Quick cooling device for sand of lost-foam production line

A rapid cooling and production line technology, which is applied in the direction of casting molding equipment, cleaning/processing machinery for casting mold materials, metal processing equipment, etc., can solve the problems of cooling equipment occupying a large production site, increasing production costs, and high procurement costs. Achieve good cooling effect, low cost, and reduce production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

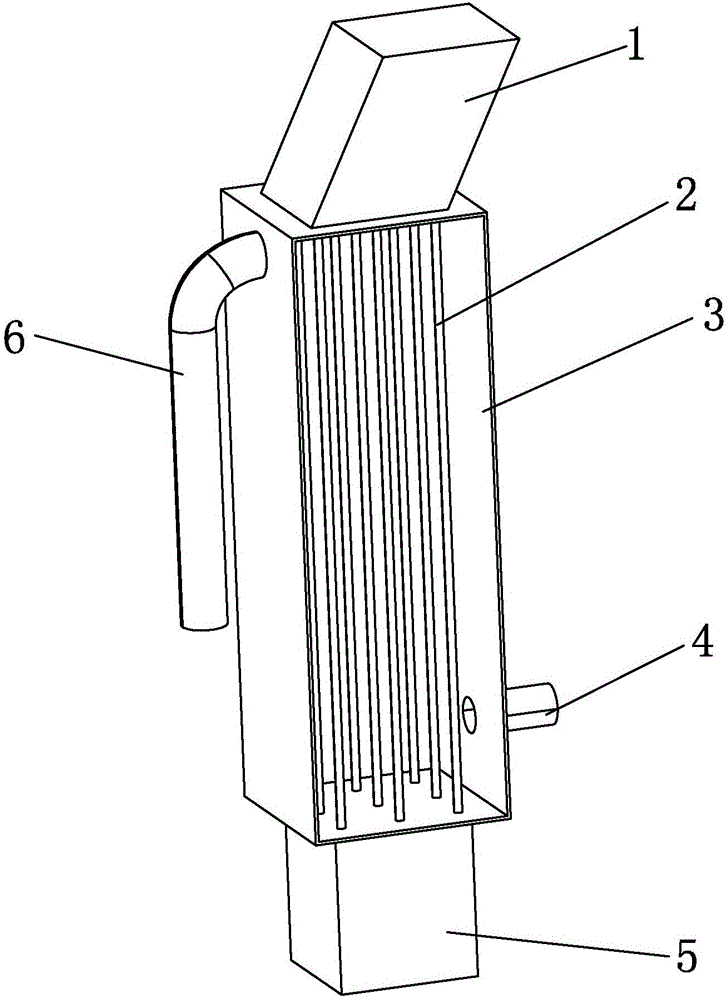

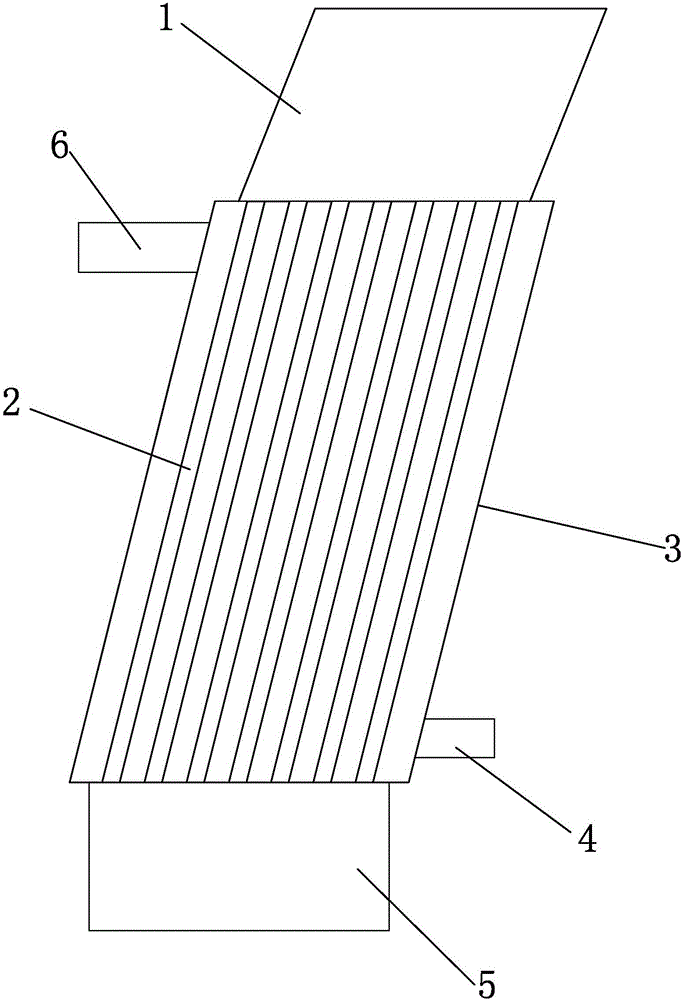

[0017] Such as figure 1 As shown, the sand rapid cooling device of the lost foam production line of the present invention (referred to as "rapid cooling device") includes a cooling water tank 3, a sand cooling metal pipe 2, a sand inlet bucket 1, and a sand outlet bucket 5.

[0018] The tank wall near the top of the cooling water tank 3 is connected with an outlet pipe 6 connected to the inside of the cooling water tank 3 , the tank wall near the bottom of the cooling water tank 3 is connected with an inlet pipe 4 connected to the inside of the cooling water tank 3 , and a cooling water pool is arranged outside the outlet pipe 6 (not shown in the figure), a water pump (not shown in the figure) is connected to the water inlet pipe 4, and the water inlet of the water pump is connected to the cooling water pool through a pipeline, so that the cooling water in the cooling water tank 3 circulates. The sand feeding hopper 1 is connected to the outer surface of the top wall of the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com