Recipe for manufacturing nylon grinding blocks and method for manufacturing nylon grinding blocks by adopting recipe

A grinding block and nylon technology, applied in the direction of abrasives, grinding devices, manufacturing tools, etc., can solve the problems of insufficient bonding force between epoxy resin and silicon carbide, affecting the service life of nylon grinding blocks, and non-wearing nylon grinding blocks. Achieve the effects of improving polishing efficiency, enhancing wear resistance, and enhancing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

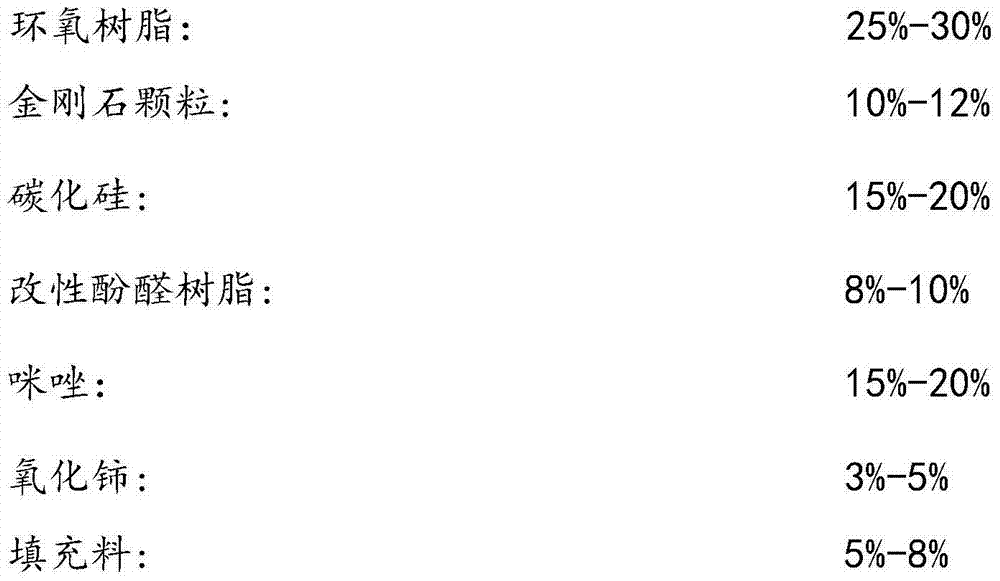

Embodiment 1

[0032] The following raw materials are configured by weight percentage: 30% of epoxy resin, 12% of diamond particles, 18% of silicon carbide, 8% of modified phenolic resin, 20% of imidazole, 5% of cerium oxide, and 7% of zinc oxide. Wherein the modified phenolic resin is composed of the following three substances in weight percentage: 13% of urotropine, 4% of polyimide and 83% of phenolic resin. The diamond particles can be diamond particles with a particle size ranging from 20 / 24 to 800 / 1000, which is not specifically limited here.

[0033] Specifically, configure as follows:

[0034] First, put block-like phenolic resin, block-like polyimide and crystal-like urotropine into the ball mill according to the above ratio, and ball-mill the three into a powder mixture; send the ball-milled mixture into the kneading machine for mixing, the mixing temperature is 80°C, and the mixing time is 30 minutes to form a modified phenolic resin.

[0035] Next, mix the diamond, silicon carbi...

Embodiment 2

[0039] The following raw materials are configured by weight percentage: 29% of epoxy resin, 12% of diamond particles, 19% of silicon carbide, 10% of modified phenolic resin, 19% of imidazole, 4% of cerium oxide, and 7% of zinc oxide. Wherein the modified phenolic resin is composed of the following three substances in weight percentage: 14% of urotropine, 3% of polyimide and 83% of phenolic resin.

[0040] Specifically, it can be configured in the following ways:

[0041] First, put block-like phenolic resin, block-like polyimide, and crystalline urotropine into the ball mill according to the above ratio, and ball-mill the three into a powder mixture; send the ball-milled mixture into the kneading machine for mixing, the mixing temperature is 100°C, and the time is 20 minutes to form a modified phenolic resin.

[0042] Next, mix the diamond, silicon carbide, imidazole, zinc oxide, cerium oxide and modified epoxy resin in the above ratio, add it into the liquid epoxy resin afte...

Embodiment 3

[0046] The following raw materials are configured by weight percentage: 26% epoxy resin, 12% diamond particles, 20% silicon carbide, 10% modified phenolic resin, 20% imidazole, 5% cerium oxide, and 7% zinc oxide. Wherein the modified phenolic resin is composed of the following three substances in weight percentage: 14% of urotropine, 3% of polyimide and 83% of phenolic resin.

[0047] The above proportioned raw materials are configured with the same configuration sequence and process conditions as in Example 2; after the formulation configuration is completed, the same process and sequence as in Example 2 are used to make nylon grinding blocks. That is, the difference between the third embodiment and the second embodiment is that the proportioning ratio of the formula for making the nylon grinding block is different, and the nylon grinding block made in the third embodiment can grind stones with a length of 160 meters.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com