Regeneration technology of foundry used sand

A process and technology of used sand, applied in the field of regeneration process of used foundry sand, can solve the problems of affecting magnetic absorption, reducing the strength of sand core, large acid consumption value, etc. The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

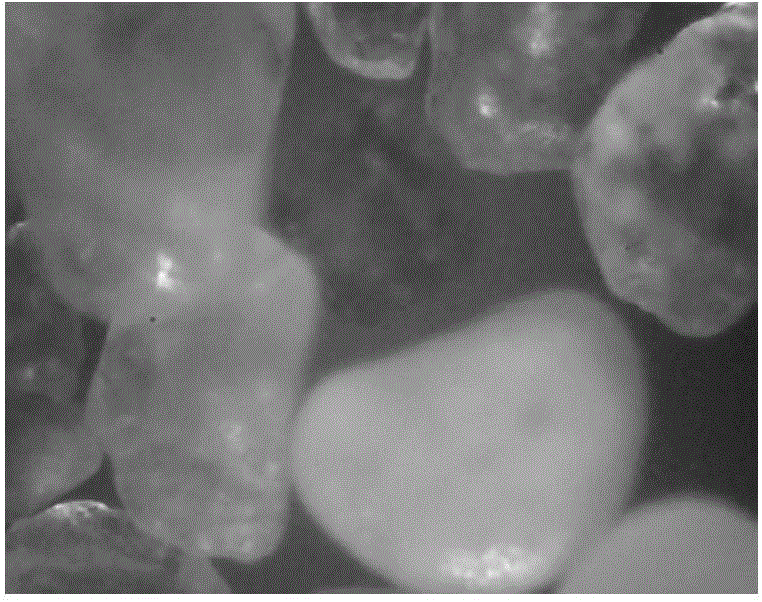

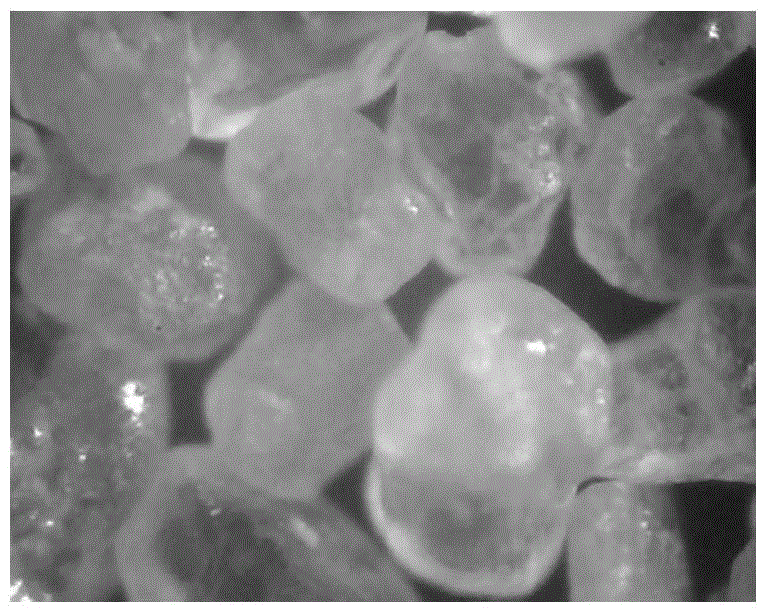

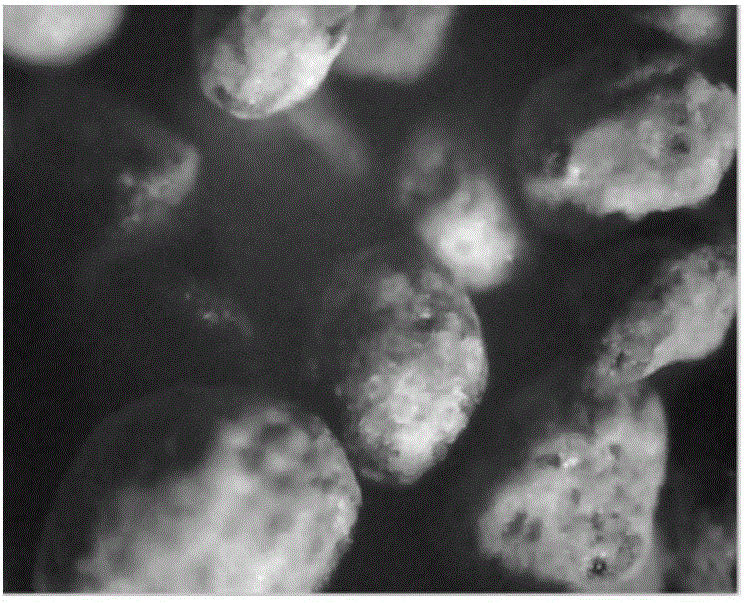

Image

Examples

Embodiment 1

[0031] A regeneration process for foundry old sand, comprising the steps of:

[0032] 1) Carrying out the primary magnetic separation of the broken old sand to remove the coarse magnetic substance mixed in the old sand; the magnetic induction of the magnetic separation is 3000 gauss;

[0033] 2) roasting the old sand after the initial magnetic separation; the roasting process conditions: the temperature is 700°C, and the roasting time is 5.5 hours;

[0034] 3) Cool the calcined sand particles to 130°C with water mist, continue ventilating and blasting at the bottom of the grinder, and at the same time continuously pump air at the top of the grinder, so that an airflow is formed in the grinder to make the sand particles boil, and the pressure is controlled at - 4.5KPa, to remove impurities such as dead ash produced when the surface of the sand is roasted;

[0035] 4) Sieve the ground sand through 20 meshes and then magnetically separate again; the magnetic induction intensity ...

Embodiment 2

[0037] Adopt the method for embodiment 1 to prepare reclaimed sand, difference is:

[0038] 1) The roasting temperature in step 2) is 500°C, and the roasting time is 5 hours;

[0039] 2) Mechanical grinding process conditions in step 3): negative pressure of -4KPa is formed in the grinding machine;

[0040] 3) The magnetic induction intensity of magnetic separation in step 4) is 10000 Gauss, and the amount of sand feeding is 5T / h,

[0041] The sand thickness is 3mm.

Embodiment 3

[0043] Adopt the method for embodiment 1 to prepare reclaimed sand, difference is:

[0044] 1) The roasting temperature in step 2) is 800°C, and the roasting time is 6 hours;

[0045] 2) Mechanical grinding process conditions in step 3): -5KPa negative pressure is formed in the grinding machine;

[0046] 3) The magnetic induction intensity of magnetic separation in step 4) is 13000 gauss, and the amount of sand feeding is 2T / h,

[0047] The sand thickness is 1mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic induction | aaaaa | aaaaa |

| Magnetic induction | aaaaa | aaaaa |

| Magnetic induction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com