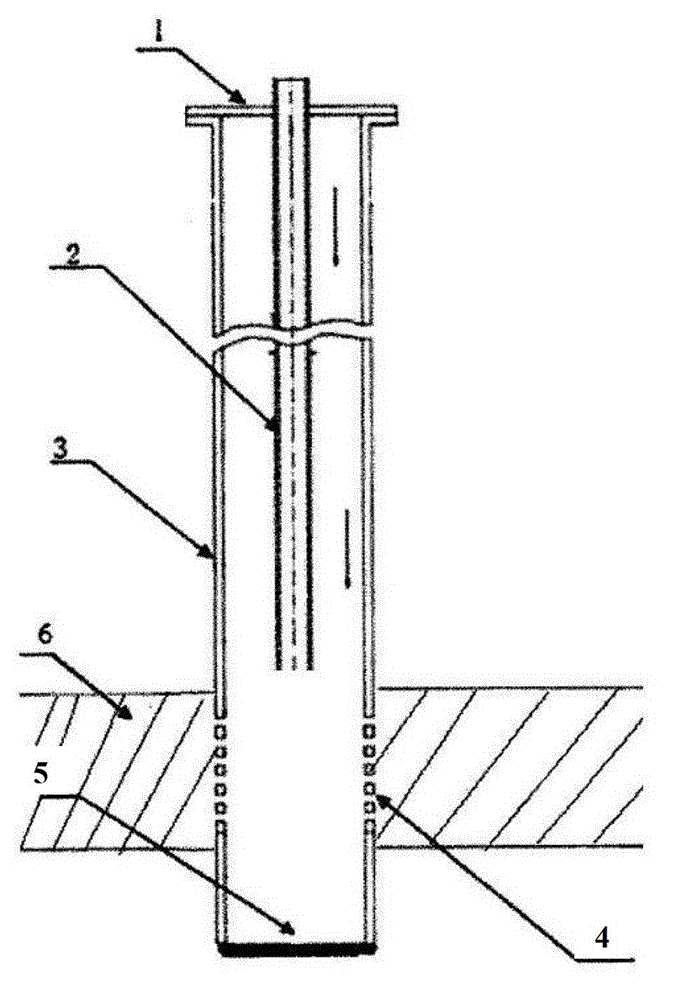

Image

Examples

Embodiment 1

[0042] Example 1: Hydrogenation Hot Gas Chemical Stimulation Test of Oil Well No. 1 in Sichuan Oilfield

[0043]Geological conditions and related parameters of No. 1 oil well: the lithology of the reservoir is mainly gray dolomite, limestone and dolomitic limestone; the average porosity is 9.7%, and the permeability is 46.2×10 -3 μm 2 ;Casing diameter The artificial well bottom is 6648m; the perforation range is 6526-6599m; the daily fluid production before the stimulation operation is 1.6t, of which the daily oil production is 0.3t; from the above data, the volume of the reaction zone is 1464L. Prepare No. 1 solution 780kg, No. 2 solution 780kg, and No. 3 solution 2340kg.

[0044] Solution No. 1 contains: Urea CO(NH 2 ) 2 , sodium nitrite NaNO 2 , hydrazine N 2 h 4 , water H 2 O, the respective mass percentages: 22%, 50%, 13%, 15%; the mass of each component is: urea 171.6kg, sodium nitrite 390kg, hydrazine 101.4kg, water 117kg.

[0045] Solution No. 2 contains: Alu...

Embodiment 2

[0049] Example 2: Hydrogenation Hot Gas Chemical Stimulation Test of Oil Well No. 2 in Sichuan Oilfield

[0050] Geological conditions and related parameters of oil well No. 2: The lithology of the reservoir is mainly gray dolomite, limestone and dolomitic limestone; the average porosity is 7.4%, and the permeability is 11.8×10 -3 μm 2 ;Casing diameter The artificial well bottom is 6801m; the perforation range is 6702-6783m; the daily fluid production before the stimulation operation is 1.2t, of which the daily oil production is 0.1t; the volume of the reaction zone is 1188L from the above data. Prepare No. 1 solution 715kg, No. 2 solution 715kg, and No. 3 solution 2145kg.

[0051] Solution No. 1 contains: Urea CO(NH 2 ) 2 , sodium nitrite NaNO 2 , hydrazine N 2 h 4 , water H 2 O, the respective mass percentages: 26%, 55%, 10%, 9%; the mass of each component is: urea 185.9kg, sodium nitrite 393.25kg, hydrazine 71.5kg, water 64.35kg.

[0052] Solution No. 2 contains: ...

Embodiment 3

[0056] Example 3: Hydrogenation hot gas chemical stimulation test of No. 3 oil well in Sichuan Oilfield

[0057] Geological conditions and related parameters of No. 3 oil well: the lithology of the reservoir is mainly gray dolomite, limestone and dolomitic limestone; the average porosity is 8.1%, and the permeability is 26.4×10 -3 μm 2 ;Casing diameter The artificial well bottom is 6231.5m; the perforation range is 6103-6197m; the daily fluid production before the stimulation operation is 2.0t, of which the daily oil production is 0.18t; the volume of the reaction zone is 1542L from the above data. Prepare No. 1 solution 910kg, No. 2 solution 910kg, and No. 3 solution 2730kg.

[0058] Solution No. 1 contains: Urea CO(NH 2 ) 2 , sodium nitrite NaNO 2 , hydrazine N 2 h 4 , water H 2 O, the respective mass percentages: 24%, 53%, 11%, 12%; the mass of each component is: urea 218.4kg, sodium nitrite 482.3kg, hydrazine 100.1kg, water 109.2kg.

[0059] Solution No. 2 contai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Permeability | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com